|

| ||

| The Ovation Fan Club | ||

| ||

| Random quote: "There are more love songs than anything else. If songs could make you do something we'd all love one another." -Frank Zappa |

The History of the Bowl The History of the Bowl

| View previous thread :: View next thread | |

| Members Forums -> General Posting | Message format | |

| DanSavage |

| ||

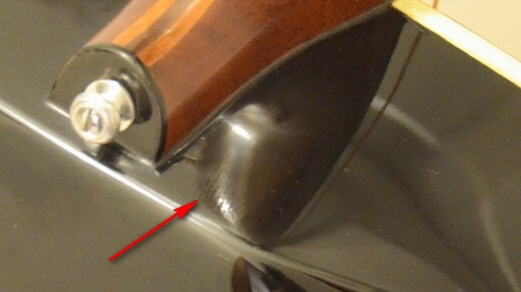

Joined: June 2012 Posts: 2340 Location: Pueblo West, CO | A lot has been written about the revolutionary design of the Ovation guitar. But surprisingly little information is available about the Ovation guitar's most prominent feature --the bowl. Of particular interest in the pics is the extra layers of fiberglass reinforcement applied to the 'tailstock' area. I'm not sure if this was done at the factory or if this was a repair done by a luthier. I would appreciate it if anyone can take a look at this area in their early Ovation to see if theirs has these extra layers of cloth. Photos: 1111 G 552 #1 1984 Factory Tour - SMC bowl molding Edited by DanSavage 2013-01-05 11:44 AM | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2340 Location: Pueblo West, CO | I would like to add that everyone should feel free to add whatever comments/photos to this thread. Another interesting aspect of the photos of G 552 is the relatively crude looking neck block inside the bowl. Strangely, the 5-piece laminated neck appears to be split in the same spot as it would if it used heel-block construction techniques. Edited by DanSavage 2013-01-05 1:54 PM | ||

| |||

| jay |

| ||

Joined: January 2009 Posts: 1249 Location: Texas | Hey Dan Here are some pics from 485 and 1911 I could not tell any difference in the composition or cosmetic makeup of either guitar. When I pulled out my point and shoot and looked at the pictures, I thought there were prehistoric drawings on my bowl, but alas, it appears to be possibly a .20 milkshake spill from 67 | ||

| |||

| moody, p.i. |

| ||

Joined: March 2002 Posts: 15679 Location: SoCal | You know, you can't play 2 old Ovations at the same time. You should send one of them (your choice) to me.... | ||

| |||

| jay |

| ||

Joined: January 2009 Posts: 1249 Location: Texas | How about you come get it. | ||

| |||

| Jonmark Stone |

| ||

Joined: May 2008 Posts: 1564 Location: Indiana | I like this topic... thanks Dan. Even though I experienced this bowl transition real time, I admit I wasn't technically aware of what was really happening. I had an early artist, a pacemaker and a 1613 classic, in that order... through the 70's, all with glass cloth bowls. Light and thin, I would often push the deepest point of the bowl into an indentation, showing the qualities of the construction to newbies at the time. A chip in the outer resin of the classic revealed the white cloth weave beneath. When my '82 Legend arrived from the factory, the SMC bowl was noticeably different... as was my Adamas a year later. No longer able to push in on the back, seemed like solid plastic to me I remember thinking. In truth, I was so taken by the new K-bar necks, the new bowls quickly became an afterthought. I'll be interested in any insights the collective here might have. | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2340 Location: Pueblo West, CO | Hi Jay!

Pretty funny stuff about the vintage milkshake stain. If you're feeling really brave, you could taste it to see for sure...

amosmoses - 2013-01-05 6:48 PM Hey Dan Here are some pics from 485 and 1911 I could not tell any difference in the composition or cosmetic makeup of either guitar. When I pulled out my point and shoot and looked at the pictures, I thought there were prehistoric drawings on my bowl, but alas, it appears to be possibly a .20 milkshake spill from 67 | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2340 Location: Pueblo West, CO | Thanks, Jonmark. The 'blueish' color looks to me like the primer. Where the primer has been sanded through, the natural fiberglass resin shows through as the 'greenish' color. The 'whiteish' color around the neck slot in the top of the body is where the skin of the molded fiberglass resin as been sanded through and is showing the interior of the fiberglass resin/cloth, itself. I have an `82 1655, which was the first year of the SMC bowls and it's noticably thicker and less flexible than my 2078. The later Lyrachord GS bowls also seem vibrate more than the early SMC bowl. (belly rumble) In fact, I've found that the back-door adds structural integrity. Whenever I remove it, the bowl is more flexible than when it's tightly clamped into place. Jonmark Stone - 2013-01-05 9:29 PM I like this topic... thanks Dan. Even though I experienced this bowl transition real time, I admit I wasn't technically aware of what was really happening. I had an early artist, a pacemaker and a 1613 classic, in that order... through the 70's, all with glass cloth bowls. Light and thin, I would often push the deepest point of the bowl into an indentation, showing the qualities of the construction to newbies at the time. A chip in the outer resin of the classic revealed the white cloth weave beneath. When my '82 Legend arrived from the factory, the SMC bowl was noticeably different... as was my Adamas a year later. No longer able to push in on the back, seemed like solid plastic to me I remember thinking. In truth, I was so taken by the new K-bar necks, the new bowls quickly became an afterthought. I'll be interested in any insights the collective here might have. | ||

