|

| ||

| The Ovation Fan Club | ||

| ||

| Random quote: "There are more love songs than anything else. If songs could make you do something we'd all love one another." -Frank Zappa |

EVO Gold frets on a Deacon EVO Gold frets on a Deacon

| View previous thread :: View next thread | |

| Member Communities -> Bottom Feeding Luthiery Guild | Message format | |

| FlySig |

| ||

Joined: October 2005 Posts: 4079 Location: Utah | EVO Gold fretwire is a harder metal alloy than regular nickel silver frets but not as hard as stainless steel. All regular fretting tools can be used on EVO without problems or excess wear. EVO contains no Nickel which means it is non-allergenic. Buying EVO is a bit frustrating. There are not many sellers, and most of them sell pre-cut and pre-radiused frets. Most sell them in 24 fret packages, which means there is no extra in the event of damage or mistake when working on a 24 fret neck such as the Deacon has. Luthiers Mercantile sells uncut lengths of EVO wire. https://www.lmii.com/products/tools-services/fretting/fretwire/gold-... 43080 is the wire I chose. Unfortunately EVO does not offer a wire which is a perfect match to Ovation / Adamas factory original, but this wire with a crown height of .043" is close enough. Another choice would be the 55090, though that would be a bit on the tall side for me. Somewhere right between those two heights would have been perfect. EVO is easy to sand down and recrown, so in the future I will likely try the 55090. Luthier's Mercantile sent the wire in a coil with a radius that matched the 10" fretboard radius, so no further radiusing was needed before installing it. But do check the radius carefully because EVO needs to match the fretboard closely. EVO does not bend when installed the way nickel silver does, so you don't want to over-radius it the way you do with nickel silver. | ||

| |||

| FlySig |

| ||

Joined: October 2005 Posts: 4079 Location: Utah | So this is what I started with, a neck which had been refretted at least once, and the frets filed and leveled at least once. Plus lots of wear. The fret ends were rising, which snagged the high E string. Due to the damage and age of the binding, a previous owner had filed back the fret ends, reducing the effective width of the fretboard. Here are some picture before starting.    The first task was to remove all the frets and then replace the binding. The binding work is chronicled in another thread at http://www.ovationfanclub.com/megabbs/forums/thread-view.asp?tid=40... Edited by FlySig 2014-10-11 10:39 AM | ||

