|

| ||

| The Ovation Fan Club | ||

| ||

| Random quote: "Jazz... isn't that just a series of mistakes disguised as musical composition?” - David St. Hubbins of Spinal Tap |

UK II nut UK II nut

| View previous thread :: View next thread | |

| Members Forums -> Ovation Electric Guitars | Message format | |

| Mark in Boise |

| ||

Joined: March 2005 Posts: 12761 Location: Boise, Idaho | For some reason someone replaced the nut on the UK2, which should be brass, with a plastic nut. My Viper, however, has a brass one. I'd swap them except the Viper neck is narrower. First, does the brass nut make much difference and, if so, how? Second, is the one for the UK2 comparable to any other guitar with a 1 11/16 nut? In other words, can I use whatever I can find if it's the right length, or do I have to worry about string spacing, fretboard radius and other issues? | ||

| |||

| Mr. Ovation |

| ||

Joined: December 2001 Posts: 7243 Location: The Great Pacific Northwest | I don't think it's compatible. I'll check tomorrow but I think I have an extra UKII nut. Email me and I'll get the details and such to send it.. mileskb at aol dot com As far as the difference, the brass just adds to the whole sustain thing. On many guitars it makes things brighter, but on the UKII it just makes it right. As a side note, I have an aluminum nut I made years ago for my Viper. That really changed the sound in a nice way. Added a richness and clarity without doing too bright. | ||

| |||

| numbfingers |

| ||

Joined: January 2006 Posts: 1131 Location: NW Washington State | If Miles can't find his nut, I have a brass Allparts nut that might work. The slots are precut but might not match the UKII radius. Bought it for a UKII neck but haven't installed it. Could take a long time to find it, because my nut is small and mixed in with my larger parts. Long long ago I took my Viper to Dan Torres' shop in San Carlos to have a brass nut installed on my Viper. Didn't make a huge difference, but they did scratch the headstock, apparently while filing the nut slots, which were cut so that the string spacing was uneven. <RANT> Only later did I figure out that Torres is a hack butcher who became well known only because his shop was near the offices of Guitar Player magazine. </RANT> Edited by numbfingers 2014-02-12 9:00 PM | ||

| |||

| Mark in Boise |

| ||

Joined: March 2005 Posts: 12761 Location: Boise, Idaho | The Viper is only 1 5/8. I didn't notice much difference until I was playing hammer ons and pulloffs on open chords and couldn't seem to get my fingers from muffling the next string. I'm not much better with the UK II, but it's noticeably wider at the nut end. I like the Viper twang, which is probably enhanced by the brass nut and wondered what it should do to the UKII. The Viper looks like it has some repair where the headstock starts, so maybe that's why the nut was replaced. The UKII nut has glue slopped around it. I'm doing a very cheap restoration project. It will also be a good excuse to change the strings. | ||

| |||

| Damon67 |

| ||

Joined: December 2006 Posts: 6996 Location: Jet City | Mark, have you tried calling Mother? I swear they put a brand new one on when they fixed my neck. | ||

| |||

| Mark in Boise |

| ||

Joined: March 2005 Posts: 12761 Location: Boise, Idaho | I emailed Miles. If he doesn't have one, I'll call the Mothership. This is one of my many winter projects that I never started and winter is almost over. | ||

| |||

| Beal |

| ||

Joined: January 2002 Posts: 14127 Location: 6 String Ranch | I got one if all else fails | ||

| |||

| Mark in Boise |

| ||

Joined: March 2005 Posts: 12761 Location: Boise, Idaho | Thanks guys. I finally got ahold of John Budny. His email must have changed since the last time I used it or I was screwing something up. He's going to check the parts bin. If he can't find one, I'll get back to Miles and Beal. | ||

| |||

| Mr. Ovation |

| ||

Joined: December 2001 Posts: 7243 Location: The Great Pacific Northwest | The one I have appears to be "unfinished" in that it's the right dimensions, but not polished down and contoured like the ones on the guitars. Maybe Beal or someone remembers how the build went because the nut I have was obviously installed at some point. Did they install the nuts THEN shape them? Seems a little counter intuitive but I'm sure if they did it, it had a reason... | ||

| |||

| TJR |

| ||

Joined: July 2002 Posts: 288 Location: Maine | Sounds like a great project. Would like to see the finished product . If all others leads fall through , I've got several, some still wrapped in paper I'll verify the width TJR. | ||