| |||

| jay |

| ||

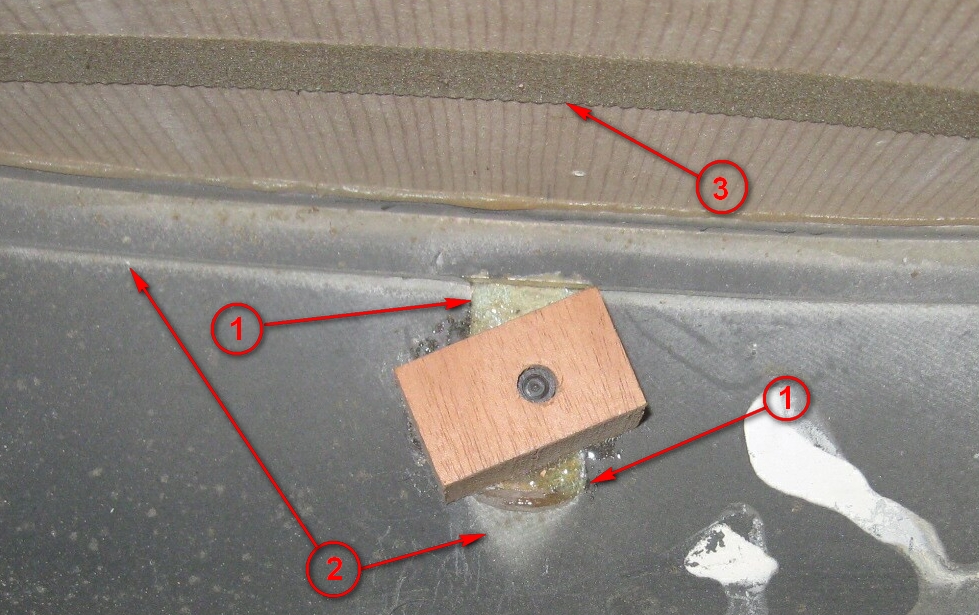

Joined: January 2009 Posts: 1249 Location: Texas | Hey Dan... I am not able to feel any cloth texture in the bowls...it is smooth to the touch. Very nice observation...I hadnt noticed that...you can see the weave, when the light hits it right...especially around the corners. In regards to Pic5 1) I sent this guitar to the MS to have the bowl and soundboard polished. Kim commented to me it was the cleanest 67 that he could remember seeing. The tailpin was missing...so I imagine this is the MS repair. 2) Certainly makes sense 3) I am guessing that it is missing a brace, as you can see from the comparison pic from 495. When I feel it, it isn't foam, it feels like a very thin piece of wood. The top, below the bridge doesnt show any bellying and there are no lacquer cracks. hmmm...puzzled on what to do about this. The strip in 1911 is certainly wider than the brace in 485...and there are no glue globs. "you could taste it to see for sure" Sounds like one of Cheech and Chongs first routines... Edited by jay 2013-01-06 7:06 PM | ||

| |||

| Nick B. |

| ||

Joined: December 2009 Posts: 686 Location: Route 66, just east of the Cadillac Ranch | DanSavage - 2013-01-06 5:06 PM 3) What is that? It almost looks like some sort of sponge foam. Pretty funny stuff about the vintage milkshake stain. If you're feeling really brave, you could taste it to see for sure...

