|

| ||

| The Ovation Fan Club | ||

| ||

| Random quote: “Music is a moral law. It gives soul to the universe, wings to the mind, flight to the imagination, and charm and gaiety to life and to everything.” -Plato |

1974 1111 Balladeer Rebuild... 1974 1111 Balladeer Rebuild...

| View previous thread :: View next thread | |

| Member Communities -> Bottom Feeding Luthiery Guild | Message format | |

| DanSavage |

| ||

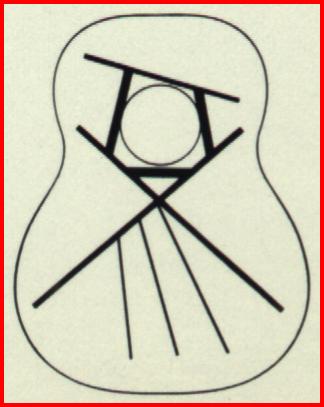

Joined: June 2012 Posts: 2339 Location: Pueblo West, CO | I found this sad 1974 1111-4 Balladeer on eBay a few months ago. It was pretty beat up. The top was cracked in several spots, One of the ears is mangled. And, the neck needs stripping and refinishing. I looked inside the guitar after I got it and found it had an early modified Ovation X-brace pattern, which is very similar to the original X-brace found on the 1960s Balladeers. The only really difference is the addition of the three scalloped tone bars between the lower X-braces. Before stripping all the hardware off the guitar and pulling the top, I decided to string it up to hear what it sounded like. Even though I prefer 80/20s on the Ovation deep bowls all I had on hand was PBs. So, that's what I used. As I expected, the guitar has a rich sound that seems to be unaffected by the numerous cracks in the top. Because of this, I'm going to re-do this brace pattern in torrefied Sitka spruce. (naturally) First order of business was to de-string it and strip all the hardware off it. Next, pull the binding. Now, separate the top from the bowl. Unfortunatley, the original silver foil label is long gone. I may have to forge one using Photoshop and my ALPS printer. :D And, here's what the underside of the top looks like. It's pretty similar to the 1967 Balladeer I did for Jay with a couple of minor changes. First, instead of a 1/16" birch ply star joining the X-braces, it's got a single 1/16" strip that reinforces the notch in the bottom X-brace. And, as I noted previously, it's got the addtional three tone bars. I'm not sure how much these contribute to the sound, so if I were to hazard a guess I'd say these were added to help keep the top from bellying. | ||

| |||

| seesquare |

| ||

Joined: November 2002 Posts: 3651 Location: Pacific Northwest Inland Empire | So, "We're Off to See The Wizard", again. Great news! Probably can't get much more "vanilla" than an early 1111, with a natural top. Let the transformation commence! | ||

| |||

| Mike S. |

| ||

Joined: August 2002 Posts: 665 Location: Ottawa, Ontario, CANADA | Hi, Dan, This " vanilla", model, the Ovation Standard Balladeer in Natural Finish,#1111-4, was the very first Ovation guitar I ever played. The one I played was made way back in 1969, though. Boy, oh, boy, let me tell you what, does seeing this one, even as beat up as it is, ever bring back some great memories. I'll be looking forward to seeing it again, fully restored, by you, of course! The bracing pattern is Ovations' own patent. They called this a,"Modified Fan", I do believe, but you can correct me on this, because you are a luthier, and I am not. Thanks so much for resurrecting this great guitar, because the sound on this guitar is just fantastic. This was BEFORE they invented their pickup! It will be a keeper when your work is completed. Mike S. Ottawa, ON. CANADA Edited by Mike S. 2016-09-25 1:03 AM | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2339 Location: Pueblo West, CO | seesquare - 2016-09-24 7:40 PM So, "We're Off to See The Wizard", again. Great news! Probably can't get much more "vanilla" than an early 1111, with a natural top. Let the transformation commence! Yep. In addition to this one, I'm going to be rebuilding a 1985 1717 at the same time. Since most of the work can be done in tandem, it almost as easy to do two guitars as it is to do one. I'm going to wait to start on the 1717 until I get this one in the same condition and ready to accept the top. | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2339 Location: Pueblo West, CO | Hi Mike, At first I thought this guitar had the Ovation X seen below. But it's got a standard upper transverse brace which is perpendicular to the centerline rather than angled as shown below. Other than that, it's pretty similar. Yeah, if it sounds anything close to how good Jay's Balladeer sounds, I'll be really happy with it. Intead of it using a walnut bridge, I'm going to be using an ebony bridge I got off a 1778 T. I'll also use a bone nut and bridge saddle.

