|

| ||

| The Ovation Fan Club | ||

| ||

| Random quote: "It's much too late to do anything about rock & roll now ..." - Jerry Garcia / Grateful Dead |

1981 1113 Classic... 1981 1113 Classic...

| View previous thread :: View next thread | |

| Member Communities -> Bottom Feeding Luthiery Guild | Message format | |

| DanSavage |

| ||

Joined: June 2012 Posts: 2345 Location: Pueblo West, CO | So, Paul Moody asked me if I'd like to rebuild a 1981 1113 Classic for him that he was buying off eBay. We decided to use torrefied Adirondack top and brace stock instead of the red cedar that was originally used. 1981 was the last year of the woven cloth bowls, so if it needed a bowl bend, I could have done one. Once I got the guitar I checked the neck angle and it looked pretty good, so no bowl bend was necessary. The frets and fingerboard are also in good shape, as is the condition of the finish on the neck and headstock. So, this job will be limited strictly to re-topping. The top is in pretty bad shape with three major splits. The pics below don't really convey the condition of the top. The wood between the splits is severaly cupped. There is no way this top could be repaired. The first order of business is to remove the binding and purfling. Next, the top is separated from the lining using my trusty Xacto chisel. In so doing I discovered the reason for the notches in the lining I've seen on my 1619 and 1617. These are there to allow the brace stock to be 'tucked' into the lining. When braces are tucked normally, the lining is notched and the braces are tapered so they fit between the top wood and the lining. In this case, the copious amounts of epoxy secures the braces to the lining. The only reason braces are tucked is to reduce the number of warranty work that needs to be done. When they aren't tucked, they are more prone to being popped off the top when the guitar is bumped. The problem with tucked braces is they reduce the response of the top. The braces on the new top will not be tucked. Here's the underside of the top sans the braces which are still stuck to the bowl. Paul and I talked about brace patterns and whether I should retain the original double-fan brace pattern or use the original X-brace like what I used on Jay's Balladeer. We decided to use the double-fan braces. But, since the torrefied spruce is stiffer the top and braces will be slightly thinner than the original. The standard thickness was tapered from .140" to .100". For this top, I'll taper it from .120" to .094". The braces will be thinned accordingly. | ||

| |||

| arumako |

| ||

Joined: October 2012 Posts: 1093 Location: Yokohama, Japan | Woo hoo! New Project! That is so interesting how the classical construction is completely different from the steel string cousins. Now we'll get to learn what a torrefied top sounds like on a nylon string-O! Fun, fun, fun! Thanks for sharing Dan! | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2345 Location: Pueblo West, CO | Today's task was to remove the remnants of the soundboard from under the fretboard extension and the glue from the plastic lining in preparation for fitting the top. Ditto for the glue joint between the underside of the top and the top of the neck block. After pulling the top off and seeing the transverse braces that were tucked into the lining, I finally understand why the lining is notched as it is. If you compare the notches in the lining to the brace schematics on Ovation Tribute site, you can see that the notches can be used for the VT-8, VT-10, VT-11, Ovation Fan and Double Fan brace patterns. Here's the massive amounts of glue used to glue the lining to the bowl. Talk about overkill. The next job is to clean up the binding and purfling between the fretboard extension and the top of the neck block. Once that's done, I'll set the body aside and start jointing the top. Edited by DanSavage 2016-05-01 7:02 PM | ||

| |||

| 2wheeldrummer |

| ||

Joined: February 2014 Posts: 715 Location: moline,illinois | Amazing and informative work as always dan,I love to follow your projects and learn so much about what goes on inside the bowl of my favorite guitars. | ||

| |||

| jay |

| ||

Joined: January 2009 Posts: 1249 Location: Texas | Dan, Sweet! This is so fun to watch, not to mention a lesson in each rebuild. Question...quite a few classicals use the long fan approach, with less cross bracing...some provide a V brace at the bottom. Ovation seems to be the only company that used that double fan approach with the additional cross bracing... Does the bowl prevent a long fan appraoch, with less cross bracing...or is this what they went with to accomdate the tucked cross bracing? Or does it matter? ((of course i made up the terms of the bracing, so I hope you catch my drift)) | ||