Dan, On the early Balladeers, there was a horizontal strip of fiberglass tape on the underside of the top. Somewhere there's a drawing that shows it, but I can seem to locate it tonight. Here's a photo from an an early Balladeer. I'm not sure what that strip is the picture you posted. Nick (IMAG0237_sm.jpg) Attachments ----------------  IMAG0237_sm.jpg (39KB - 2 downloads) IMAG0237_sm.jpg (39KB - 2 downloads) | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2340 Location: Pueblo West, CO | Hi Jay, Print through is pretty common in the fiberglass industry and it's more of a visual problem than a structural one. It's usually caused by the resin shrinking or too much vacuum being applied to parts being vacuum bagged. It's also more of a problem with darker colors than lighter ones. It could be that during the course of its lifetime, this guitar sat in a stand for a while in a sunny spot. There are ways to minimize it, such as laying down a layer of cloth with a finer weave on the exterior layer, which is what I do. Personally, I wouldn't worry about it. 1) Aha! That makes perfect sense. 3) I looked at the original patent documents and it looks like this may just be the fiberglass reinforcement. It's interesting that 485 has a wood brace but 1911 does not. It's also interesting that 485 looks like it has a lot of excess resin on the back of the sound board while 1911 is almost perfectly clean wood in this area. With instruments this old, it's nearly impossible to determine what kind of life they've had and what's been done to them over the years. It could be that some luthier who was ignorant of the early Ovation construction added the wood brace to 485 somewhere along the line. Personally, if 1911 plays well and isn't bellying, then I wouldn't do anything. If the MS looked at it and gave it a passing grade, then I would leave well enough alone. Thanks again for the pics. Dan amosmoses - 2013-01-06 4:59 PM Hey Dan... I am not able to feel any cloth texture in the bowls...it is smooth to the touch. Very nice observation...I hadnt noticed that...you can see the weave, when the light hits it right...especially around the corners. In regards to Pic5 1) I sent this guitar to the MS to have the bowl and soundboard polished. Kim commented to me it was the cleanest 67 that he could remember seeing. The tailpin was missing...so I imagine this is the MS repair. 2) Certainly makes sense 3) I am guessing that it is missing a brace, as you can see from the comparison pic from 495. When I feel it, it isn't foam, it feels like a very thin piece of wood. The top, below the bridge doesnt show any bellying and there are no lacquer cracks. hmmm...puzzled on what to do about this. The strip in 1911 is certainly wider than the brace in 485...and there are no glue globs. "you could taste it to see for sure" Sounds like one of Cheech and Chongs first routines... | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2340 Location: Pueblo West, CO | Hi Nick, Thanks for the info. I did a search online and found the original patent documents/drawings that describe the reinforcement strip you mention. (See below) Dan

nickbtx - 2013-01-06 7:00 Pm Dan, On the early Balladeers, there was a horizontal strip of fiberglass tape on the underside of the top. Somewhere there's a drawing that shows it, but I can seem to locate it tonight. Here's a photo from an an early Balladeer. I'm not sure what that strip is the picture you posted. Nick Edited by DanSavage 2013-01-07 9:36 AM | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2340 Location: Pueblo West, CO | Another example of an early Ovation came up for sale on eBay. (Thanks, Jay!) | ||

