|

| ||

| The Ovation Fan Club | ||

| ||

| Random quote: "Believe me when I say that some of the most amazing music in history was made on equipment that's not as good as what you own right now." - Jol Dantzig |

???? 1778T(orrified)... ???? 1778T(orrified)...

| View previous thread :: View next thread | |

| Member Communities -> Bottom Feeding Luthiery Guild | Message format | |

| DanSavage |

| ||

Joined: June 2012 Posts: 2345 Location: Pueblo West, CO | So, I bought this bare bowl off another OFC member sometime last year and stashed it away into the someday pile. It looks like that day has arrived. I guess I'll be doing four guitars at once, not just three. I've been goofing around with moody p.i.'s 1537. I borrowed his 87C for a couple of weeks so I could satisfy my curiosity of how they sound since both of these guitars are rated among Ovation's best by quite a few people. For the most part, I like how both of these guitars sound, but truth be told, my ear has become accustomed to the sound of torrefied wood tops.

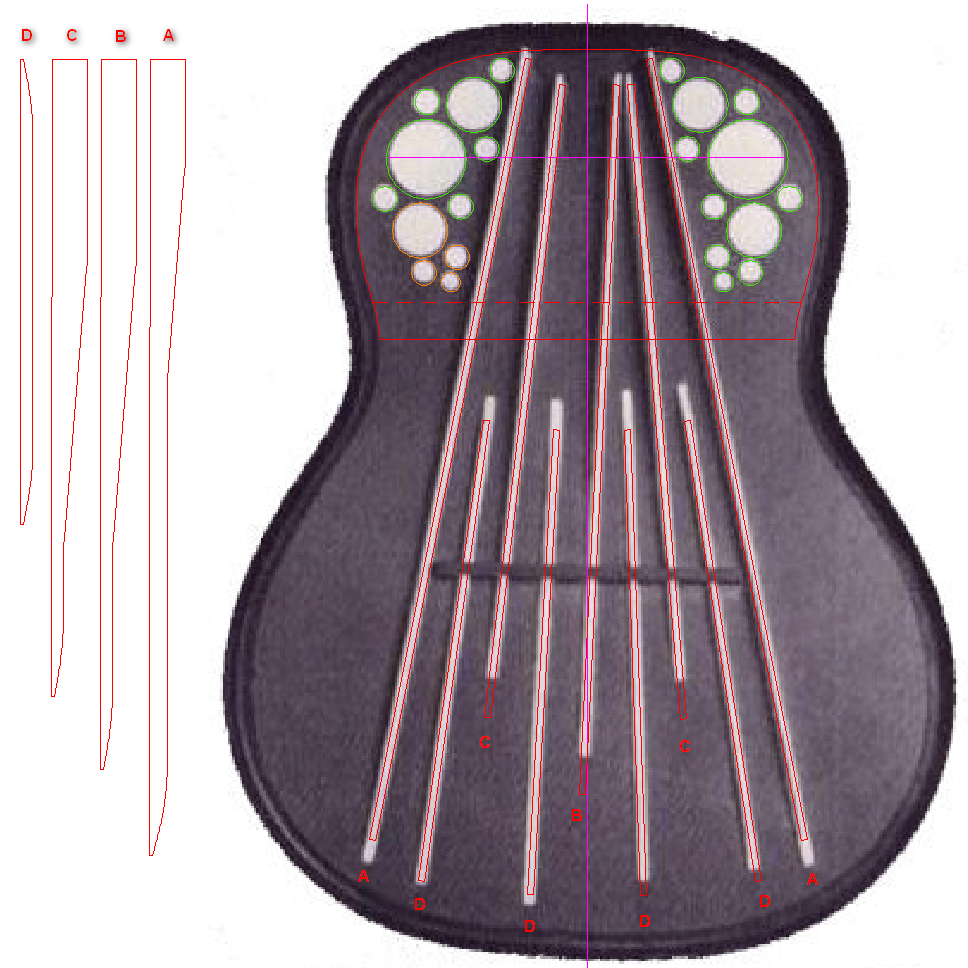

I took a photo of the Adamas braces from the Ovation Tribute site and imported it into CAD. I opened up the back of the 1537 and took some measurements of the braces, then drew them up.

