|

| ||

| The Ovation Fan Club | ||

| ||

| Random quote: "It's much too late to do anything about rock & roll now ..." - Jerry Garcia / Grateful Dead |

1967 Balladeer Rebuild... 1967 Balladeer Rebuild...

| View previous thread :: View next thread | |

| Member Communities -> Bottom Feeding Luthiery Guild | Message format | |

| DanSavage |

| ||

Joined: June 2012 Posts: 2345 Location: Pueblo West, CO | You got it! Progress continues... | ||

| |||

| SOBeach |

| ||

Joined: April 2010 Posts: 823 Location: sitting at my computer | amosmoses - "stick it down so it's even with the existing label"

Good choice jay! I think being a little off-kilter is very befitting to the BFLG vibe. | ||

| |||

| clrules |

| ||

Joined: September 2005 Posts: 138 Location: Birmingham, AL | This is turning out vewy nice...... can't wait to see the completed guitar! | ||

| |||

| Nancy |

| ||

Joined: December 2014 Posts: 1713 Location: Frozen Tundra of Minnesota | I just Love pouring over every detail Dan, this is all So Fascinating!!! Thank you So Much for sharing! Love the Remade Label too! Very Classy! | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2345 Location: Pueblo West, CO | Thanks, Paul & Nancy. I'm ready to glue the top down, but I've decided to apply a sealer coat to the top before I actually glue it into place. So, right now, I'm running a few tests. I'm going to apply a polyurethane finish instead of the lacquer I used on my 1619, mainly because it won't take as many coats. I tried Varathane. (nyet!) Too soft. Now, I'm testing Min-wax. I tried the water-based and the solvent based. As I suspected, the water-based causes the wood to swell on the finish-side, which introduces a bow into the wood due to the swelling of the wood fibers as it absorbs the water. This effect is not unknown to me, and was totally expected as I used to take advantage of this when sheeting the fuselages on my model airplanes. The solvent-based does not do this, so I'm leaning toward using this. I can explain more when my tests are done and the top is glued into place. Edited by DanSavage 2015-08-25 9:52 PM | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2345 Location: Pueblo West, CO | I still haven't glued the top down. Edited by DanSavage 2015-09-03 11:46 AM | ||

| |||

| jay |

| ||

Joined: January 2009 Posts: 1249 Location: Texas | Tremendous work Dan! Thank you. I wonder how many shiny's were built with the two piece neck (or is it one piece)? I think I have only seen one other, that Mike may have had. Is the bowl going to be neon green, instead of black? My son will really like that! Edited by jay 2015-09-03 12:11 PM | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2345 Location: Pueblo West, CO | You're welcome, Jay. It's a two-piece neck. Sorry to disappoint your son, but the bowl will be black. (I've already ordered the paint) But, if he wants a neon green bowl, or any other wild-looking color, you can always spray it with Plasti Dip. (http://dipheadsunite.com/our-colors/) | ||

| |||

| clrules |

| ||

Joined: September 2005 Posts: 138 Location: Birmingham, AL | Since you're going to make the bowl shiny why did you take the finish off in the first place? Soundclips are required!!!!! Edited by clrules 2015-09-06 2:58 PM | ||

| |||

| jay |

| ||

Joined: January 2009 Posts: 1249 Location: Texas | I think I can answer this...The bowl had 50 years of use on it. It was pretty scratched up ... I scored a RI shiny, but the bowl had been terribly abused. Aside from the excess belt buckle scratches...grooves...it had a 3x4 place on it that appeared to have been burned or melted. The top was in pretty good condition...so I called up Kim and asked how much a bowl would cost. He wanted to see it first, so I sent it in. Didn't need a thing other than the fine craftsmen at the MS to bring her back to NEW condition. I was amazed. I thought that bowl was history. Pretty amazing place...the factory... Anyway...here are some of Dans pics...as you can see... it had seen some use. Hopefully Dan will share with us what he did with the bowl, and what it takes to get that black shiny result.

