|

|

Joined:

June 2012

Posts: 2345

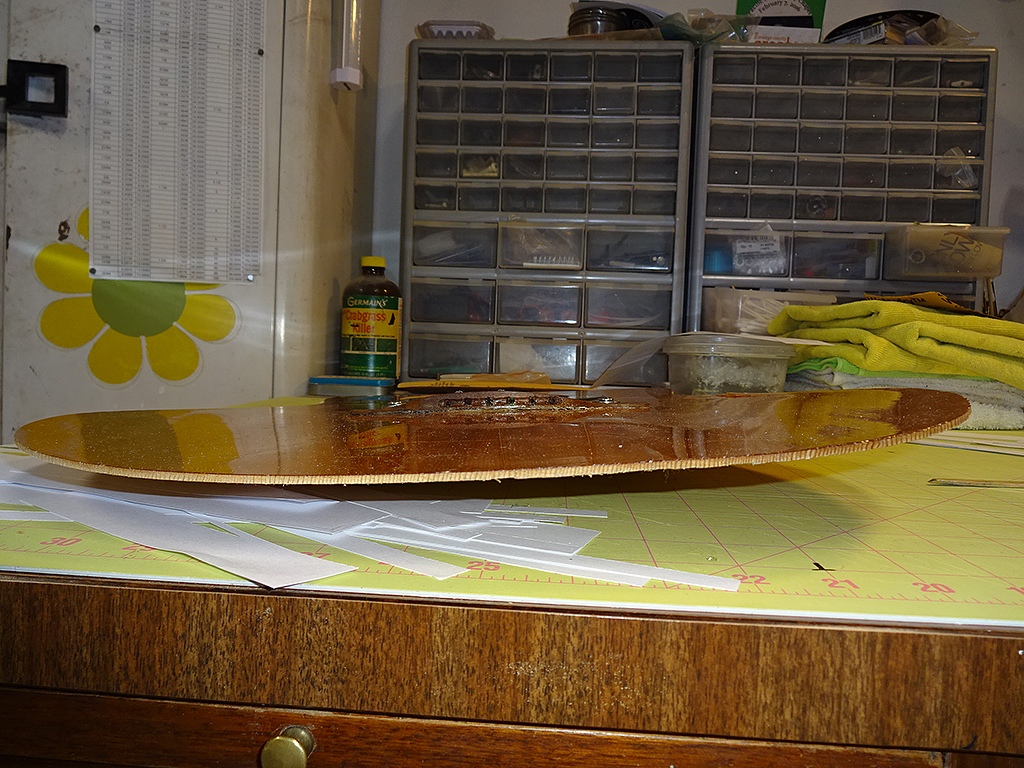

Location: Pueblo West, CO | Reading Patch's thread about split top on his 'Book' Elite reminded me that I've been wanting to pass along this info about what I think is the root cause of the splits in the tops that happens all too often on our Os. Even my 'Book' Elite is starting to get finish cracks in the lower bout. When Paul Moody had me re-top his 1113, it arrived with three splits that ran the length of the top from the upper bout to the lower bout, one each on either side of the bridge and a third that went right down the middle. Here's a pic of what the top looked like before I pulled it off the guitar.

In the process of pulling the top off the guitar, all fourn transvers braces pulled off the top. Since I wasn't going to be using the top, I just left them off. I went on with re-topping the guitar and didn't give it another thought, until recently.

Then, when pulling the tops off of the four guitars I'm working on now, I noticed something unusual. All the tops were cupped, to a lessor degree than Paul's 1113 top, but they all were cupped. Here's the 1113 top. This photo shows the cracks a little better. This top is the worst because it has no braces across the grain to hold the top flat.

And, the 1528 top.

The 1612 top.

Lastly, Paul's 1117 top.

So, I got to thinking about would cause all these tops to warp. All were different types of wood and different ages. Paul's 1117 was the newest, being rebuilt at the factory. The only common denominator was the finish -- poylester resin. When molding fiberglass parts, one of the benefits of using epoxy over polyester is what's known as dimensional stability. In common terms, polyester resin shrinks. Not much, but it's enough that most quality parts are molded from epoxy. There are other reasons for using epoxy over polyester, but one of the big ones is shrinkage. Stabilizers can be added to polyester resin to help minimize it, but it will still shrink. If polyester resin were used on one side of thin wood, like our guitar tops, and it were to shrink, it would warp the wood unevenly. Since the tops are firmly glued to the edges of the bowl, any shrinkage would eventually cause the finish, and even the wood, itself, to split. So, the conclusion I've come to is that the finish cracks we so often see in our Os is caused by the shrinking polyester finish. What can we do about it? Short of the factory using a different finishing system, Not much. I just thought I'd pass along this info to remove the mystery of why our guitars' finish cracks.