Mike S. - 2016-09-24 10:54 PM Hi, Dan, This " vanilla", model, the Ovation Standard Balladeer in Natural Finish,#1111-4, was the very first Ovation guitar I ever played. The one I played was made way back in 1969, though. Boy, oh, boy, let me tell you what, does seeing this one, even as beat up as it is, ever bring back some great memories. I'll be looking forward to seeing it again, fully restored, by you, of course! The bracing pattern is Ovations' own patent. They called this a,"Modified Fan", I do believe, but you can correct me on this, because you are a luthier, and I am not. Thanks so much for resurrecting this great guitar, because the sound on this guitar is just fantastic. This was BEFORE they invented their pickup! It will be a keeper when your work is completed. Mike S. Ottawa, ON. CANADA | ||

| |||

| Mike S. |

| ||

Joined: August 2002 Posts: 665 Location: Ottawa, Ontario, CANADA | Hi, Dan, Thanks for the kind reply. and new information about your work on these guitars. Wow, two at once, eh? I'm Canada's worst handyman, and I have trouble just changing the strings on my guitars sometimes! I'm looking forward to seeing these two beauties restored to their full guitar glory real soon. Best regards, Mike S. Ottawa, ON. CANADA | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2339 Location: Pueblo West, CO | Hi Mike, Once this was done I was able to slip an old top into place and drop a bridge into place to check the neck alignment. Looks good. No bowl bend will be necessary. (Yay!) I got some new rosettes from the MS which use a light grey background instead of pearloid. To keep the vintage feel of the guitar I used a heat gun to soften the epoxy holding the original rosette. For the most part, it came off pretty cleanly. I'll need to glue the pearloid and use to black paint to touch up the parts that stayed stuck to the top. I'm not sure if I'll use these or the rosette I pulled off the top. It depends on how the original one looks when I get done with it. The pearloid is pretty yellowed and doesn't really show that much 'pearl' any more. I used Ken's (arumako) technique of boiling hot water in a ziplock baggie to soften the epoxy holding the bridge down. I'm very impressed with how well it worked. The bridge came off the top without any damage at all. Even the original routing groove remained intact.

Next job is to remove the finish from the neck and head stock, then start repair the broken ear. Edited by DanSavage 2016-10-03 8:25 PM | ||

| |||

| Love O Fair |

| ||

Joined: February 2016 Posts: 1878 Location: When?? | I may have said this before.. but in addition to the awesome stories you let us witness unfold on your guitar projects, I sometimes enjoy finding a secondary interest in the nifty tools and gadgets seen laying on the bench (okay, so I'm into details), and it all seems to fit the rhyme and reason, though I have to say that the bottle of crabgrass killer has definitely piqued my curiosity on this one. | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2339 Location: Pueblo West, CO | Haha! The crabgrass killer is on my desk/workbench because I was going to use it on the front and back lawn until I found out that what I thought was crabgrass was really kikuyugrass. Unfortunately, normal methods of weed control don't work on kikuyugrass. | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2339 Location: Pueblo West, CO | I sanded the finish off the head stock and neck today.

Next job is to get a small chunk of matching mahogany and repair the broken ear. But, before I start the ear-repair, I'll prepare the top wood and braces for both this guitar and the 1717. Then, while the top wood joint(s) are drying I'll repair the ear. | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2339 Location: Pueblo West, CO | I got the top wood jointed this morning. I'll take this top with me to the sanders Monday morning and get both the 1717 and this one done at the same time.

I was able to clean up the mangled ear and glue a mahogany block to it using OBG. But, when I shaped the block, I found that the color and grain of the patch piece didn't even come close to matching the head stock wood, even with staining. I'm really glad now I used OBG instead of epoxy or CYA as I was able to steam it off. I'll search around to see if I can find a piece that matches a little bit better. I'll also contact the MS to see if JB can grab a piece of scrap off the shop floor, drop it into an envelope and mail it to me. | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2339 Location: Pueblo West, CO | I got the top cut out. Drilled the bridge locating pins (more on that below) and cut the sound hole.