| |||

| FlySig |

| ||

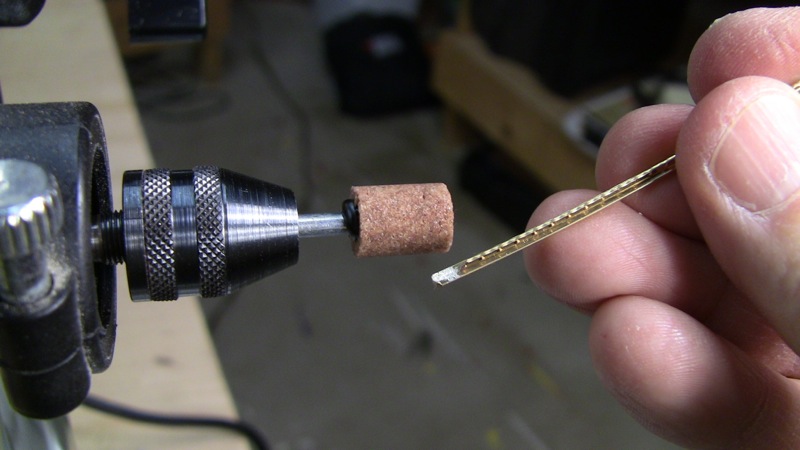

Joined: October 2005 Posts: 4079 Location: Utah | Because of the binding, the ends of the fret tangs have to be removed. With EVO this becomes a bit of a chore. Normally the end of the tang is nipped off, and then the underside of the crown is filed flat so it will sit flush against the binding. However the EVO is very slow to file compared to nickel silver. The quickest method is to use a dremel tool and a small grinding stone. The smaller diameter stone works best. I ruined a couple of frets using a larger stone because it is difficult to be accurate with the larger stone. Each fret has to be precisely prepared. I found it easier to prepare all of the frets prior to installing any, so I used a little wood block to hold the frets and keep them organized.   Working with EVO is definitely different than nickel silver. Nipping off the tang is easier with EVO because the wire is stiff enough not to bend. Nickel silver tends to take a bend at the tip when nipping off the tang using regular fret wire cutters. There is an expensive nipping tool which probably prevents this problem. But EVO doesn't distort when nipping off that tang with regular wire cutters. Installing the frets is easier with EVO because the wire doesn't dent or kink when struck with the hammer. It also doesn't flex when installed, so it simply goes in properly and easily. One complication caused by the binding is that glue has nowhere to escape when the fret is installed. Without binding the excess glue just squirts out the side of the slot. I used slightly diluted carpenter's glue for this job, and only put a small amount in each slot. A few frets weeped glue up and along the entire length of the fret. The glue wiped away easily enough but those frets didn't seem to seat fully down into the slot. | ||

| |||

| FlySig |

| ||

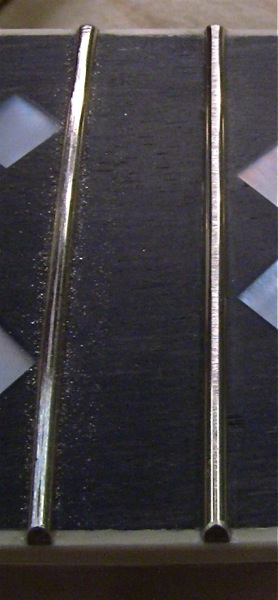

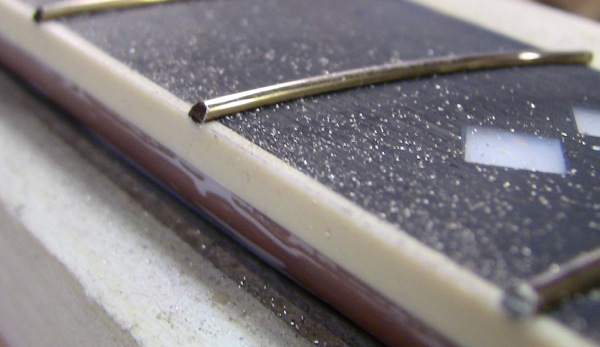

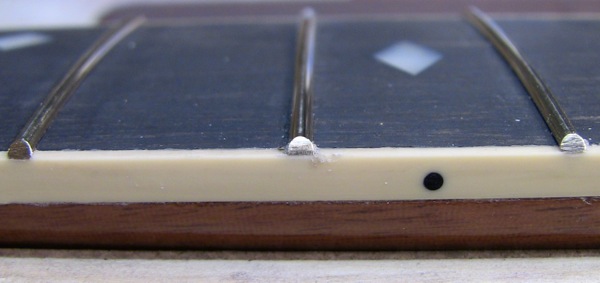

Joined: October 2005 Posts: 4079 Location: Utah | One nice feature of working with EVO is that I found the fretboard did not need to be masked with blue tape. This was a big time saver. Another nice feature of EVO on a bound neck is not having to end file the fret flush to the side of the neck before beveling the ends of the frets. So once the frets were glued in, I leveled them using a sanding beam and 320 grit paper. The EVO sands quite easily, leaving a distinctive looking stripe along the top of the wire. No need to use a blue or black Sharpie on the tops of all the frets prior to leveling. So there is another time saver with EVO, plus no need to put on blue masking tape as a precaution against slipping with the Sharpie and staining the wood blue! The sanding stripe is hard to photograph well. It is actually a lot more visible to the eye than the picture shows. The fret on the right has the sanding stripe, whereas the fret on the left does not.  After sanding level, I beveled the ends of the frets. To protect the edge of the binding from being damaged by the file, I ran a piece of scotch tape along the edge of the binding, snug up against the bottoms of the overhanging fret ends. This worked perfectly. When the frets were filed even with the binding, the file slid easily on the tape, which was easy to feel. Thus it was easy to not go to far with the file. After beveling, remove the tape. Here's the edge after beveling before removing the tape.  A few of the beveled ends needed to be cleaned up with an end file. The plastic binding was very resistant to file damage, though I took a lot of care not to cut into it. Clearcoat on wood shows scuffs a lot more dramatically than the plastic binding does. Here's a before and after picture of one of such fret.   Edited by FlySig 2014-10-11 11:27 AM | ||