I printed them at full-size, then spray-glued the templates to some 1/8" balsa sheet and cut them out.

Next job is to kit out the braces on all four guitars: 1528, 1612, 1117 and now, the 1778T(orrified). Edited by DanSavage 2017-01-11 1:18 PM | ||

| |||

| DarenSavage |

| ||

Joined: December 2016 Posts: 128 | That's a nice neck. I'm sorry it didn't arrive before I left so I could see it in person. | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2345 Location: Pueblo West, CO | Yeah, it is. I don't have to do anything for this project, but when I get ready to use on the wood-bowl, I'll re-fret it and level the fret board and maybe touch up the finish a little bit. | ||

| |||

| Mark in Boise |

| ||

Joined: March 2005 Posts: 12761 Location: Boise, Idaho | Remember that the original 1537s had a layer of plywood across the upper bout. I don't recall that anyone on this site could figure out why. | ||

| |||

| moody, p.i. |

| ||

Joined: March 2002 Posts: 15679 Location: SoCal | I had to laugh in relief. At first I thought, Dan, that you had pulled the neck on my 1537...... | ||

| |||

| BanjoJ |

| ||

Joined: September 2012 Posts: 815 Location: Thredbo, NSW, Australia | All of your threads are interesting Dan, but this one will be even more so. I've been waiting for you to do an Adamas/Elite style retop - and now you are. Thank you. | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2345 Location: Pueblo West, CO | Mark in Boise - 2017-01-11 11:46 AM Remember that the original 1537s had a layer of plywood across the upper bout. I don't recall that anyone on this site could figure out why. Yep. I noticed that. It looks to me like it's 3-ply 1/32" birch ply. It's got a section that's tapered. This is shown on the plans pic I posted. It's the section of the upper bout outlined in red. The red dashed line shows the tapered section. It looks to me like it's a doubler designed to keep the top from breaking through the small bridges of wood between the sound holes. Because this will be a torrefied wood top, I'm going to try to use a cross-grain piece of torrefied Sitka spruce sanded to either 1/32" or 3/64" thick in place of the non-torrefied birch ply. Well, that is, if the guy I use can sand wood that thin. The birch ply would definitely be stronger, but it also won't resonate like the torrefied spruce. Edited by DanSavage 2017-01-11 5:12 PM | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2345 Location: Pueblo West, CO | moody, p.i. - 2017-01-11 12:57 PM I had to laugh in relief. At first I thought, Dan, that you had pulled the neck on my 1537...... Ha ha! I can see how you might think that and have your heart skip a beat or two... Me: "Hey, Paul. I hope you don't mind but I pulled the neck off your 1537 to see how it would fit my 1778T bowl." Paul: | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2345 Location: Pueblo West, CO | BanjoJ - 2017-01-11 1:26 PM All of your threads are interesting Dan, but this one will be even more so. I've been waiting for you to do an Adamas/Elite style retop - and now you are. Thank you. You're welcome. It was only a matter of time, wasn't it? | ||

| |||

| 2wheeldrummer |

| ||

Joined: February 2014 Posts: 715 Location: moline,illinois | Wow Dan 4 guitars at once,are you going to setup an assembly line lol Excellent diagram of the 1537 bracing I always learn so much from your projects thanks for sharing them with us. | ||

