|

| ||

| The Ovation Fan Club | ||

| ||

| Random quote: "It's much too late to do anything about rock & roll now ..." - Jerry Garcia / Grateful Dead |

Replacing neck binding on a Deacon Replacing neck binding on a Deacon

| View previous thread :: View next thread | |

| Member Communities -> Bottom Feeding Luthiery Guild | Message format | |

| FlySig |

| ||

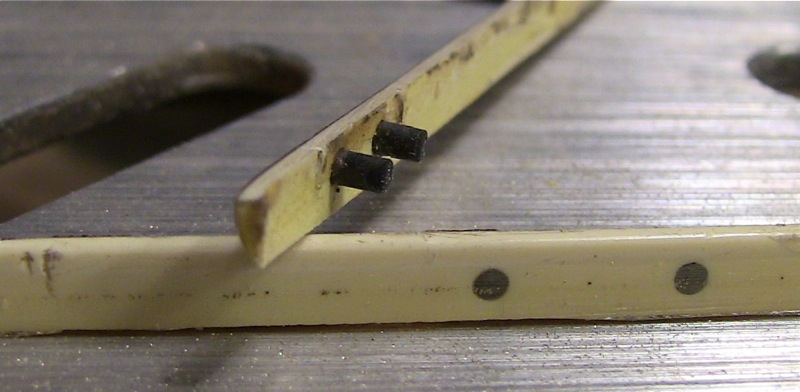

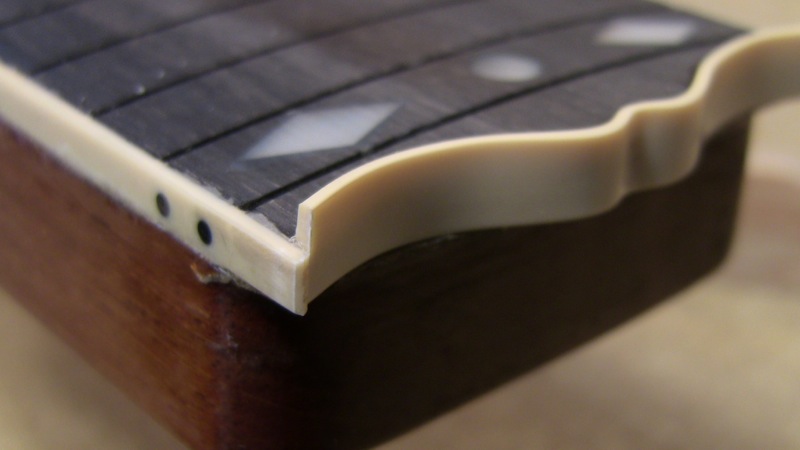

Joined: October 2005 Posts: 4079 Location: Utah | This project turned out to be a lot more work, worry, and fiddling than I expected. This is a mid 1970's Deacon with well worn frets (not the originals) and binding which was shrunken, cracked, discolored, coming loose in spots, and had some bits missing. What the heck, might as well put some new binding on while refretting. This is not a job for the faint of heart, and difficult to get to match the original. Sending it back to the Mother Ship would be a smarter option on a prized guitar. The original binding is .040" thick ABS plastic, creme colored. The glue I used is Sig-Ment, which is a plastic model glue available at local hobby shops. If you use a different material you may need to use a different kind of glue. Acetone will dissolve ABS easily. Some people use it to make their own glue by mixing it with shavings of the binding. Acetone works well to touch up corners where the bindings meet or to fix a loose spot after gluing. This first photo shows the condition of the original binding. The top edge of the binding was well worn, leaving no shelf for the frets, thus the last frets to be installed were shortened to just the edge of the wood.  To remove the old binding, carefully score the finish at the joint between the binding and the neck. The original finish is sprayed over the binding, so if you don't score it really well with a sharp blade it will not break clean. Once scored, the binding can be pulled off easily. Get hold of it and pull it away starting at the fretboard edge. (You'll have to pull all the frets first). The side dots were originally installed at the factory after the binding was installed by drilling through the binding into the wood, then gluing in the dot material. In this photo you can see the side dots still sticking out the back side of the old binding. Also note how much the profile of the binding was damaged by use and most likely refretting.  Once the binding is pulled, clean off all the glue from the wood. Acetone will dissolve the original glue. I carefully and gently used a chisel to by hand scrape away some of the larger globs of glue. Here is an edge after the glue was removed. One of the drill holes from an original side dot is visible. Also note a chip-out of the gloss coat by the fret slot. That kind of damage is difficult to get really smooth once the new binding is installed, and is why careful scoring of the finish before removing the original binding is key.  One complication is down at the heal of the neck where the binding channel is not as deep as the binding. Getting a smooth transition from the gloss coating of the neck to the new binding is a big challenge all along the neck, especially here. This photo is after the new binding was installed along that edge.  | ||

