|

| ||

| The Ovation Fan Club | ||

| ||

| Random quote: "One good thing about music, when it hits you, you feel no pain." - Bob Marley |

198? 1528-9 Ultra... 198? 1528-9 Ultra...

| View previous thread :: View next thread | |

| Member Communities -> Bottom Feeding Luthiery Guild | Message format | |

| Love O Fair |

| ||

Joined: February 2016 Posts: 1881 Location: When?? | Dan & Daren.. great looking family! What do your hats say on them? Greta's thoughts: "I really hate it when that weird little box flashes light at me... and I think it's about to do it again!" | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2340 Location: Pueblo West, CO | Thanks.

| ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2340 Location: Pueblo West, CO | Top being glued to the bowl. Yes, that's the 1117-4 top being glued at the same time. If I had more bench space I would have glued the other two tops at the same time. | ||

| |||

| DarenSavage |

| ||

Joined: December 2016 Posts: 128 | Whoo hoo! The back looks the same, but I bet the front looks very different. | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2340 Location: Pueblo West, CO | Actually, pretty similar. What is different about these four guitars is how the tops sound when they're tapped. Paul's 1117 is the most hollow sound, followed by the 1612. This isn't really surprising because they're both deep bowls with similar brace patterns. I attribute the difference to the Adi top and hand-laid bowl on the 1117, with the Sitka spruce top and SMC bowl on the 1612. Next is the 1778T, followed by your 1518. Again, not surprising because the 1778T is a medium depth bowl and yours is a super-shallow bowl. Don't get me wrong, they all will sound great. Just different from each other. Edited by DanSavage 2017-02-27 6:14 PM | ||

| |||

| DarenSavage |

| ||

Joined: December 2016 Posts: 128 | I already love the look of the new top. I can't wait to see it in its full glory. Well, I can wait since I don't have much of a choice. | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2340 Location: Pueblo West, CO | Yeah, all four of these guitars will be real purty when they're done. I ground down the excess wood on all four guitars yesterday and I'm ready to start routing the channels for the binding/purfling. I ordered the new gold tuners and the abalone purfling for your guitar today. I've already got the EVO gold frets. | ||