Edited by DanSavage 2017-02-03 6:32 PM

|

|

| |

|

Joined:

December 2015

Posts: 287

Location: Katmandu | I always thought it's due to the A or fan bracing not providing the soundboard enough structural support right around where the bridge is located at when compared to the more structurally sound X bracing, or due our bridges being secured with screws through the top, thereby increasing the risk of it ripping the soundboard whenever it decides to lift off.

In any case, I'm glad my A-braced 1717 is more domed than anything. |

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | Yeah, with the tension of the strings, the tops will dome (belly) below the bridge. But, it you were to remove the top from the bowl, you'd probably see it warp as these tops have done.

All the other tops on my 'trophy wall' are similarly warped.

Edited by DanSavage 2017-02-03 8:00 PM

|

|

| |

|

Joined:

February 2016

Posts: 1882

Location: When?? | Looking at those tops is like watching a crash reel. I don't doubt your conclusion on the polyester shrinkage, though I do wonder why so many cracks, especially ones that go all the way through the wood, result with the fissures opening outward on the finished side since the cupping force is upward and away from the bowl at the edges. I would think that the crack's major opening would be on the underside of the wood, and be more pinched closed on the finished side. Or are they? The photos don't really show the difference per side. |

|

| |

|

Joined:

April 2014

Posts: 103

Location: Ontario Canada | very fascinating Dan, i really enjoy reading a lot of your posts! does the factory still use the exact same finish today? if so, is there a better alternative? "that stuff should be outlawed"

your pulling tops over there like your pulling teeth, curious how do you get them off? |

|

| |

|

Joined:

November 2002

Posts: 3663

Location: Pacific Northwest Inland Empire | Makes sense. There are differential forces & material integrity, so when the polyester goes, it takes the wood fibers with it. Then, when the top is removed. the polyester attempts to "go home", and you get the cupping!

As to alternatives to finish materials, that's probably a production & cost issue. May be cheaper, or more efficient in sense of time, to use the polyester.

The Ovations I have reconstructed have used either varnish, speeded linseed oil, or lacquer, being pretty thin, too. Don't believe any have cracked, but some were about 15 years ago, now, & the new owners have not sent any complaints (yet).

|

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | Love O Fair - 2017-02-03 7:55 PM

Looking at those tops is like watching a crash reel. I don't doubt your conclusion on the polyester shrinkage, though I do wonder why so many cracks, especially ones that go all the way through the wood, result with the fissures opening outward on the finished side since the cupping force is upward and away from the bowl at the edges. I would think that the crack's major opening would be on the underside of the wood, and be more pinched closed on the finished side. Or are they? The photos don't really show the difference per side.

Under normal circumstances, the wood swells and shrinks a little bit according to the ambient humidity. To prevent cracks in the wood on a flat-top guitar, the builder will dome the top a little bit as they're gluing on the braces. Martin guitar tops are built on a 28-foot radius dish. This doming allows the wood to shrink in lower humidity without splitting.

