|

| ||

| The Ovation Fan Club | ||

| ||

| Random quote: "Believe me when I say that some of the most amazing music in history was made on equipment that's not as good as what you own right now." - Jol Dantzig |

Starting Tuneup on My 1617 Tonight Starting Tuneup on My 1617 Tonight

| View previous thread :: View next thread | |

| Members Forums -> About my guitar... | Message format | |

| HEADKNOCKER |

| ||

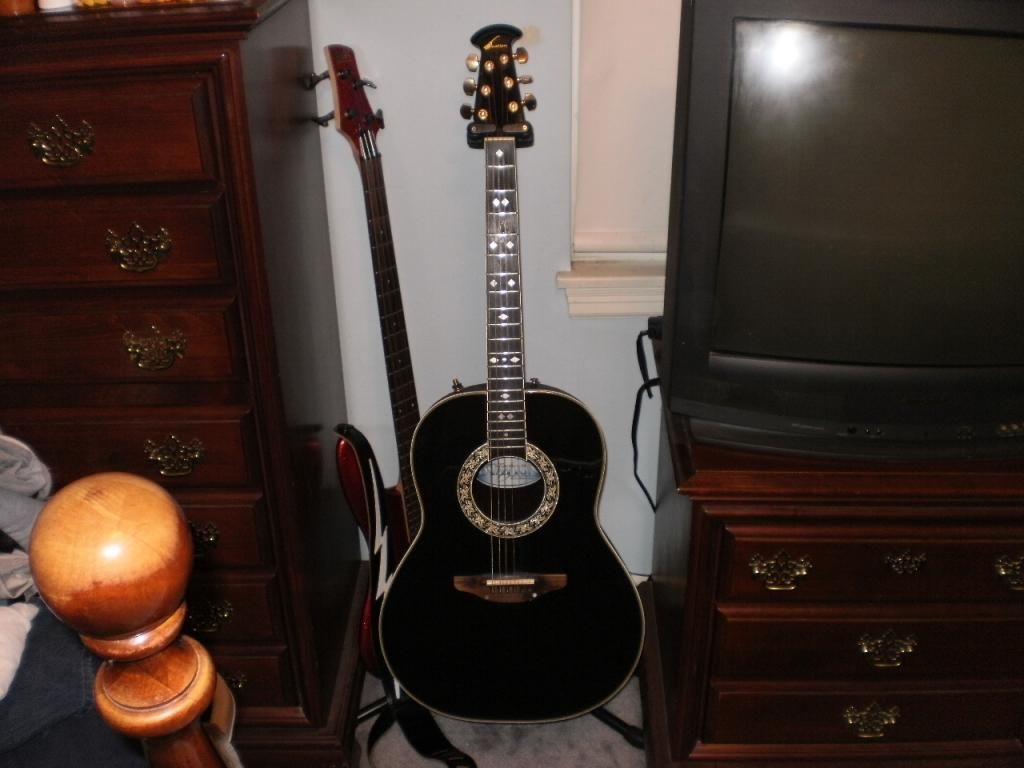

Joined: July 2014 Posts: 14 | Well I've gotten around tonight messing with the Ovation 1617 first thing was to get those old strings off & clean up the bridge & fret board.. I used lighter fluid then steel wool on the bridge after I pulled the piezo out to get all the dark stains off of it & then cleaned the ebony fret board up with steel wool then lemon oiled both.. I also removed the control assembly = pot & battery box etc in order to put some tuner lube/deoxit into the dual pot assembly... The Pots are sealed so I had to dribble spray the sauce into the pot via the shaft of the pot & then turn it in order to get some in there to smooth it up & make it feel less gritty as if it were full of dust , It came out much smoother & I also put a new Lithium battery into the battery box.. The shims under the piezo have me puzzled as there are the two factory shims, one is stairsteped on the treble side & there were two itty bitty pieces of wood one under the EA & one under the DG they were .010" & .035" thick? I went ahead & made a few brass & stainless shims out of some old feeler guages but have some old spruce scraps in the shop I can cut & shape into whatever I need.. I can also cut and shape some thin aluminum shims as well if I have too.. I'm gonna also make sure the neck bolts are snug & may give the neck a few thousanths more relief before I string it up.. I took a few pictures of the 1617 & a few of the bridge & control assembly/battery box.. Gary/Hk 1982 1617

Shims Two factory & two small pieces of popcycle stick & two metal ones I made, one stainless, one brass

| ||

| |||

| MWoody |

| ||

Joined: December 2003 Posts: 13996 Location: Upper Left USA | Looking good! Play it loud and often. | ||

| |||

| FlySig |

| ||

Joined: October 2005 Posts: 4081 Location: Utah | Is the bottom of the saddle slot level? The extra little shims may have been in there to flatten it out. One of my older O's has a slot which dips down at both ends probably about .010". I shaved some hardwood wedges to fit and then glued them in to level it out. | ||

| |||

| HEADKNOCKER |

| ||

Joined: July 2014 Posts: 14 | That's what's got me puzzled? I really can't quite figure out why the shims were used the way they were? If you look at the one picture it appears that the slot is cut deeper on the treble side but it's nice & smooth all the way across & being the top of the bridge is arched it makes it hard to determine if it's not flat by measuring with my digi-caliper across the top.. The shims were stacked in such a way that there is a empty space in there in more than one area, NOTE : shims are on the treble side only & the stairsteped factory shim was as well, stacked up like the attached picture.. I'm almost now tempted to recreate the total thickness of all the pieces flat & paralell out of brass or aluminum & fit it exactly down to small hole etc for the piezo/pickup wire & mounting pin? I've got a few chores to do tonight & will be going to Home Depot & may pickup a scrap of aluminum stock to mold into said shim if it should arise.. The guitar had great tone & played fine? Go figure Huh? It did buzz slightly on the open low E when played hard so I may give it a bit more relief, It has very little, also it appears the truss rod allen wrench is a 3/16" adjust via the sound hole on this model.. Thanks to all for any help or info.. Gary/Hk Stack of shims ??? The brass shim I cut to the left is .010".. I haven't measured the total thickness of the shims YET!!