| |||

| FlySig |

| ||

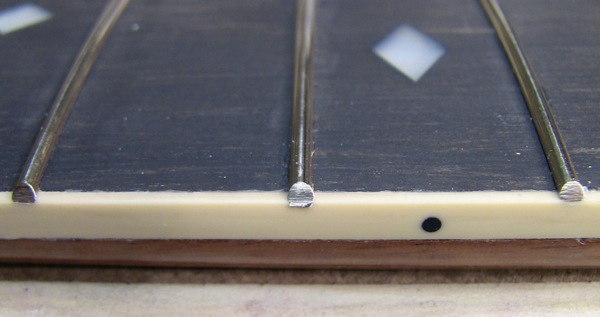

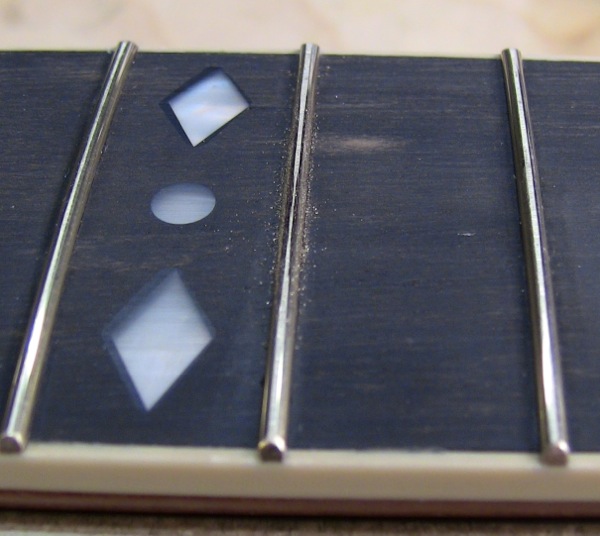

Joined: October 2005 Posts: 4079 Location: Utah | The last steps were to smooth the fret ends with a small file, recrown the frets, and polish them. The fret ends filed smooth a lot more easily than nickel silver. The EVO seems to smooth without having to remove as much material as nickel silver. The plastic binding doesn't mark like wood does, so this was a quick task to smooth those ends. With nickel silver it takes more time per fret. Also with a non-bound neck one should use masking tape along each fret to prevent damage to the wood when filing the edges. EVO on a bound neck means no masking tape and easy fret end smoothing. Crowning was surprisingly easy, fast, and simple compared to nickel silver. Again, no need to use blue masking tape to cover the entire fretboard! No need to use a blue or black sharpie across the top of each fret. The sanding line is very easy to see, and it is very easy to see when the fret is crowned properly. It was actually fun to crown these frets! In the following picture the center fret is partially crowned. The two outer frets are sanded but not crowned yet. The center section of the center fret is almost crowned enough, leaving just a narrow bit of the sanding line. The remainder of that center fret is not yet crowned, so you can see how the sanding line disappears as the fret is crown filed. This is way easier than trying to see a blue sharpie line on a nickel silver fret.  To polish the frets I used the StewMac micro-mesh soft polishing pads. Edited by FlySig 2014-10-11 11:43 AM | ||

| |||

| FlySig |

| ||

Joined: October 2005 Posts: 4079 Location: Utah | So here are the before and after pictures. All that's left today is to finish making a new nut, and start playing! Before  After  Before  After  Before  After  Edited by FlySig 2014-10-11 11:38 AM | ||

