|

| ||

| The Ovation Fan Club | ||

| ||

| Random quote: "It's much too late to do anything about rock & roll now ..." - Jerry Garcia / Grateful Dead |

1985 1717 Legend Rebuild... 1985 1717 Legend Rebuild...

| View previous thread :: View next thread | |

| Member Communities -> Bottom Feeding Luthiery Guild | Message format | |

| DanSavage |

| ||

Joined: June 2012 Posts: 2303 Location: Lake Forest, CA | In addition to the 1974 1111, I'll be rebuilding a 1985 Legend at the same time

The braces I'm going to use on this guitar will be a hybrid of the two styles. I'll use the wider, notched cross-brace with the fiberglass reinforcements. The fan braces will have the tapered scalloped profile, but without the milled cross-section. I could make a tool to mill the wood, but I suspect the cross-section had more to do with reducing warranty work than with sound quality. Edited by DanSavage 2016-09-25 4:34 PM | ||

| |||

| 2wheeldrummer |

| ||

Joined: February 2014 Posts: 699 Location: moline,illinois | Very cool pics of the A-bracing and evolution over the years,do you have a CL bridge for this one or will you make your own? | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2303 Location: Lake Forest, CA | Thanks. I already have the bridge and the pick-up. | ||

| |||

| SillyLittleBoy |

| ||

Joined: July 2013 Posts: 98 Location: Des Moines, Iowa | I've not really thought a lot about the bracing, though I've been aware of the different patterns and all. In looking at these two my initial un-educated thoughts are that the LX bracing would allow for more of the top to be free/open and possibly provide for a fuller or thicker tone? There's just not much room between the braces with the fan pattern, whereas the LX bracing provides for some larger unhindered surface area for the top. It would seem that the top would resonate a bit more with the LX because of this fact. Is any of this actually true? Very interesting... maybe... | ||

| |||

| leonardmccoy |

| ||

Joined: December 2015 Posts: 287 Location: Katmandu | The 2077AV50 is so cleanly braced -- not a single drop of excess glue -- it puts a lot of other guitars to shame. When I checked out a Gibson LG1 (or LG2) by chance recently, I couldn't believe my eyes how poorly the bracing was glued to the top and back. | ||

| |||

| Love O Fair |

| ||

Joined: February 2016 Posts: 1769 Location: When?? | I fully agree with Leonard... so incredibly clean... looks like something straight from the NASA white room. If that were my guitar I would print the photo and tuck it inside a thank you card mailed directly to the mother ship on behalf of those of us who admire their dedicated craftsmanship. I'm sure they'd all appreciate that. | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2303 Location: Lake Forest, CA | After I got the guitar, I sent a note to the MS complimenting them on the fit and finish of these anniversary guitars. IMO, they're as nice as anything I've seen. | ||

| |||

| arumako |

| ||

Joined: October 2012 Posts: 1018 Location: Yokohama, Japan | DanSavage - 2016-10-03 1:50 AM After I got the guitar, I sent a note to the MS complimenting them on the fit and finish of these anniversary guitars. IMO, they're as nice as anything I've seen. Hi Dan! Looking forward to following your progress. What kind of mirror is that? Looks really useful! I want one! | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2303 Location: Lake Forest, CA | Hi Ken, Thanks. I haven't been able to work on these guitars this week due to prior commitments, but I'm back on the job now. That's the Stewmac 3-piece folding inspection mirror. http://www.stewmac.com/Luthier_Tools/Tools_by_Job/Tools_for_Inspect... It's basically just three identical strips of mirrored plexiglass that are taped together so they z-fold into a strip that's narrow enough to fit through the sound hole. Once inside the guitar, you just unfold it. You could probably just make one yourself by going down to a local glass/mirror shop and having them cut three strips of mirrored plastic. What I think is a really slick tool is their LED inspection light. It's got either 4 or 5 levels of brightness, is oct-shaped so it doesn't roll around, has built-in magnets and charges from a USB port or charger. http://www.stewmac.com/Luthier_Tools/Tools_by_Job/Tools_for_Inspect... Edited by DanSavage 2016-10-03 5:25 PM | ||

| |||

| DetlefMichel |

| ||

Joined: May 2011 Posts: 751 Location: Muenster/Germany | The glue-drops at the end of the braces remind me to my old Gibson Mark guitar with the Kasha braces. I learned from you a lot about the forward-shifted x. Do you have any improvements for the classic A-braces in mind? I wouldn´t be surprised if your new topped "DS-A-BRACE" would easily blow off any other Legend Ovation... | ||

| |||

| DetlefMichel |

| ||

Joined: May 2011 Posts: 751 Location: Muenster/Germany | Another example of A-braces:

2. old custom legend 1619 (looks awful, sounds better)

| ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2303 Location: Lake Forest, CA | DetlefMichel - 2016-10-06 8:55 AM The glue-drops at the end of the braces remind me to my old Gibson Mark guitar with the Kasha braces. I learned from you a lot about the forward-shifted x. Do you have any improvements for the classic A-braces in mind? I wouldn´t be surprised if your new topped "DS-A-BRACE" would easily blow off any other Legend Ovation... Except for using torrefied wood for the top and braces, I have nothing special planned for this. Since I don't have a way to mill scalloped cross-section, the fan braces will be like the early 1619. It will be a hybrid of the original 1619 and the later using the fiberglass reinforcements for the upper and lower A-braces and notched cross-brace, but with flat a-braces. As with all my guitars I will be using OBG to joint the halves and to glue the braces to the underside of the top. Not sure yet if I'm going to put glue-globs on the ends of the A-braces or not. Yes, I'm really looking forward to hearing how a torrefied A-brace O sounds. Edited by DanSavage 2016-10-06 12:02 PM | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2303 Location: Lake Forest, CA | Thanks for the pics. DetlefMichel - 2016-10-06 9:15 AM Another example of A-braces: | ||

| |||

| leonardmccoy |

| ||

Joined: December 2015 Posts: 287 Location: Katmandu | Detlef's photos just reminded myself that I wanted to remove the bridge's screw nuts of my Legend entirely so that when the bridge someday does decide to come off the top it can do so freely and without ripping the well-aged top apart in the process. Edited by leonardmccoy 2016-10-06 3:54 PM | ||

| |||

| DetlefMichel |

| ||

Joined: May 2011 Posts: 751 Location: Muenster/Germany | Do you want to sell this guitar when it´s ready? | ||

| |||

| DetlefMichel |

| ||

Joined: May 2011 Posts: 751 Location: Muenster/Germany | I forgot to tell you that I meanwhile carefully fine-sanded the braces, I cannot live with such a mess, and see the real big hole in the top where the cables come out. It was so big that the low E string had barely material under it. The stereo pickup was broken anyway so I decided to transform the guitar into an acoustic.I filled the drilling hole with top-wood,

But enough from me, now I`m eager to see upcoming sequels of your new guitar series, which I follow just like I did with "Breaking Bad" | ||

| |||

| moody, p.i. |

| ||

Joined: March 2002 Posts: 15653 Location: SoCal | Looks very cool. How does it sound? Does the saddle go all the way down to the guitar top? | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2303 Location: Lake Forest, CA | DetlefMichel - 2016-10-07 8:14 AM Do you want to sell this guitar when it´s ready? In all fairness, it's already spoken for. But, if that buyer decides not to take it, you're second on the list. I'm not going to name the buyer. If they choose to come forward, that's up to them. | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2303 Location: Lake Forest, CA | DetlefMichel - 2016-10-07 8:38 AM I forgot to tell you that I meanwhile carefully fine-sanded the braces, I cannot live with such a mess, and see the real big hole in the top where the cables come out. It was so big that the low E string had barely material under it. The stereo pickup was broken anyway so I decided to transform the guitar into an acoustic.I filled the drilling hole with top-wood, Nice job on the conversion. Yes, the stereo pick-up does need a rather large hole because of the size of the cables. | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2303 Location: Lake Forest, CA | I jointed the top wood for this guitar today. I've made an appointment with my sanding guy for Monday to thickness sand the top.