(s1.JPG) (s2.JPG) Attachments ----------------  s1.JPG (55KB - 0 downloads) s1.JPG (55KB - 0 downloads) s2.JPG (65KB - 0 downloads) s2.JPG (65KB - 0 downloads) | ||

| |||

| DanSavage |

| ||

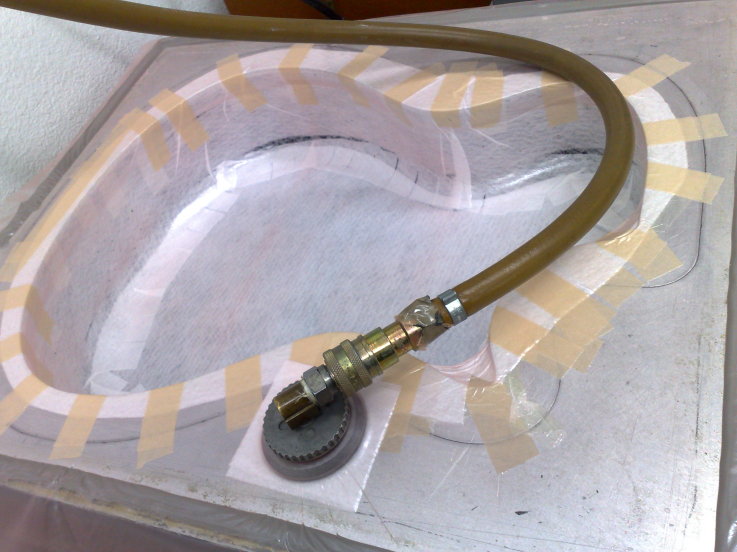

Joined: June 2012 Posts: 2345 Location: Pueblo West, CO | clrules - 2015-09-06 12:50 PM Since you're going to make the bowl shiny why did you take the finish off in the first place? Soundclips are required!!!!! Two reasons. The first, as Jay says, was that there were quite a few scratches. Now, it's true that I could have used glazing putty to fill the scratches and simply scuff up the bowl, then primed and painted. But, the second reason to take it back was to keep the finish from getting too thick and deadening the resonance of the bowl. When it comes to Ovation bowls, thinner is always better. There were basically, four generations of bowls. 1st Gen: Hand-laid woven fiberglass cloth over a male mold. These were vacuum-bagged and scraped to remove as much resin as possible, making the bowl as thin as possible. 2nd Gen: Hand-laid woven fiberglass cloth inside a female mold. These were simple room-temperature lay-ups. 3rd Gen: Polyester resin/roving fiberglass pre-preg (SMC) bowls molded over hot metal molds. 4th Gen: Polyester resin/roving fiberglass pre-preg containing 35% glass spheres (phenolic micro-balloons) Technically, there's a fifth generations bowls, which are hand-laid fiberglass cloth inside a female mold which is both vacuum-bagged and cured in an autoclave. The advantages and disadvantages to the various generation bowls are: 1st: Pluses: Thin, light, strong, flexible. (read: resonant) Minuses: Time-consuming to produce, not resistant to high temperatures. 2nd: Pluses: Fairly thin, strong, fairly flexible. Minuses: Somewhat time-consuming, but lay up can be done without the complicated vacuum-bagging step, not resistant to high temperatures. 3rd: Pluses: Fast to produce, (minutes vs. hours) resistant to high temps. Minuses: Fairly thick, fairly heavy, not very-flexible. 4th: Pluses: Fast to produce, (minutes vs. hours) resistant to high temps, lighter and more resonant than 3rd gen bowls. The 5th gen bowls are a return to the 1st gen technology, but removes some of the time-consuming labor steps. The vacuum-bagging inside the female mold helps squeeze out the excess resin and the high temp of the autoclave cures the resin faster and makes the bowls more resistant to high temperatures. Here's a pic of a guitar body inside a female mold being vacuum bagged.

This bowl is smooth and wrinkle free and is very thin. One day I'll use it to make my own bowl mold. And, it's larger than the 1st gen bowls. Here's a pic of the 1st gen bowl inside the 5th gen bowl. Edited by DanSavage 2015-09-06 6:59 PM | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2345 Location: Pueblo West, CO | amosmoses - 2015-09-06 1:13 PM Hopefully Dan will share with us what he did with the bowl, and what it takes to get that black shiny result Well, the plan is to use Eastwood 2K Aero-Spray catalyzed (2-part) polyurethane gloss black over 2K Aero-Spray flat black epoxy primer. I chose the two-part paint because it's harder and more durable than simple one-part paint. I'll be using the Eastwood 2K Aero-Spray polyurethane gloss clear on the neck and head stock. The neck and head stock are pore-filled and have a seal coat on them. Ditto for the top. I'm going to shoot a one-part clear over the sealer, put the logos on the head stock, do a light wet-sand to level the finish on the neck and then the neck will be ready to shoot the 2K clear. I decided to get the neck and head stock done first because I'll need a handle when doing the top and bowl. Next step after the neck is to prime the bowl. Then, the top will get glued into place and the purfling and binding channels routed and glued down and scraped level. After that, the top will get shot with the 2K clear. Last, the bowl will get shot with the 2K gloss black. Once all of this is done, I'll wet-sand the whole guitar. The last job is to glue the bridge into place. Unlike the dope I used on my 1619, the 2K poly dries hard in 24 hours, so I won't have to wait 3 weeks between the last coat of clear and the start of wet sanding, which speeds up the process tremendously. Another reason I chose the 2K is that the poly can be applied in very thin coats, which will help keep from deadening the resonance of the guitar. Edited by DanSavage 2015-09-06 7:22 PM | ||