| |||

| DanSavage |

| ||

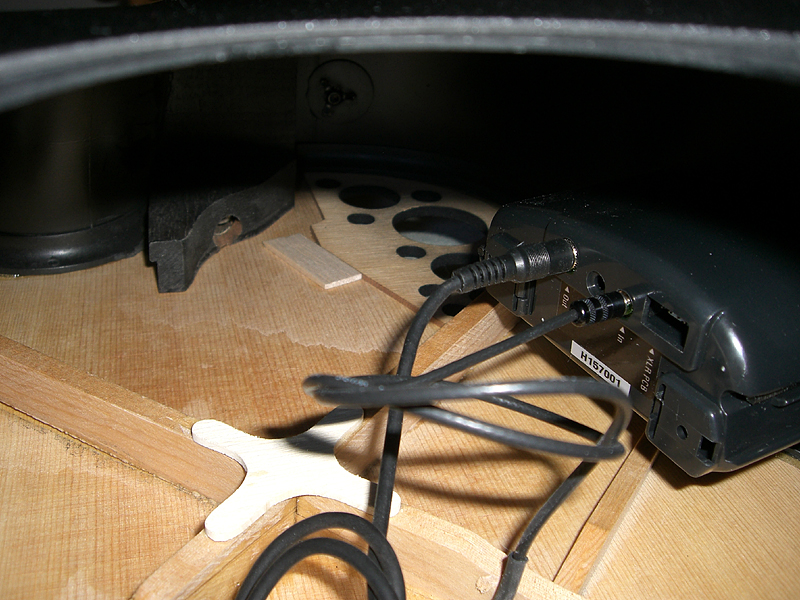

Joined: June 2012 Posts: 2345 Location: Pueblo West, CO | I was able to joint the top in preparation for joining and rough cut the braces.

Referring back to the photo of the upper bout on the inside of the 1537, there is a cross-grain reinforcement. It looks to me like 1/32" birch plywood. I'm not real keen on using birch plywood for this job, first because it's plywood and secondly because it's not torrefied. One of the main reasons why I use torrefied braces on the inside of the torrefied tops is so the braces have the same rate of expansion/contraction with changes in humidity. Using non-torrefied wood would change this. Unlike non-torrefied wood, torrefied wood doesn't really absorb moisture from the air. The second and most important reason is because the braces will of the same 'age' as the top, so they'll both have the same response. IOW, both are already 'broken in'. So, my solution, or at least my first attempt at a solution, was to cut out 1" wide, 1/32" thick slices of the uncut torrefied brace stock. The uncut brace stock is normally quartersawn. I was originally going to use another top, which is quartersawn, sanded down to 1/32" thick for this reinforcement. It occurred to me that quartersawn wood sanded that thin would be prone to cracking and splitting along the grain and would provide almost no reinforcement. By cutting with the grain instead of across it would yield thin wood that is, essentially, flatsawn. IOW, thin, flexible, strong and not prone to splitting. Here's a drawing that shows the differences between quartersawn and flatsawn.

These will get glued edge-to-edge to form a thin sheet, which will get laminated to the underside of the upper bout. Then, I'll drill the sound holes. I'm going to cut all of these to length, then laminate the scrap to a scrap piece of top wood. Once the glue has dried, I'll try drilling holes and see how it works. if the 1/32" reinforcements are too weak, then I'll cut new ones that are a little thicker, then try the drilling test again. Edited by DanSavage 2017-01-17 10:27 AM | ||

| |||

| moody, p.i. |

| ||

Joined: March 2002 Posts: 15679 Location: SoCal | Is that 1st pic my 1537? | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2345 Location: Pueblo West, CO | The pic of the inside of the guitar showing the braces & plywood doubler is your 1537. | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2345 Location: Pueblo West, CO | The outline of the top has been rough cut and the bridge alignment pin holes drilled. This guitar will not be getting the epaulet leaves. Since this is a test piece, it'll be simplified for expediency. Edited by DanSavage 2017-02-16 6:36 PM | ||