| |||

| DarenSavage |

| ||

Joined: December 2016 Posts: 128 |

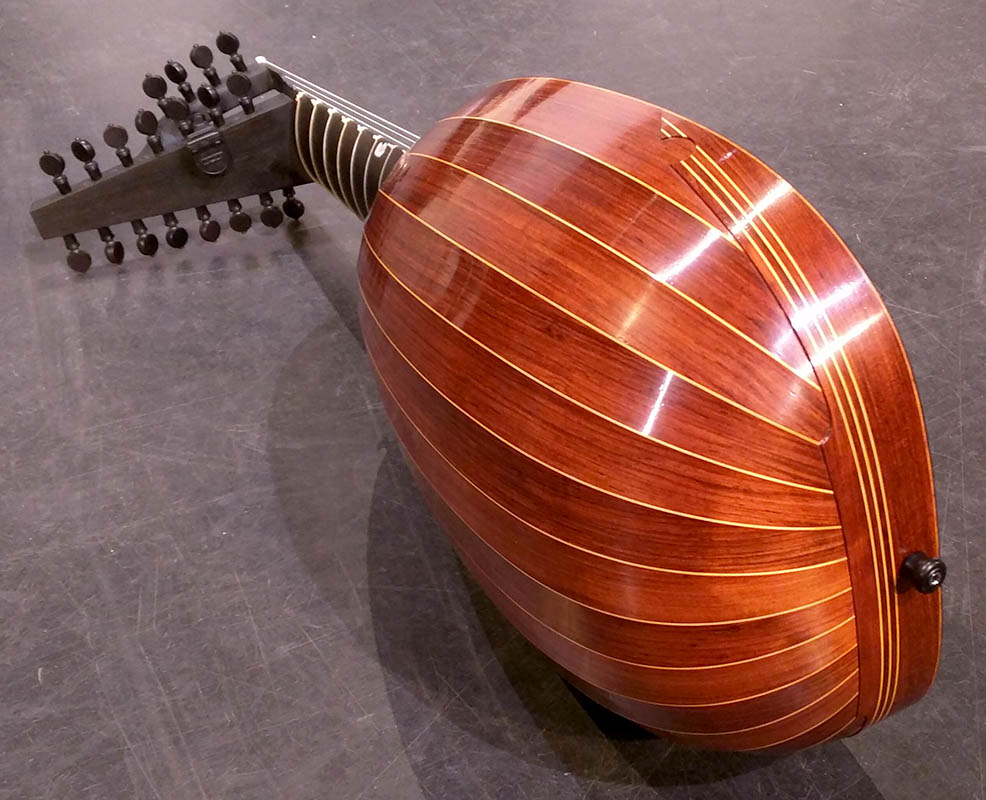

I worked the Baltimore Consort concert this evening. Ronn McFarlane was nice enough to share his lute with me (to look at and photograph, not play - more about Ronn's custom lute here - Ronn kept his lute in his hand the entire concert; even during breaks!). This lute is about a year old and was built by Travis Carey. I told Ronn about my luthier bro, Dan and his plans to built a wooden back Ovation. I also talked to him about Dan using torrified wood, and explained the significance of what it is and why it's used.

I was surprised that the lute is actually sections of flat bent wood rather than a true round back.

More of the back.

All of the Baltimore Consort's string instruments had intricately carved sound holes. As is usually the case in life, I wish I had taken more photos of the other instruments.

The fretting was interesting. It was string that wrapped around the neck. As Ronn explained it, it allowed for minor adjustments in tuning, unlike a guitar with it's permanent frets. Rather than re-tie the string frets, when adjustments are made, they insert little pieces of toothpicks to maintain the necessary tension. Edited by DarenSavage 2017-03-05 8:42 PM | ||

| |||

| Cavalier |

| ||

Joined: March 2013 Posts: 359 Location: undisclosed | Gut frets/strings. Ba ba blacksheep. That is a really unusual lute with ten courses and the bass extension. Around 7 was common but towards the end additional strings were sometimes added. Lute sound holes are called rosettes and featured intricate carving and were the only traditional bling on a lute. Thanks for posting! | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2340 Location: Pueblo West, CO | Thanks for posting these pics, Daren. I find this kind of stuff extremely interesting as the guitar was an outgrowth of the lute. In traditional lutes, the frets, like the strings are gut. When the lute made the transition from the potato bug back, to the pinched waist we associate with modern guitars, the bowl-back persisted and is known as a vaulted-back guitar. Potato-bug bowl mandolins also use flat panels, (staves) as do most vaulted-back guitars. The Alvarez DY92 was a modern vaulted-back guitar. The DY92 started with thicker (1/4" or so) pieces of wood, which were sanded to a round shape on the outside to be aesthetically pleasing. My wood-bowl Ovation(s) will be rounded, but unlike the DY92, I will be bending a compound curve into each stave using steam. The staves will be thickness sanded to near-final thickness (~.080" Anyway, thanks again for sharing this info. Dan | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2340 Location: Pueblo West, CO | Speaking of torrefied wood guitars, I see now that Ibanez is offering a guitar that has, not only torrefied Adirondack spruce top with torrefied Adi X-braces, but also a torrefied East Indian rosewood (EIR) back, torrefied mahogany neck, torrefied EIR fretboard and torrefied EIR bridge. I don't think they're available in the USA yet, but the street price in Europe is €1,599 ($1696) Edited by DanSavage 2017-03-05 9:39 PM | ||

| |||

| DarenSavage |

| ||

Joined: December 2016 Posts: 128 | You're welcome. As Ronn explained, he added the extra bass extensions to simplify his playing by playing them open rather than trying to make complex fingering. Truly high level stuff. | ||

| |||

| DarenSavage |

| ||

Joined: December 2016 Posts: 128 | DanSavage - 2017-03-05 9:35 PM Yah, man. The '35 still amazes me every time I pick it up. If I didn't have it, I might consider the Ibanez. Speaking of torrefied wood guitars, I see now that Ibanez is offering a guitar that has, not only torrefied Adirondack spruce top with torrefied Adi X-braces, but also a torrefied East Indian rosewood (EIR) back, torrefied mahogany neck, torrefied EIR fretboard and torrefied EIR bridge. Edited by DarenSavage 2017-03-06 3:36 AM | ||