| |||

| FlySig |

| ||

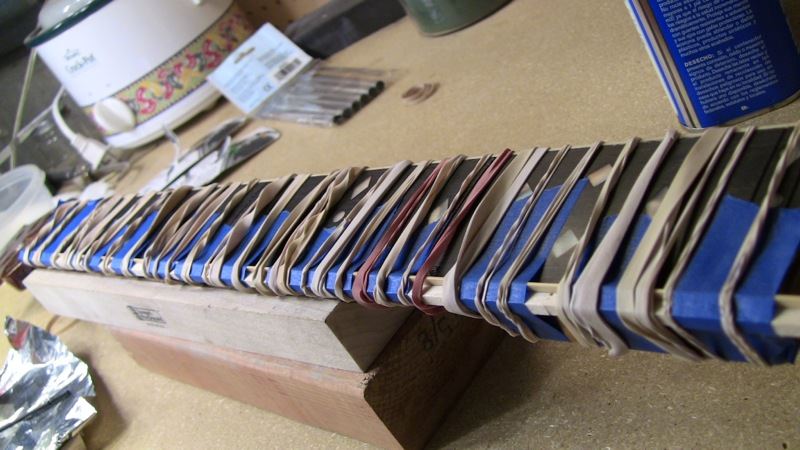

Joined: October 2005 Posts: 4079 Location: Utah | Installing the new binding is not terribly difficult, just a bit fiddling to get it right and do it quickly. But before you install the new binding you will want to sand the fretboard. See the thread on refretting for details. The treble side binding has no dots and was installed in one frantic glue operation. By doing it this way I was able to get the entire length correctly positioned. But the glue was not strong in a few spots which required Acetone be wicked into the glue joint to reactivate the glue. Overall I don't recommend attempting to glue it all in one go. Leave a little extra length at both ends. It is very easy to trim after it is glued. Because the new binding is taller than the top of the fretboard, taping or rubber banding it would tend to tilt it. So I used a length of square wood to press down along the glue joint to keep it in place. Lots of rubber bands! StewMac sells a length of rubber band material for binding which would be a big help compared to what I did. Our grocery store sells large rubber bands for kitchen garbage cans which are cheaper than the StewMac but shorter.  After letting the glue dry overnight this is how it looks. There is squeeze-out of melted plastic but it cleans up very easily with a scraper or sandpaper. Here you can see how the binding is taller than the fretboard and there is some extra length hanging into the nut area. Yeah, you'll have to remove the nut and probably make a new one to match the new frets.  Squeeze-out into the fret slots easily comes out using a fret slot cleaning tool. Glue on top of the fretboard is easily removed when sanding the new binding flush with the top of the fretboard.  Edited by FlySig 2014-10-03 9:02 PM | ||