| |||

| Mark in Boise |

| ||

Joined: March 2005 Posts: 12761 Location: Boise, Idaho | I guess I better take some "before" pictures, in case I ever get to the "after" part. What we really need to find are the original tone and volume knobs. That would be a project that even I could do. Edited by Mark in Boise 2014-02-27 12:58 PM | ||

| |||

| danomyte |

| ||

Joined: January 2014 Posts: 402 Location: Taxed To Death State | I don't even think the nuts are solid brass. | ||

| |||

| TJR |

| ||

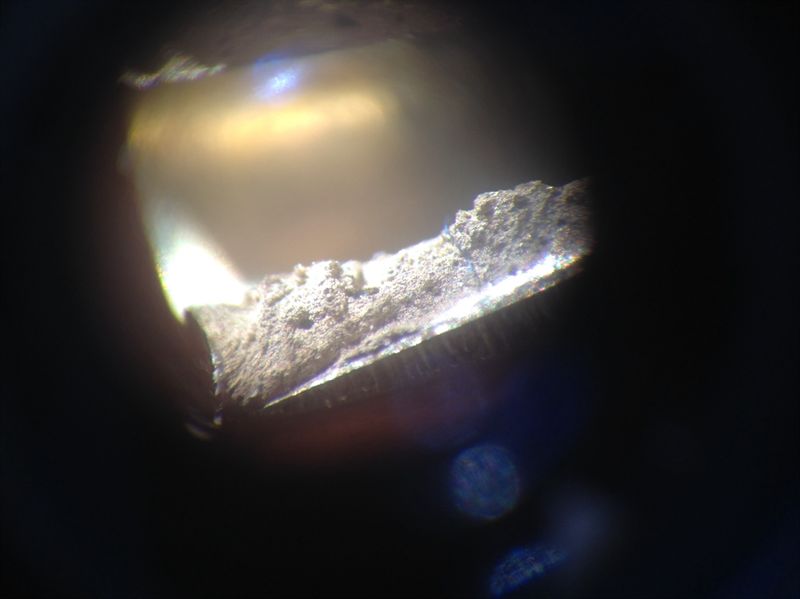

Joined: July 2002 Posts: 288 Location: Maine | The ones I have are 1-11/16" wide As for solid brass , they feel heavy enough to be so I cut one in half It appears to be gold plated over cast brass I'm away from home so it's not so easy to post pics right now I haven't figured out how to do it on my mobile device | ||

| |||

| MWoody |

| ||

Joined: December 2003 Posts: 13996 Location: Upper Left USA | Edited by MWoody 2014-03-01 11:09 AM | ||

| |||

| TJR |

| ||

Joined: July 2002 Posts: 288 Location: Maine | A BIG thanks to MWoody for posting those pics up for me !! | ||

| |||

| MWoody |

| ||

Joined: December 2003 Posts: 13996 Location: Upper Left USA | Ain't no big thing! On cast metal: My understanding of the "Die Cast" process is that the molten metal is injected and the metal cools from the outside in. Since the injected metal is hot and expanding this forces more metal into the mold than a simple pour. You end up with compressed metal (different grain structure) around the outside than in the center and it can add to the way the piece handles energy. Is this all theory or proven mojo? | ||

| |||

| TJR |

| ||

Joined: July 2002 Posts: 288 Location: Maine | If I had to guess. Id say they're from Schaller Probably same process used to make the tuner buttons | ||

| |||

| danomyte |

| ||

Joined: January 2014 Posts: 402 Location: Taxed To Death State | Ahhh that would explain why I saw silver on the bottom of mine when I sanded it lightly to make the glue stick better. They chrome plate them before applying the gold finish. | ||

| |||

| Mark in Boise |

| ||

Joined: March 2005 Posts: 12761 Location: Boise, Idaho | I think that's the right width, so quit cutting them up! I haven't heard back from John Budny yet about what he found in the parts bin. | ||

| |||

| Mark in Boise |

| ||

Joined: March 2005 Posts: 12761 Location: Boise, Idaho | Just received the new nut from John in the mail. It looks just like the one in the pictures above. Now I'll have to take the before and after pictures and maybe try to polish the tarnished one on my Viper. Thanks, John and all the rest of you. | ||

| |||

| Jump to page : 1 Now viewing page 1 [25 messages per page] |

| Search this forum Printer friendly version E-mail a link to this thread |

| This message board and website is not sponsored or affiliated with Ovation® Guitars in any way. | |

| (Delete all cookies set by this site) | |