| |||

| DanSavage |

| ||

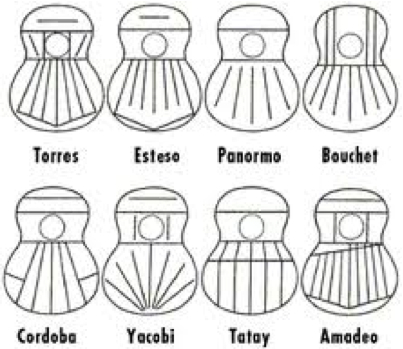

Joined: June 2012 Posts: 2345 Location: Pueblo West, CO | jay - 2016-05-02 8:07 AM Dan, Sweet! This is so fun to watch, not to mention a lesson in each rebuild. Question...quite a few classicals use the long fan approach, with less cross bracing...some provide a V brace at the bottom. Ovation seems to be the only company that used that double fan approach with the additional cross bracing... Does the bowl prevent a long fan appraoch, with less cross bracing...or is this what they went with to accommodate the tucked cross bracing? Or does it matter? ((of course i made up the terms of the bracing, so I hope you catch my drift)) Thanks, Jay. Since I'm only re-topping the guitar it should go pretty quickly. Refinishing the neck is pretty time-consuming, unlike what it takes to refinish the top. WRT to bracing, there are as many different patterns as there are builders, or so it seems. Check out a small selection of the myriad of patterns and these are by no means exhaustive:

By the long fan and bottom V, I assume you mean something like the Torres or Esteso seen below?

IMO, the best sounding tops are thin with minimal braces to impede the resonance. Naturally, there'a balance between strong enough to resist the tension of the strings, but flexible enough so it sounds good. That's what all those designers above tried to do. Here's an interesting article on the evolution of Classical brace patterns. (See: Bracing Styles for Classical Guitars) | ||

| |||

| moody, p.i. |

| ||

Joined: March 2002 Posts: 15679 Location: SoCal | I am, to say the least, excited..... | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2345 Location: Pueblo West, CO | moody, p.i. - 2016-05-02 11:43 AM I am, to say the least, excited..... Do you see any brace patterns above that strike your fancy? LOL! J.K. I'll be duplicating the original double-fan. | ||

| |||

| moody, p.i. |

| ||

Joined: March 2002 Posts: 15679 Location: SoCal | I wouldn't know what to look for. Let's stick with what we have..... | ||

| |||

| jay |

| ||

Joined: January 2009 Posts: 1249 Location: Texas | Go with carbon fiber lattice | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2345 Location: Pueblo West, CO | jay - 2016-05-02 1:03 PM Go with carbon fiber lattice Balsa/CF lattice! The only question then would be what weight of balsa to use? 4-6lb.? 8-12Lb.? Higher? What grain, A, B or C? Too many decisions. I'll just stick with the double-fan made from torrefied red spruce... | ||

| |||

| moody, p.i. |

| ||

Joined: March 2002 Posts: 15679 Location: SoCal | jay - 2016-05-02 1:03 PM Go with carbon fiber lattice Oh so helpful. How come there's never a cop around when you need one...... | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2345 Location: Pueblo West, CO | moody, p.i. - 2016-05-02 4:29 PM Oh so helpful. How come there's never a cop around when you need one...... You just have to know where to look. Did you check the Old Simpson Place? Edited by DanSavage 2016-05-02 7:57 PM | ||

| |||

| jay |

| ||

Joined: January 2009 Posts: 1249 Location: Texas | How come there's never a cop around when you need one...... Hang around the donut shop more often. I might even buy you a cup. | ||

| |||

| moody, p.i. |

| ||

Joined: March 2002 Posts: 15679 Location: SoCal | Sometimes I have to have donuts and coffee just to certify my p.i.-ness....... | ||

| |||

| Geostorm98 |

| ||

Joined: September 2011 Posts: 402 Location: New Hartford CT | The factory was making in excess of 500 guitars per week. What's a little excess glue? Just try and imagine...the human effort that went into mass producing these guitars...we didn't have time saving machines for the most part. It was all done by hand and some of what we may think of as non conforming ended up being exactly what a given musician wanted. I miss those days. It's not comparable to a forensic examination 40 years on. Yeah, the glue was slapped on there! Production! And if it's laying around in the shop we're going to use it for something or other. | ||

| |||

| moody, p.i. |

| ||

Joined: March 2002 Posts: 15679 Location: SoCal | I don't think Dan's observations were being critical. They were just observations. It was a real interesting time in the early 80's. They (you?) were pounding out guitars as fast as they could. They built great products and were never intended to be museum quality pieces. They were tools. Finely made tools. | ||