| |||

| FlySig |

| ||

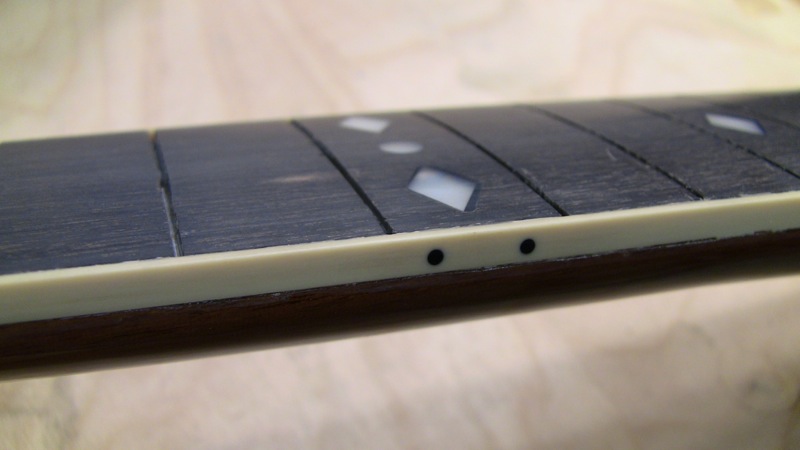

Joined: October 2005 Posts: 4079 Location: Utah | Installing side dots is easy once you figure out a method. I made a fence for my dremel drill press. Each dot is drilled the exact same distance from the edge of the binding. The location is carefully marked onto the binding by using the existing holes in the side of the fretboard. Use the smallest diameter side dot rod you can buy. Put the rod into the hole, nip it off with the fret cutters (or any good flush cutting tool). Then apply a small drop of thin super glue to both sides. Once all the dots are glued in, trim off the excess glue and dot material. There are several methods. I found the best for me was to put a fret leveling file in a vise then pull the binding across it. StewMac has some videos. To glue the bass side binding on I decided to glue in segments, about 4" long each. That's one long piece of binding, glued 4" at a time. Not multiple short pieces of binding! First I placed the old nut as a positioner for the binding. On this side because of measuring for the side dots I couldn't have excess length at the nut end.  This shows one section already glued on, taped, and banded. The next section has glue already applied. The square stick is sitting on the fretboard ready to be put in place for taping.  Here's the whole length taped and bound.  Once the glue is dried, trim off the excess height using fret cutters or any good flush cutting tool. Then use a file to get close to the wood, being careful not to damage the wood. Use a radius block (ideal) or a plain flat sanding block with 320 grit sand paper to get the binding right down to the wood. Finally, use finer sandpaper to get a smooth top surface on the binding. Clean up any minor scratches in the fretboard.  Along the bottom edge of this new binding you can see the uneven edge of the clear coat. It can be filled in with thin super glue. I wiped it down several times with acetone to smooth out the super glue. It worked ok but not great. Simulating playing with my left hand, it feels pretty smooth. I want to work more on these transitions from the old clear coat to the new binding.  Edited by FlySig 2014-10-03 9:38 PM | ||

| |||

| FlySig |

| ||

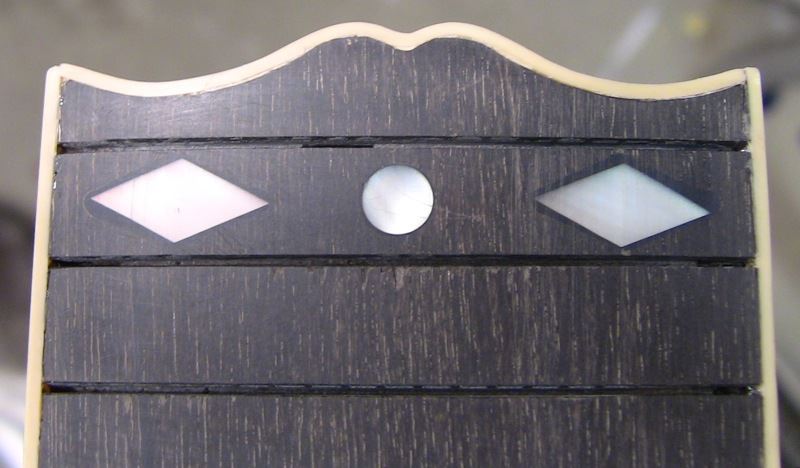

Joined: October 2005 Posts: 4079 Location: Utah | Replicating the mustache at the end of the fretboard was a bit of a frustration. I made a simple jig to bend the molding. Dan Savage made a much better jig which held itself in alignment. Still, this one worked even if it caused a few 4 letter words! I traced the shape of the end of the fretboard, and carefully cut it using a scroll saw. It took a couple of tries to get a good smooth shape which matched properly. Then a heat gun was used to soften the binding and pressed between the two halves of the jig. A heated metal press would be far superior! This is the old mustache and the jig.  To glue the new piece on, I used one half of the jig and stood the neck up on end to apply pressure. It worked great. The workspace is my wife's jewelry bench with a ventilated hood. These glues and solvents are hazardous, so wear a respirator and ventilate the area.   The extra height of the binding is nipped off and then sanded down flush. Acetone can be wicked into the joints between the pieces to fuse them together.   | ||