| |||

| DanSavage |

| ||

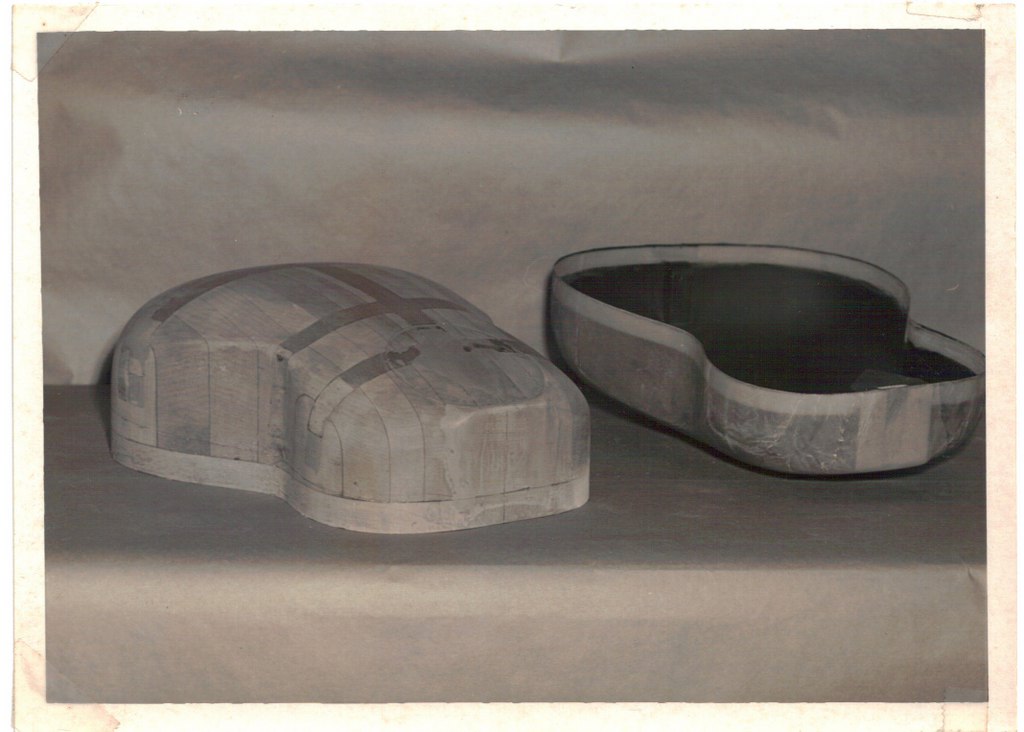

Joined: June 2012 Posts: 2340 Location: Pueblo West, CO | TJR recently sent me some pics I thought were very interesting, so I thought I'd share. If you read 'The Book', the process for making laying up these bowls is described on PP. 26. While the 2x2 twill weave cloth can easily form over this kind of shape, the clear plastic sheet is used for for molding over a compound curved back cannot fully conform to the shape. It folds over and wrinkles when the vacuum is applied. This produces the characteristic ridges and valleys we can see in the photos along the sides and radius to the back. Once the resin has cured, these need to be sanded smooth, which we can see in this bowl. TJR relates that this bowl is noticably smaller than the modern bowl he sent me and would fit inside the modern bowl with room to spare.

In this next photo we see a laminated wooden plug. This is from a very early development period. We can tell this because of the slab sides and lack of radius between the back and the sides along the upper and lower bouts. It also has more of a dreadnaught shape rather than the pinched-waist OM-style used by virtually all Ovation guitars. I suspect this was from a mid-step engineering test between the flat-backed fiberglass design and the fully-radiused design seen in the pics above. This type of construction is fairly normal for mold-making. Being solid wood, I'll bet it weighs a ton.

Edited by DanSavage 2014-05-14 8:56 PM | ||

| |||

| marenostrum |

| ||

Joined: August 2007 Posts: 1008 Location: Tuscany, Italy | Thank you Dan.... | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2340 Location: Pueblo West, CO | You're welcome. | ||

| |||

| arumako |

| ||

Joined: October 2012 Posts: 1093 Location: Yokohama, Japan | DanSavage - 2013-01-05 3:48 AM I would like to add that everyone should feel free to add whatever comments/photos to this thread. This is really interesting stuff... thanks for the in-depth history lesson. I never realized Lyrachord came so late in Ovation lore. Edited by arumako 2014-05-16 5:34 AM | ||