| |||

| moody, p.i. |

| ||

Joined: March 2002 Posts: 15679 Location: SoCal | I am really looking forward to playing this guitar when it's finished..... | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2345 Location: Pueblo West, CO | You and me both, brother. I just hope neither of us is disappointed. Working on applying the logos to the head stock. Edited by DanSavage 2015-09-07 11:36 AM | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2345 Location: Pueblo West, CO | The neck has been fully wet-sanded and the logos are on the head stock. Not as perfect as I would have liked. With small details like these logos, the rub-down decals are pretty delicate. This shot really shows the beautiful grain of the Brazilian rosewood head stock veneer. Once the seal coat has fully hardened I'll wet sand the head stock to level the finish in preparation for the final clear coat.

| ||

| |||

| jay |

| ||

Joined: January 2009 Posts: 1249 Location: Texas | Heck, looks perfect to me. Just like the 68. The grain certainly shows up better (which is sweet), it seems, than what it originally looked like and the 68. Of course the logos had pretty much faded out. The crown is certainly unique without the skunk stripe. Getting closer! Fantastic job... Edited by jay 2015-09-07 8:08 PM (68.jpg) (67.jpg) Attachments ----------------  68.jpg (38KB - 0 downloads) 68.jpg (38KB - 0 downloads) 67.jpg (37KB - 0 downloads) 67.jpg (37KB - 0 downloads) | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2345 Location: Pueblo West, CO | Yep. The old headstock logos were pretty much faded out. Here's where we started: | ||

| |||

| clrules |

| ||

Joined: September 2005 Posts: 138 Location: Birmingham, AL | The logos look great and the Braz is definitely very attractive. On the 68 Deluxe I discovered the headstock veneer is walnut instead of rosewood.. It was finished very dark so it wasn't obvious until the finish was removed. The stuff about the bowls is really cool.... Edited by clrules 2015-09-08 9:21 PM | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2345 Location: Pueblo West, CO | Thanks, Paul. Yeah, walnut is a lot easier to finish than RW because it's less oily. But, it's good that I (re)discovered this for when it comes time to glue down the bridge. I created a thread in the General section called, "The History of the Bowl." If you're interested, it contains a lot more details. | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2345 Location: Pueblo West, CO | Finally! Edited by DanSavage 2015-09-16 12:12 AM | ||

| |||

| jay |

| ||

Joined: January 2009 Posts: 1249 Location: Texas | "a while there, it was one step forward, two steps back." I know there are a couple (Dan is thinking "Yeah right Jay, a couple...") of times I drug you back dan...more than two steps, more like a city block. Ok...so Ovation had Black and Brown bowls...It appears they could have been any color... Does anyone know if Ovation did a custom with a bowl any other color than black/brown? | ||

| |||

| Damon67 |

| ||

Joined: December 2006 Posts: 6996 Location: Jet City | Full flames... Professor's got one. | ||

| |||

| moody, p.i. |

| ||

Joined: March 2002 Posts: 15679 Location: SoCal | I've seen green ones and blue ones...... | ||

| |||

| jay |

| ||

Joined: January 2009 Posts: 1249 Location: Texas | Prof (i know you have waited awhile for this request...) Let me see yours! Edited by jay 2015-09-16 3:09 PM | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2345 Location: Pueblo West, CO | amosmoses - 2015-09-16 9:26 AM "a while there, it was one step forward, two steps back." I know there are a couple (Dan is thinking "Yeah right Jay, a couple...") of times I drug you back dan...more than two steps, more like a city block. Well, I was talking about what it took to get the the neck and head stock finished. It's a long and sordid tale. The bottom line is that it's at a point where the finish on the entire neck is at an acceptable level. It's not perfect, but it's a lot better than it was and I think you'll be very happy with it. I applied the first coat of black primer to the bowl. I'll sand it this evening and decide then if it needs a second coat. Edited by DanSavage 2015-09-16 6:04 PM | ||

| |||

| Jump to page : < ... 3 4 5 6 7 8 9 10 11 12 13 > Now viewing page 9 [25 messages per page] |

| Search this forum Printer friendly version E-mail a link to this thread |

| This message board and website is not sponsored or affiliated with Ovation® Guitars in any way. | |

| (Delete all cookies set by this site) | |