| |||

| standing |

| ||

Joined: December 2008 Posts: 1456 Location: Texas | Nice work, FlySig! Your detailed explanations and photos are very informative and inspiring. | ||

| |||

| 2wheeldrummer |

| ||

Joined: February 2014 Posts: 715 Location: moline,illinois | Beautiful work I really like the way the gold frets compliment the neck.Excellent descriptions you and dan savage should open a shop. | ||

| |||

| marenostrum |

| ||

Joined: August 2007 Posts: 1008 Location: Tuscany, Italy | 2wheeldrummer - 2014-10-10 11:03 PM Beautiful work I really like the way the gold frets compliment the neck.Excellent descriptions you and dan savage should open a shop. +1 I will surely ship any of my guitars to you. Bravo. (shhh do not tell to MS)..... | ||

| |||

| TAFKAR |

| ||

Joined: April 2008 Posts: 2985 Location: Sydney, Australia | My Adamas 1680 came standard with goldish frets. Would that be EVO? | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2344 Location: Pueblo West, CO | Nice! I love the gold frets. I know I'll have to re-fret the 1617 project I just bought, so it looks like Evo is the way to go. (It's missing the freboard binding, so the frets gotta come out before it gets rebound --Of course, it's also missing the top, so there's that to do, too...) I looked at the page on LMI that you linked, but didn't see 43080. Is this known by a different number now? BTW, what are the basic dimensions of the frets used on Os? | ||

| |||

| FlySig |

| ||

Joined: October 2005 Posts: 4079 Location: Utah | richard.parker - 2014-10-12 3:58 PM My Adamas 1680 came standard with goldish frets. Would that be EVO? I'm no expert on the universe of fret wire, but I have the only goldish colored wire I've seen is the EVO. | ||

| |||

| FlySig |

| ||

Joined: October 2005 Posts: 4079 Location: Utah | DanSavage - 2014-10-12 7:17 PM Nice! I love the gold frets. I know I'll have to re-fret the 1617 project I just bought, so it looks like Evo is the way to go. (It's missing the freboard binding, so the frets gotta come out before it gets rebound --Of course, it's also missing the top, so there's that to do, too...) I looked at the page on LMI that you linked, but didn't see 43080. Is this known by a different number now? BTW, what are the basic dimensions of the frets used on Os? LMII calls it FW74GOLD for some reason. The EVO numbering system is quite logical actually. 43080 has a crown height of .043" and a crown width of .080" . The next size up is the 55090. My recent O/A and Hamer factory frets run .048" tall and .095" wide. Older O's have smaller wire but I don't have any with the originals on them any more so I can't measure them. | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2344 Location: Pueblo West, CO | Gotcha! Thanks for the info. | ||

| |||

| FlySig |

| ||

Joined: October 2005 Posts: 4079 Location: Utah | I have a pdf of the Ovation engineering drawing for fretwire, dated 5/5/92, which shows a crown height of .040" and a width of .078". | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2344 Location: Pueblo West, CO | Kewl! It's good to know that the EVO 43080 fret wire is nearly identical to the OEM fret wire. | ||

| |||

| arumako |

| ||

Joined: October 2012 Posts: 1093 Location: Yokohama, Japan | FlySig - 2014-10-12 10:44 PM The EVO numbering system is quite logical actually. 43080 has a crown height of .043" and a crown width of .080" . The next size up is the 55090. FlySig - 2014-10-12 11:28 PM I have a pdf of the Ovation engineering drawing for fretwire, dated 5/5/92, which shows a crown height of .040" and a width of .078". Ahhh, a wealth of information...Thanks FlySig! | ||

| |||

| Jump to page : 1 Now viewing page 1 [25 messages per page] |

| Search this forum Printer friendly version E-mail a link to this thread |

| This message board and website is not sponsored or affiliated with Ovation® Guitars in any way. | |

| (Delete all cookies set by this site) | |