| |||

| arumako |

| ||

Joined: October 2012 Posts: 1093 Location: Yokohama, Japan | Hi Dan, your projects look to be coming along immaculately as usual. Thanks for sharing your journey. Love the post with your family X-mas photo. There's no way we'd be able to tell you and your brother apart! Had a question about the "cross-grain reinforcement". Do you see that as a necessity or are you trying to keep the instrument in as original condition as possible? Your torrefied solution is very cool, and I suppose it acts somewhat like a cross-brace. My 1868 has that feature as well, but I wonder as to its necessity...Hmmm | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2345 Location: Pueblo West, CO | Hi Ken, Thanks for the kind words. Yes, the cross-grain reinforcement is necessary. The reason is that the top is quartersawn which means that the grain runs vertically through the sheet, which makes it stiff, but it also split easily along the grain. The epaulet holes are drilled very closely together, with the closest having a 1/8" web of wood. Without some sort of reinforcement, the bridge of wood between the holes would bust out with even the lightest touch. (ugly!) I was originally going to use quartersawn reinforcement, but I thought about it and realized that this, too, would be prone to splitting. So, instead, I sawed these from the brace stock to make flatsawn pieces, which are flexible and split-resistant. I could have used plywood, as was done on the original, but plywood isn't as resonant as solid wood. I also wanted to make the top using all torrefied wood, mainly for the resonance, but also to equalize the rate of expansion/contraction, which wouldn't happen with a torrefied top and non-torrefied plywood. Edited by DanSavage 2017-02-17 11:38 PM | ||

| |||

| Jonmark Stone |

| ||

Joined: May 2008 Posts: 1565 Location: Indiana | I may be mistaken... but didn't they (MS) do some experimentation with using a layer or two of glass cloth and epoxy to reinforce that area at one time? Once again, you're fun to watch, Dan. Thanks for taking the time to document your projects. | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2345 Location: Pueblo West, CO | Hi Jon,

Dan Edited by DanSavage 2017-02-19 6:24 PM | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2345 Location: Pueblo West, CO | Before attempting to drill holes in the top, I decided to mock up a couple of test pieces from the sound holes cut from the other tops. Next job is to mark the locations of the sound holes on the top and drill them out Edited by DanSavage 2017-02-19 6:34 PM | ||

| |||

| tpa |

| ||

Joined: December 2004 Posts: 578 Location: Denmark | Jonmark Stone - 2017-02-19 1:08 AM I may be mistaken... but didn't they (MS) do some experimentation with using a layer or two of glass cloth and epoxy to reinforce that area at one time? Once again, you're fun to watch, Dan. Thanks for taking the time to document your projects. Like this: http://www.ovationfanclub.com/megabbs/forums/thread-view.asp?tid=29... ? Pictures are gone but scroll down to post 7. Other examples have been seen. | ||

| |||

| Jonmark Stone |

| ||

Joined: May 2008 Posts: 1565 Location: Indiana | Thanks tpa. That's what I was remembering. | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2345 Location: Pueblo West, CO | Interesting. I would really liked to have seen photos of the fiberglass lamination. If Beal is reading this I'd like to know the progression of the doublers used. Edited by DanSavage 2017-02-20 8:00 PM | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2345 Location: Pueblo West, CO | I got the sound holes drilled. They aren't as perfect as what the MS could do, but for my purposes they'll work just fine. | ||

| |||

| MWoody |

| ||

Joined: December 2003 Posts: 13996 Location: Upper Left USA | Very encouraging! | ||

| |||

| arumako |

| ||

Joined: October 2012 Posts: 1093 Location: Yokohama, Japan | DanSavage - 2017-02-21 7:26 AM I got the sound holes drilled. They aren't as perfect as what the MS could do, but for my purposes they'll work just fine. Forgive me Mr. Savage, I am afraid I must contend with your definition of "perfect." Jeez, Dan you're too hard on your self! Edited by arumako 2017-02-21 9:56 PM | ||

| |||

| Jump to page : 1 2 3 4 Now viewing page 1 [25 messages per page] |

| Search this forum Printer friendly version E-mail a link to this thread |

| This message board and website is not sponsored or affiliated with Ovation® Guitars in any way. | |

| (Delete all cookies set by this site) | |