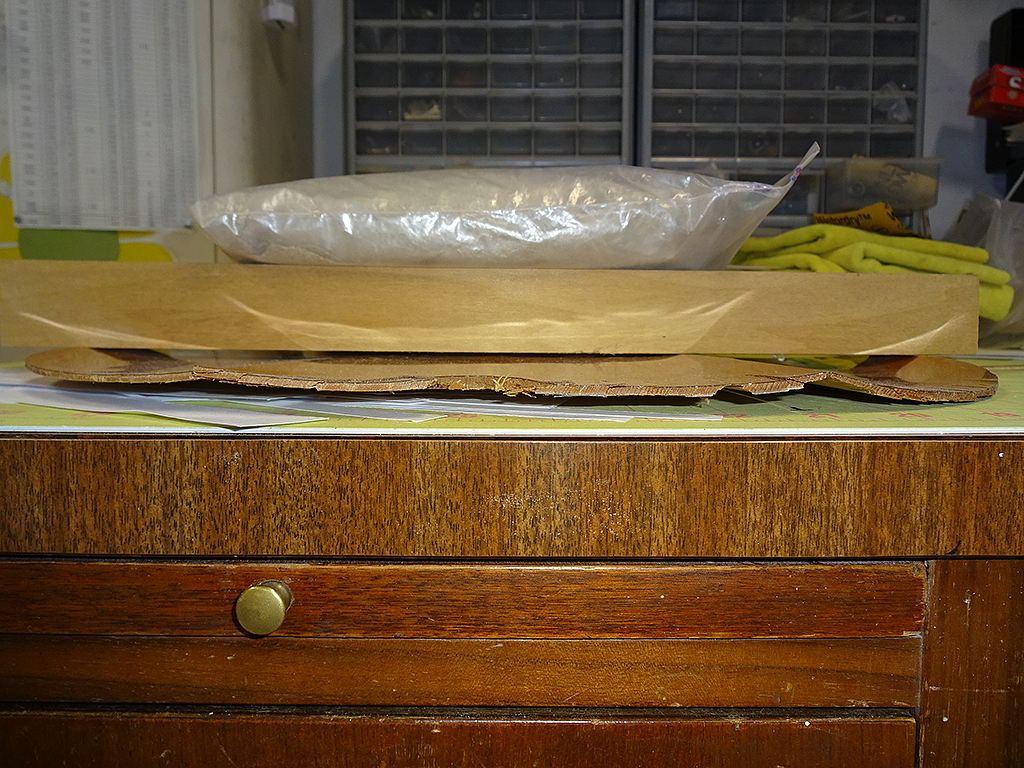

Here's what's probably happening. It'll be easier to understand if you have something to look at. I laid a piece of wood across the 1113 top, then weighted it to roughly simulate the top being attached to the bowl.

As you can see, the top has three main waves, each separated by the cracks. What it looks like to me is happening is that the polyester continues to shrink, but the wood doesn't. As it shrinks, the wood deflects inward. At some point, when the wood can deflect no more, either the finish will split or the wood will, usually in spots where there is no bracing on the underside to support it.

|

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | Thunderbolt - 2017-02-03 9:17 PM

very fascinating Dan, i really enjoy reading a lot of your posts! does the factory still use the exact same finish today? if so, is there a better alternative? "that stuff should be outlawed"

your pulling tops over there like your pulling teeth, curious how do you get them off?

I couldn't say for sure, but I'd imagine they're still using the same finish.

Taylor is using a UV-cured polyurethane finish. Here's a couple of really interesting youTube video of their finishing system.Taylor Factory Tour Part 3 of 4 - Finish Application Taylor Innovation: Electrostatic Finish Spraying and UV-Curing To get the tops off, first I pull the binding. Depending on the top, sometimes I also pull the purfling to expose the glue joint between the top and lining.

Next, I use an Xacto chisel to separate the top from the lining. This part takes a little while to do, maybe 20-30 minutes.

|

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | seesquare - 2017-02-04 8:36 AM

Makes sense. There are differential forces & material integrity, so when the polyester goes, it takes the wood fibers with it. Then, when the top is removed. the polyester attempts to "go home", and you get the cupping!

As to alternatives to finish materials, that's probably a production & cost issue. May be cheaper, or more efficient in sense of time, to use the polyester.

The Ovations I have reconstructed have used either varnish, speeded linseed oil, or lacquer, being pretty thin, too. Don't believe any have cracked, but some were about 15 years ago, now, & the new owners have not sent any complaints (yet).

Yeah, solvent-based polyester is probably the cheapest of the durable polymer finishes.

I used rattle-can Minwax polyurethane and it works pretty well and buffs out to a good shine. My only real complaint is that it's a little on the soft side, almost like lacquer.