| ||

| |||

| 2wheeldrummer |

| ||

Joined: February 2014 Posts: 699 Location: moline,illinois | Very cool work as usual,if you tried to adapt the A-bracing to a 12 string would you add an extra cross brace by the bridge to support the extra tension.I've always wanted an A-braced Custom Legend 12 string and have been on the lookout for parts to create one. | ||

| |||

| arumako |

| ||

Joined: October 2012 Posts: 1018 Location: Yokohama, Japan | Hi Dan! Thanks for sharing another very very cool project. Hope you don't mind a few questions...How thick are the aluminum reinforcements and did you perforate them yourself? Will you fine tune the bracing with your chisel after you mount them to the sound board or are they pretty much in their final condition? Really enjoyable stuff! | ||

| |||

| tpa |

| ||

Joined: December 2004 Posts: 555 Location: Denmark | Aluminum pieces are angled and glued to the outfacing sides of the bracing, I suppose. Apparently the ADII uses Alu reinforcements with varying success. http://www.ovationfanclub.com/megabbs/forums/thread-view.asp?tid=44... Edited by tpa 2016-10-08 6:59 AM | ||

| |||

| DanSavage |

| ||

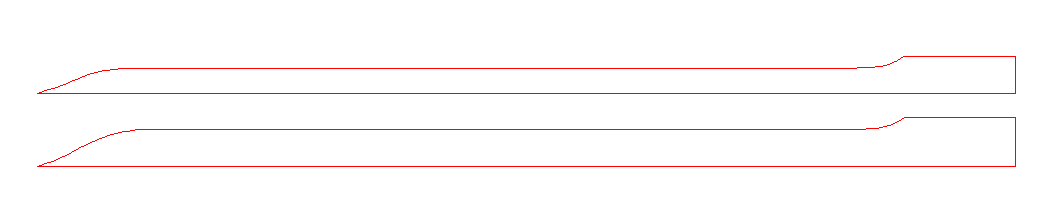

Joined: June 2012 Posts: 2303 Location: Lake Forest, CA | 2wheeldrummer - 2016-10-07 8:31 PM Very cool work as usual,if you tried to adapt the A-bracing to a 12 string would you add an extra cross brace by the bridge to support the extra tension.I've always wanted an A-braced Custom Legend 12 string and have been on the lookout for parts to create one. Thanks, Kevin. I never really thought about what changes would be made for an A-brace 12-string. I don't think an extra cross-brace at the bridge would do much to prevent bellying. Maybe just make these fan braces taller in cross-section. Here's a drawing that shows what changes I would make. The top brace is the A-brace pattern I used. The bottom one is what I would use if I were to make an A-brace 12-string. The tallest part of the upper brace is 3/8" and tapers down to 1/4". The tallest part of the lower brace is 1/2" and tapers down to 3/8". I would also make all of the other brace wood 1/2" thick instead of the 3/8" it is now.

A while ago I read the patent description for Adamas quintaid bracing pattern. One of the things I remember is the description of how a guitar top vibrates. Basically, it twists in torsion. The quintaid braces allow more twisting and the lack of a center sound hole prevents the top from warping due to string tension. The A-brace looks to me, like a quintaid brace pattern that allows for a center sound hole. It seems to me that using taller braces that are still 1/8" thick, like the fan braces would help prevent the top from warping due to extra string tension, but still allow it to twist.

Edited by DanSavage 2016-10-08 10:09 AM | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2303 Location: Lake Forest, CA | arumako - 2016-10-07 9:08 PM Hi Dan! Thanks for sharing another very very cool project. Hope you don't mind a few questions...How thick are the aluminum reinforcements and did you perforate them yourself? Will you fine tune the bracing with your chisel after you mount them to the sound board or are they pretty much in their final condition? Really enjoyable stuff! Thanks, Ken. The aluminum braces are 1/32" thick. (.032" or .8mm) Nope. These came from the MS just as you see them. The braces are in their final configuration. These are pretty close approximations of the fan braces you see on the sound board to the left. | ||

| |||

| Jump to page : 1 2 3 4 5 Now viewing page 1 [25 messages per page] |

| Search this forum Printer friendly version E-mail a link to this thread |

| This message board and website is not sponsored or affiliated with Ovation® Guitars in any way. | |

| (Delete all cookies set by this site) | |

and cut a nut for a bone saddle.

and cut a nut for a bone saddle. The guitar now sounds better than ever.

The guitar now sounds better than ever.