| |||

| DanSavage |

| ||

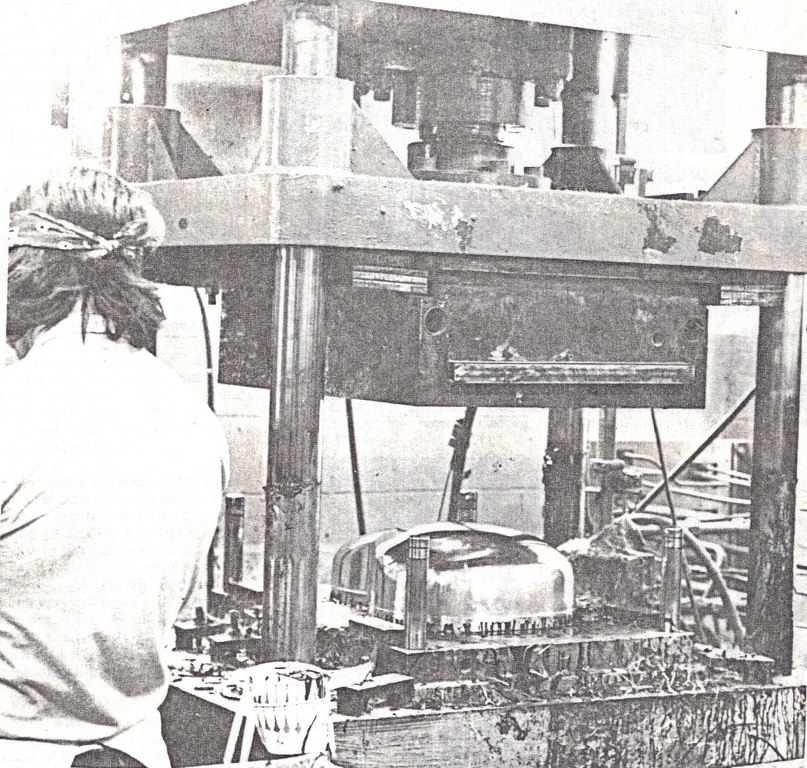

Joined: June 2012 Posts: 2340 Location: Pueblo West, CO | You're welcome. I'm glad you're enjoying it. I've got some really interesting pics coming up. Keep in mind that the whole 'Lyrachord' moniker is strictly a term Ovation marketing applied to the composite bowl. There were several processes used throughout the years to mold the bowl. Every single one was called 'Lyrachord'. As can be seen, there's really nothing special about the process or the components. In the early days, it was off the shelf fiberglass borrowed from Charlie's helicopter business. The first bowls were molded vacuum-bagged over male molds, but that process is very labor-intensive. To save time, they went to female molds, which didn't require as much labor. Finally, they wen to SMC. SMC is an industrial composite used to mold Corvette bodies and other things. It allowed Ovation to produce bowls more quickly, which reduced the cost of each bowl even more and thus, increased the profit margin through reduced labor cost. Finally, they went back to hand-laid bowls in female molds, again, but only for Adamas and custom guitars. To get the quality of the 1st gen bowls, they utilized vacuum and a membrane inside and autoclave. This produces bowls with the surface perfection and reduced production costs of SMC, but the thinness and responsiveness of the 1st gen cloth bowls. | ||

| |||

| sycamore |

| ||

Joined: March 2007 Posts: 698 Location: Cork, Ireland | Jonmark Stone - 2013-01-06 5:29 AM "...Light and thin, I would often ...". Are you still light and thin?? Interestign topic anyway! | ||

| |||

| MWoody |

| ||

Joined: December 2003 Posts: 13996 Location: Upper Left USA | I love when people take things apart and put them back right in front of you! Good stuff! | ||

| |||

| sycamore |

| ||

Joined: March 2007 Posts: 698 Location: Cork, Ireland | Also interesting how the patent shown above gives a detailed description of a truss rod. Apparently that was patented in 1923: http://worldwide.espacenet.com/publicationDetails/biblio?CC=US&NR=1... | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2340 Location: Pueblo West, CO | MWoody - 2014-05-16 7:57 AM I love when people take things apart and put them back right in front of you! Good stuff! You'll really enjoy the pics I just got. I'll post them tonight along with a description of what you're seeing. | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2340 Location: Pueblo West, CO | sycamore - 2014-05-16 8:00 AM Also interesting how the patent shown above gives a detailed description of a truss rod. Apparently that was patented in 1923: http://worldwide.espacenet.com/publicationDetails/biblio?CC=US&NR=1... I could see the document earlier, but I wanted to thank you for posting the link. The curvature of the truss rod almost makes me think that tightening it would cause the neck to bow upward. | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2340 Location: Pueblo West, CO | Here's a couple of pics of the newest generation cloth bowl. This is the same bowl I used to mold the patch on my 1619-4 Repair thread in the BFLG forum. Here's a couple more pics of the 1st gen cloth bowl.

Here's a pic of the 1st gen bowl inside the newest gen cloth bowl. As you can see, they've gotten larger over time. This is not caused by shrinkage. Usually when epoxy resin shrinks, it just makes the parts thinner, not smaller.

In contrast, a female mold can be made to net depth because the part can be trimmed to the top edge of the mold. The sharp angle of the neck block shows us this is a very early bowl, probably 1965-1966.

In contrast, here is a pic of the two-part mold used to produce the SMC bowls. Welcome to the industrial age!

Here's another 1st gen top. This one is a 3-piece spruce top, circa 1966. How do we know it's from 1966? Why, because it's been dated! Although the X braces and popcicle braces have been scalloped, and the center joint reinforced (with birch plywood, no less!) the glue joints between the X braces and the soundhole strips are pretty sloppy. Also seen is the fiberglass reinforcement strip across the lower bout mentioned in the patent documents above. Edited by DanSavage 2014-05-16 8:29 PM | ||

| |||

| jay |

| ||

Joined: January 2009 Posts: 1249 Location: Texas | Dan...just curious...where did you get the tops? And do we have any idea how many of those wooden molds they used in production in the 60's...and you wonder what happened to all of them... | ||

| |||

| Jump to page : 1 2 3 Now viewing page 1 [25 messages per page] |

| Search this forum Printer friendly version E-mail a link to this thread |

| This message board and website is not sponsored or affiliated with Ovation® Guitars in any way. | |

| (Delete all cookies set by this site) | |