| |||

| FlySig |

| ||

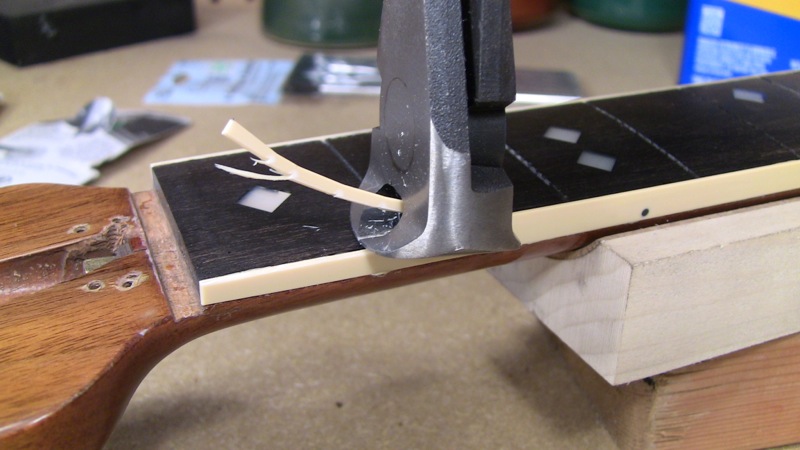

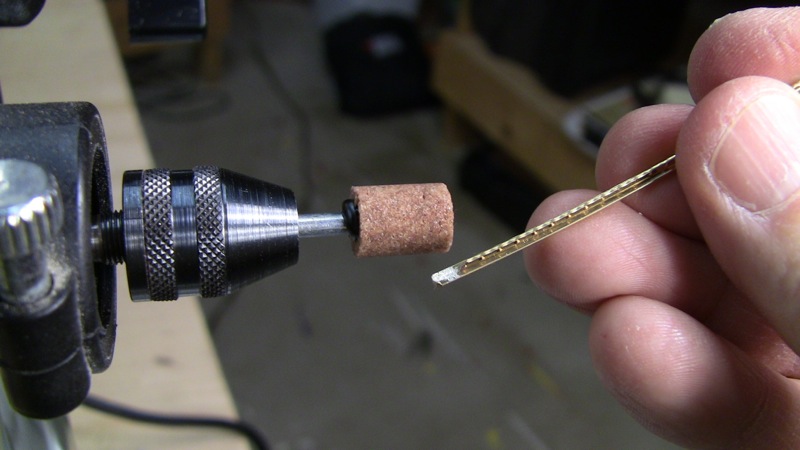

Joined: October 2005 Posts: 4079 Location: Utah | All that's left now is to install new frets. Because of the binding the tang has to be removed on the ends of the frets. This is another labor intensive part of this job, and another reason to send it back to Mother! Each fret has to be carefully nipped and then carefully ground flush where it will sit on top of the new binding. For this guitar I'm using EVO Gold fret wire. It is much harder than regular nickel silver wire and thus a lot more work. But it looks great! More pics of the frets when they're finished. Right now they're all glued in but not filed, beveled, or leveled.  | ||

| |||

| marenostrum |

| ||

Joined: August 2007 Posts: 1008 Location: Tuscany, Italy | Thank you !! | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2344 Location: Pueblo West, CO | Nice job, Steve. It's pretty timely, too. I've got a 1617 on the way that's missing the binding around the fretboard, so I'll get to do the same job on it. That's a good idea using nippers to clip the excess plastic. My first attempt at making a mold for the moustache binding was just two pieces of wood, like what you made. After a few attempts and choice words, I decided to make one side fixed and the other one sliding. I did this mainly to be able to get the clamps into place before the plastic cooled down. Your mousetache trim turned out great! It looks like a factory job, which is saying a lot. Edited by DanSavage 2014-10-04 2:57 AM | ||

| |||

| BanjoJ |

| ||

Joined: September 2012 Posts: 815 Location: Thredbo, NSW, Australia | Thank you Steve. I really enjoy and appreciate the efforts that you and others make here in sharing your knowledge. Sharing knowledge is what this site is about, but some put in just that extra bit of effort in doing so. Thanks again. | ||

| |||

| SOBeach |

| ||

Joined: April 2010 Posts: 823 Location: sitting at my computer | Nicely done!! Thanks for sharing the know-how.