| |||

| Mark in Boise |

| ||

Joined: March 2005 Posts: 12761 Location: Boise, Idaho | When I got my Folklore it had a buzz that I traced to a broken brace. The hole drilled for the pickup hit a brace. I remember being shocked that this could have happened. After a bit of wood glue, I forgot about it until just now. I've played it for almost 10 years, including today, and these little "defects" caused by a handmade manufacturing process just make it more special. | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2345 Location: Pueblo West, CO | FWIW, all guitars are hand-made, even Yamaha's. Every guitar maker takes shortcuts, even Martin and Taylor. The reason you see cloth patches over the x-brace is to hide the sloppy joint. As Paul says, my comments were observations. No offense intended. In contrast to the copious amounts of glue used for the lining, the lay-up of the bowl is what I, as a fiberglass man, would consider a real work of art. For a hand-laid bowl inside a female mold, there is very sparing use of resin, which is the very definition of good lay-up. When I was scraping the glue off the lining I was pleasantly surprised at how flexible and how easily distorted the bowl was. | ||

| |||

| moody, p.i. |

| ||

Joined: March 2002 Posts: 15679 Location: SoCal | On one of the factory tours, Rick Hall was making that very point, ie, until the mounting ring is put on, the bowl is very pliable. When the ring and then the top go on, it then becomes stiff.... | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2345 Location: Pueblo West, CO | I got a bare hand-laid bowl in the 1619 deal, so I'm able to compare the two. The lining on yours adds a little stiffness, so it's not as flexible as the bare bowl. But, it's still more flexible than either Jay's which has the original molded flanged lining, or my 1617, which has the same lining as this 1113. Edited by DanSavage 2016-05-03 8:10 PM | ||

| |||

| jay |

| ||

Joined: January 2009 Posts: 1249 Location: Texas | George makes a great point And if it's laying around in the shop we're going to use it for something or other. Take for example the 1651-7. Additionally my 67 has a 2 piece neck...why...they needed a neck and probably didn't have the stock on hand. I can count on one hand, the # of 2 piece necks I have seen from the early days. "All guitars are hand made" Well, what about necks and bridges? There is something cool about having a guitar that craftsmen made happen (Including you Dan.). Maybe, back then, all guitar companies made guitars the same way...but it certainly doesnt diminish the cool factor.

| ||

| |||

| Cavalier |

| ||

Joined: March 2013 Posts: 359 Location: undisclosed | Fun stuff Dan. Out of curiosity since the spruce top will make it closer to a 1116 Concert Classic did that one use the double fan too? The brace patterns will inspire hours of reflection alone. At a quick glance I like the 1976 Rodrigeuz Jr. and the Cordoba. Some fall in to the "what were they thinking " catagory but it'd be fun to hear them all. | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2345 Location: Pueblo West, CO | Hi Chris, According to the Ovation Guitars archive, the 1116 used a VT-10 brace pattern. Yes, there are almost as many brace patterns as there are builders of guitars. EDIT: WRT the Rodriguez Jr. brace pattern, he was following the Ramirez pattern, which introduced 'the treble bar,' designed to soften the string bass response and bring out the treble. Interestingly, the Ramirez guitars used scale lengths as long as 668mm, which translated equals 26.299". The 1113 has a scale length of 26.375" Even so, I'm modifying the double-fan brace pattern slightly to account for the torrefied wood I'm using. I've done a little research and it seems that torrefied wood has 10% higher modulus of elasticity. IOW, it's 10% springier than non-torrefied wood. So, to make sure the top and braces are not overly stiff, I'm going to thin them 10%. Also, not tucking the braces will help the top be more resonant. Instead of a taper from .140 to .100 on the top, I'm going to taper it from ~.120 to ~.094. I'm also going to shorten the thickness of the transverse braces from 1/2" to 7/16". I cut the stock today. I also jointed the top wood. I'll make an appointment this week with my sanding guy to thickness sand the top. Once the top is sanded, I'll start kitting the braces. After I have all the braces kitted, I'll trace and cut the top and soundhole, mark the brace locations and get to a-gluin'. Since most of the work is stuff I've already covered I probably won't be taking too many pics of this build, except for stuff I haven't covered before. Edited by DanSavage 2016-05-07 7:06 PM | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2345 Location: Pueblo West, CO | Progress continues. Bridge index pin holes are drilled. Sound hole is cut. New rosette is fitted. I laid out the locations of the braces on the underside of the top. I'm not sure if the fan braces are supposed to be asymmetrical or not, but I followed the locations of the original top.

| ||

| |||

| Jump to page : 1 2 3 4 5 Now viewing page 1 [25 messages per page] |

| Search this forum Printer friendly version E-mail a link to this thread |

| This message board and website is not sponsored or affiliated with Ovation® Guitars in any way. | |

| (Delete all cookies set by this site) | |