| |||

| DarenSavage |

| ||

Joined: December 2016 Posts: 128 | DanSavage - 2017-03-05 9:19 PM You're welcome. Ronn was very nice and accommodating. They rehearsed for a couple of hours before the show. At one point, Ronn saw me admiring his lute from the edge of the stage and brought over to me. That's when we re-positioned in better light for my mini photo shoot. My wood-bowl Ovation(s) will be rounded, but unlike the DY92, I will be bending a compound curve into each stave using steam. The staves will be thickness sanded to near-final thickness (~.080") before bending and joining to maximize the resonance of the bowl. I will be relying on my experience edge-joining/sheeting model airplane fuselages. I'm planning to make the jigs and forms using 3D CAD and laser-cut wood. Anyway, thanks again for sharing this info. Dan How will you achieve the compound curve on the staves? I would think an inside and outside mold would be needed. | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2340 Location: Pueblo West, CO | DarenSavage - 2017-03-06 1:55 AM You're welcome. Ronn was very nice and accommodating. They rehearsed for a couple of hours before the show. At one point, Ronn saw me admiring his lute from the edge of the stage and brought over to me. That's when we re-positioned in better light for my mini photo shoot. How will you achieve the compound curve on the staves? I would think an inside and outside mold would be needed. Very cool of him. I'm planning to design the mold in 3D CAD to make it with egg-crate style interlocking sections. Then, I may sheet it to form a smooth surface and fiberglass it to seal it. Then, I'll steam the stave to soften the wood. Rockler sells a steam bending kit. (See: Rockler Steam Bending Kit) To make the wood conform to the shape of the mold, I'll borrow an old trick from our modeling days and wrap the stave and mold using an Ace bandage and let it dry. I may make two or three molds so that I can speed the bending process up. Each guitar will need 8 mahogany and 7 rosewood staves. Edited by DanSavage 2017-03-06 8:25 AM | ||

| |||

| DetlefMichel |

| ||

Joined: May 2011 Posts: 760 Location: Muenster/Germany | All this sounds terrific complicated and extensive. Wouldn´t it be easier to built a wooden bowl like a dugout canoe, out of one piece (a rosewood stump)?. ..ok.just kidding.. | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2340 Location: Pueblo West, CO | Detlef, Yes, that would be one way to do it. That's how carved balsa hollow nose cones are done. You stick thumbtacks into the outside, then sand until the tips are exposed to get a uniform thickness. But, I like a challenge. | ||

| |||

| Mark in Boise |

| ||

Joined: March 2005 Posts: 12761 Location: Boise, Idaho | If you go back in the archives to 2006 or 07, there was a thread about a wooden roundback that Jeff sent on a tour of OFCers around the country. Several of them were made over in Cambodia or thereabouts. | ||

| |||

| DarenSavage |

| ||

Joined: December 2016 Posts: 128 | Wow, I repaired my first Steinway today. Or, more accurately, I repaired it yesterday (didn't take before photos), and let the glue dry until today. We have a regular guy who services the Steinway before concerts. When he was in here for the Joshua Bell concert, he noticed that a piece of felt had come loose and was interfering with one of the lower E keys. He fixed it with Tite-Bond, but as it's a wood glue, it really needs 24 hours to cure. He only had a few hours before the concert. Sometime after the concert, the glue joint failed and the felt again folded over to interfere with the key. I spoke to him and we identified the problem, and I fixed it.

I searched for something to use as a clamp to hold the felt in place. As it turns out, paint stirring sticks were the perfect width.

A close up of the wood clamping the felt in place. It also worked a mask to keep the glue from dripping on (or into) the keys. I used a narrow screw driver as a palate knife.

All fixed.

Steinway CD 341 is ready for action! Edited by DarenSavage 2017-03-10 10:55 AM | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2340 Location: Pueblo West, CO | Bravissimo! | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2340 Location: Pueblo West, CO | BTW, I've ordered all the new parts for your guitar including the gold tuners, abalone and BW purfling and the binding. The tuners came in a few days ago, the abalone and BW purfling should be in today. So, that means I can start routing the channels this weekend. (Yay!) I didn't want to do any routing until I had the parts in hand so that I could make sure everything fits as it should. Edited by DanSavage 2017-03-10 12:08 PM | ||

| |||

| DarenSavage |

| ||

Joined: December 2016 Posts: 128 | Kewl deal! I understand completely about waiting until you have all the parts. Measure twice and cut once (not the other way around, especially with your favorite brother's custom Ovation). | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2340 Location: Pueblo West, CO | Well, I do if I want to remain his favorite brother... | ||

| |||

| Jonmark Stone |

| ||

Joined: May 2008 Posts: 1564 Location: Indiana | Nice fix Daren. I've used paint stir sticks for many a DIY fix over the years. Perfect width and/or thickness for many head scratchers. | ||

| |||

| Love O Fair |

| ||

Joined: February 2016 Posts: 1881 Location: When?? | Or back scratchers. Good for that, too. Can't remember the last time I actually stirred paint with one (I'm a shaker). | ||

| |||

| Jump to page : < 1 2 3 4 5 6 7 8 > Now viewing page 3 [25 messages per page] |

| Search this forum Printer friendly version E-mail a link to this thread |

| This message board and website is not sponsored or affiliated with Ovation® Guitars in any way. | |

| (Delete all cookies set by this site) | |