| ||

| |||

| BanjoJ |

| ||

Joined: September 2012 Posts: 813 Location: Thredbo, NSW, Australia | Thanks Dan. I'm loving this and the 1717 story. Keep em coming! | ||

| |||

| moody, p.i. |

| ||

Joined: March 2002 Posts: 15678 Location: SoCal | If you ever played one, you'd love them even more. My Savage 1113 is the one guitar that gets played every day..... | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2339 Location: Pueblo West, CO | Thanks, guys. Braces are glued. I'll pull this out of the gobar deck later this afternoon, then it's time to glue the top to the bowl of both this one and the 1717. | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2339 Location: Pueblo West, CO | Faux foil label. I was able to print it using my Alps printer foil cartridge and it looked great under certain angles, but this looks better under all angles. It's not reflective like real foil, but this is better than no label at all. Top being glued to bowl. Edited by DanSavage 2016-10-12 8:43 PM | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2339 Location: Pueblo West, CO | The glue joint between bowl and top was hard enough to pull the weights off. I'll sand down the excess top material from around the bowl tomorrow once the fret extension glue has had a chance to cure. Once that's done the top will be ready for routing for binding and purfling. Edited by DanSavage 2016-10-13 12:44 PM | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2339 Location: Pueblo West, CO | Binding and purfling channels are routed.

| ||

| |||

| arumako |

| ||

Joined: October 2012 Posts: 1091 Location: Yokohama, Japan | WOW! Coming along nicely...again! Shiny Bowl? | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2339 Location: Pueblo West, CO | Thanks, Ken. Not a shiny bowl. I think they stopped making shiny bowls in the late 1960s. | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2339 Location: Pueblo West, CO | Binding tape pulled up. Binding and purfling scraped level. Top is ready for finishing. But, before I start that I need to turn my attention to the headstock repair. As with the other guitars, I'll finish the neck first, then do the body.

| ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2339 Location: Pueblo West, CO | Time to turn my attention to the broken headstock. Here's what it looked like before I started. After I sanded the finish off, I sanded the broken section flat to prepare it for gluing the patch piece. I bought some mahogany planks locally, and made several attempts, but they didn't come close to matching the grain pattern of the head stock. Thankfully, I followed my first instinct and glued the patches on with OBG, so they were easy to steam off and try again. So, I sent an email to JB at the MS and asked him if he could send some scraps. Here's what I got back. The darker pieces are from the sealer applied to ends of the raw stock that they used to laminate. The actual wood is the same color as the lighter wood on the other side of the laminations. (they're bookmatched) But, when I oriented the grain to match that of the head stock, I had the same problem as the locally-sourced wood -- the grain pattern didn't match. The solution was to turn the piece 90 degrees and use the end-grain, instead. Here's a shot of final patch piece glued into place and sanded to shape. The existing head stock wood is quite a but darker than the patch piece. When it's wet out, you can see the difference in color between the old wood and the new wood. The grain matches pretty good, but it's quite a bit lighter in color. So, the next job was to find a way to stain the patch to get it to match the coloration of the head stock wood when it's wetted out. I used the scrap wood JB sent as test pieces so I could find out what worked best. I ended up using alternating coats of thinned Minwax red oak stain and shellac tinted with burnt sienna and raw umber dry artists pigment to build up the finish to get the best match without overshooting the tint and making it too dark. Here's what the finished patch looks like when it's dry. And, when it's wetted out with naptha to simulate how the clear coat will look. The direction of the grain is slightly off, but it's close enough that it will pass all but the closest inspection. Now that this job is done, it's time to mask off the neck and start applying the clear coat.

Edited by DanSavage 2016-10-25 11:28 AM | ||

| |||

| jay |

| ||

Joined: January 2009 Posts: 1249 Location: Texas | We need "Like" buttons! | ||

| |||

| Old Man Arthur |

| ||

Joined: September 2006 Posts: 10777 Location: Keepin' It Weird in Portland, OR | Really, Really, impressive. | ||

| |||

| BanjoJ |

| ||

Joined: September 2012 Posts: 813 Location: Thredbo, NSW, Australia | jay - 2016-10-26 5:32 AM We need "Like" buttons! +1 I'm loving this one. Very interesting. | ||

| |||

| Jump to page : 1 2 3 Now viewing page 1 [25 messages per page] |

| Search this forum Printer friendly version E-mail a link to this thread |

| This message board and website is not sponsored or affiliated with Ovation® Guitars in any way. | |

| (Delete all cookies set by this site) | |