Imagine all the dead air spaces inside & under the peizo saddle with the shims stacked as they were, The botttom of the pickup is flat & smooth & the aluminum isn't even scratched Looks to be a Total "TONE ROBBER" Edited by HEADKNOCKER 2014-07-09 5:55 PM | ||

| |||

| HEADKNOCKER |

| ||

Joined: July 2014 Posts: 14 | This vidio was helpfull though I wish I had the three shims in different thicknesses & the one tappered one.. https://www.youtube.com/watch?v=JepfhqFXB-8 I suppose that Ovation must have with lots of reserch came up with the use of the fiber shims, It could be possible that they have better tone transfer than spuce, brass or aluminum.. Hard to believe.. Now to go rob a board out of that old rubbish PC in the basement, I knew it would come in handy someday for something..OH YEAH!! The Super TONE Green Shim Baby with Gold contacts yet.. | ||

| |||

| HEADKNOCKER |

| ||

Joined: July 2014 Posts: 14 | I decided to put the two itty bitty shims at the bottom of the stack on the treble side were I found them & the two factory shims on top put the piezo back in & strung the guitar up, I also tightened the two neck bolts with a 7/16" 1/4" drive socket wrench & they both turned way more than I would have expected, I also gave a bit more relief to the neck via the truss rod wrench.. I have some polishing compound & was once a body man & being this guitar is black & 32 years old took a micro fiber rag to the top & tried to get some of the scratches out & shine the old girl up a bit & wiped her down really good while the strings were off = Tune Up with Oil Change & Spark Plugs.. I just finished stringing the guitar up but haven't brought it to pitch yet being it's 1:00am and my wife & son are asleep but they'd do it to me & you only live once.. So after I finish this post i will tune her up & clip the string & play a few chords & wait till my son wakes up to let him do the first test drive of the 1617 with new tires.. | ||

| |||

| FlySig |

| ||

Joined: October 2005 Posts: 4081 Location: Utah | Shim material does affect the tone. I don't know if the factory selected for tone reasons or because the little fiberglass stuff (which looks exactly like circuit board material) comes in precise thicknesses and is very easy to work with. Factory shims that I've measured are either thin (.021" Too much mass can absorb energy, robbing the guitar of tone and volume. Different materials can absorb different frequencies and affect the tone. I've tried an ivory shim sanded to precise thickness (.093" Edited by FlySig 2014-07-10 9:44 AM | ||

| |||

| jay |

| ||

Joined: January 2009 Posts: 1249 Location: Texas | I can understand being particular about shim choice when you have a bone (or whatever) saddle between the string and the bridge...but A/E have whatever the piezeo saddle substance is that is encased in plastic separating the string from the bridge. I have always wondered whether a 1117 and a 1617 from the same year, acoustically, produce a noticible difference in sound because of the two completely different saddles.

Edited by jay 2014-07-10 12:35 PM | ||

| |||

| Mark in Boise |

| ||

Joined: March 2005 Posts: 12761 Location: Boise, Idaho | The #47 RI and the OFC Adamas are essentially the same guitar except for the saddle and pickup. The sound is noticeably different. I don't know if it's the difference in the saddles or the addition of the preamp. That's the closest comparison I have of two same guitars with different saddles. If someone has a 1117 and 1617 of the same year, I would guess that the 1117 sounds better, but there are too many variables in guitars, especially all wood guitars, that could affect the difference. | ||

| |||

| HEADKNOCKER |

| ||

Joined: July 2014 Posts: 14 | Well the only trouble I'm facing currently is the output jack doesn't want to stay plugged in right? & I assume I tightened it too tight so I loostened it slightly but it's still acting up some, I guess I'll loosten the strings after a while & try an flip the inner lock washer over, I did notice the outer washer had a curvature that matched the back of the guitar.. The guitar is playing OK & the action is really low with little to no buzz on the low E, Tone seems to be fine as well.. The only way I could figure to cut shims out of a piano key would be with a back saw in a miter box & then to sand them to perfect thickness afterwards, ebony is pretty darn hard.. | ||

| |||

| HEADKNOCKER |

| ||

Joined: July 2014 Posts: 14 | Tried a different/better cord & all is OK!! I guess that Fender cord is Rubbish? & The Nuetrix one is Primo.. My son had it upstairs playing it threw his Peavey Tube 60 Vypyr & had to turn it up to 6 to hear the guitar amplified over the guitars unplugged volume, This guitar has gusto, I could hear it very well down here on the 1st floor with the door closed.. I also forgot to state before that I have this guitar setup tuned down 1/2 step that's why I had to loosen the truss rod slightly during my setup to allow the action a bit more relief.. | ||

| |||

| Jump to page : 1 Now viewing page 1 [25 messages per page] |

| Search this forum Printer friendly version E-mail a link to this thread |

| This message board and website is not sponsored or affiliated with Ovation® Guitars in any way. | |

| (Delete all cookies set by this site) | |