BFLG forum ROCKS! | ||

| |||

| FlySig |

| ||

Joined: October 2005 Posts: 4079 Location: Utah | DanSavage - 2014-10-04 1:53 AM I've got a 1617 on the way that's missing the binding around the fretboard, so I'll get to do the same job on it. That's a good idea using nippers to clip the excess plastic. My first attempt at making a mold for the moustache binding was just two pieces of wood, like what you made. After a few attempts and choice words, I decided to make one side fixed and the other one sliding. I did this mainly to be able to get the clamps into place before the plastic cooled down. Your mousetache trim turned out great! It looks like a factory job, which is saying a lot. The one thing I would have liked to have done better is getting a clean edge to the clearcoat when removing the old binding. I'll give it another pass or two of super glue followed by wiping with acetone to smooth it out. The rest of the job is not critical and can be reworked or redone if messed up. Also, drilling side dots after installing blank binding would be superior if one has the right jigs and tooling to hold the neck in the correct and consistent orientation. For the mustache I made several molds before getting a good one. Your jig with one end secured is a lot better than mine. Ideally a multi-piece mold would work better to get the center point sharper. The next time around I'll experiment with one mold to make just the center crease, and then a second mold to do the entire mustache. For trimming excess binding I tried several methods including using a drill bit as a router bit, but that didn't work so well. The nippers work great to remove the majority. Then files finished it off quickly enough. Sanding the binding smooth to the fretboard meant scuffing the already sanded fretboard a bit, which means a little bit of rework on the wood to get it smooth again. But ultimately that sequence seems better than doing all the sanding after the binding is attached. Edited by FlySig 2014-10-04 5:25 PM | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2344 Location: Pueblo West, CO | FlySig - 2014-10-04 3:23 PM For trimming excess binding I tried several methods including using a drill bit as a router bit, but that didn't work so well. The nippers work great to remove the majority. Then files finished it off quickly enough. Sanding the binding smooth to the fretboard meant scuffing the already sanded fretboard a bit, which means a little bit of rework on the wood to get it smooth again. But ultimately that sequence seems better than doing all the sanding after the binding is attached. I used a scraper to bring the moustache binding on my 1619 level with the fretboard. I like using a scraper better than sandpaper because it doesn't scuff the wood and leaves the surface of the plastic smooth. | ||

| |||

| FlySig |

| ||

Joined: October 2005 Posts: 4079 Location: Utah | I'm still learning how to use a scraper. It worked ok for me on the sides to get the excess squeeze out off, and to knock down excess super glue. For such a simple tool it seems to take some practice to learn how to put a good edge on it and get smooth results. | ||

| |||

| DanSavage |

| ||

Joined: June 2012 Posts: 2344 Location: Pueblo West, CO | True. Once you do learn, it's a very valuable tool to have around for wood working. As it turned out I learned how to put an edge on scrapers when I learned how to sharpen a knife many moons ago. Both require the creation of a burr along the cutting edge. The difference is that the burr on a knife edge is taken out with a stone as the edge is polished where as the burr is left on the edge of a scraper. Luckily, any piece of steel with a sharp corner can be used to scrape down plastic, including Xacto blades/chisels, single-edge razor blades. I used an Xacto chisel to scrape all the finish off the abalone purfling and binding on my 1619. The finish was far too thick to chisel it off, so I just turned the chisel on edge and dragged it across the surface. I've done the same thing with Xacto #11 blades, too. | ||

| |||

| numbfingers |

| ||

Joined: January 2006 Posts: 1131 Location: NW Washington State | I have an unfinished Preacher Deluxe or UKII neck with a similar problem. It's missing a bit of binding after the last fret dot.

I wonder if it might be possible to replace just the missing piece? I know that I don't have the skill or patience to replace all of the binding and the dots. I think this neck was never finished because of the binding problem. It has a nice Ovation logo and the frets look new. There's a "2" written in the truss rod pocket that might indicate it was a second. I've been keeping it as a spare in case I damage one of my solidbody necks. | ||

| |||

| FlySig |

| ||

Joined: October 2005 Posts: 4079 Location: Utah | That would be an easy fix. Working around that last dot would be a bit fiddling, but all you have to do is fit a piece of binding in there and glue it in. If the mustache is loose it would be easy to glue back on. Clearcoating the neck would be the hardest part of getting that neck into service. | ||

| |||

| Jump to page : 1 Now viewing page 1 [25 messages per page] |

| Search this forum Printer friendly version E-mail a link to this thread |

| This message board and website is not sponsored or affiliated with Ovation® Guitars in any way. | |

| (Delete all cookies set by this site) | |