I used this as a primer/sealer on Jay's Balladeer, then top-coated it with 2K Eastwood urethane. I liked how that worked out, so I'll probably be using this on all the guitars in the future. It's a little more expensive, but it works pretty good.

|

|

| |

|

Joined:

November 2002

Posts: 3663

Location: Pacific Northwest Inland Empire | How long do you let the polyurethane set up, before you buff it out? Fortunately, we have, almost year-round 40-to-50% humidity, albeit a bit drier in the cold months, with heating, so we don't have a lot variation of humidity. I'm usually giving the finish a full 14 days, before even breathing hard on it.

|

|

| |

|

Joined:

December 2004

Posts: 578

Location: Denmark | Good observation and thinking. In theory a similar coat on the backside of the top might stabilize to some extent, but only to some extent. Partially due to even pull on front and back, and partially due to reduce the humidity variations in the wood. Do the plywood tops (Celebrities ...) show similar behaviour? |

|

| |

|

Joined:

February 2014

Posts: 715

Location: moline,illinois | Very interesting observations as usual Dan,one does wonder how you can have a guitar like my 1972 Glen Campbell 1127 with a perfect top and another like patch's book elite that cracks right in the center of a section,do you think it has something to do with the stability of each piece of wood being different since they come from different trees so perhaps some have microscopic weaknesses not visible in the grain pattern that cause them to give under prolonged stress.

Your wall of replaced tops is like little a graveyard of ovations that have been resurrected by Dr Savage,maybe they're Frankenstienien guitars brought back by Dr Dan-enstien to haunt the night LOL.

(IMG_1157.JPG) (IMG_1157.JPG)

(IMG_1160.JPG) (IMG_1160.JPG)

Attachments

----------------

IMG_1157.JPG (58KB - 0 downloads) IMG_1157.JPG (58KB - 0 downloads)

IMG_1160.JPG (53KB - 0 downloads) IMG_1160.JPG (53KB - 0 downloads)

|

|

| |

|

Joined:

December 2015

Posts: 287

Location: Katmandu | DanSavage - 2017-02-04 11:08 AM As you can see, the top has three main waves, each separated by the cracks. What it looks like to me is happening is that the polyester continues to shrink, but the wood doesn't. As it shrinks, the wood deflects inward. At some point, when the wood can deflect no more, either the finish will split or the wood will, usually in spots where there is no bracing on the underside to support it. This makes a lot of sense. Those three main waves are evident on my 1717 as well. I can feel each wave when running my hand over the soundboard. *sadface* |

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | seesquare - 2017-02-04 11:58 AM

How long do you let the polyurethane set up, before you buff it out? Fortunately, we have, almost year-round 40-to-50% humidity, albeit a bit drier in the cold months, with heating, so we don't have a lot variation of humidity. I'm usually giving the finish a full 14 days, before even breathing hard on it.

When spraying polyurethane, I've been waiting a couple of days, but I don't think that's enough. I usually test it by seeing if I can dent it with a fingernail. But, as I've been discovering, the Minwax polyurethane works good as a primer sealer, but it's a little soft for the final coats. That's why I'm going back to the 2K Eastwood urethane. |

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | tpa - 2017-02-04 2:12 PM

Good observation and thinking. In theory a similar coat on the backside of the top might stabilize to some extent, but only to some extent. Partially due to even pull on front and back, and partially due to reduce the humidity variations in the wood. Do the plywood tops (Celebrities ...) show similar behaviour?

Spraying the backside might help keep it from cupping because of equal shrink rates, but that would introduce its own set of problems, such as decreased repairability.

Yes. The 1528 show above is a plywood top and it's cupped. The cross-grain would probably help keep it from splitting, though. |

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | 2wheeldrummer - 2017-02-04 4:02 PM

Very interesting observations as usual Dan,one does wonder how you can have a guitar like my 1972 Glen Campbell 1127 with a perfect top and another like patch's book elite that cracks right in the center of a section,do you think it has something to do with the stability of each piece of wood being different since they come from different trees so perhaps some have microscopic weaknesses not visible in the grain pattern that cause them to give under prolonged stress.

Your wall of replaced tops is like little a graveyard of ovations that have been resurrected by Dr Savage,maybe they're Frankenstienien guitars brought back by Dr Dan-enstien to haunt the night LOL.

That's a good question. Why do some crack/split and others don't? I wish I had the answer.

Here's a pic of my 'trophy wall'. Actually, I keep these tops around as a reference library, mainly for the brace patterns. It will be expanding when I add the four tops to the guitars I'm working on now.

Edited by DanSavage 2017-02-05 6:01 PM

|

|

| |

|

Joined:

March 2002

Posts: 15679

Location: SoCal | Interesting to look and see that two of those tops were mine...... |

|

| |

|

Joined:

May 2011

Posts: 760

Location: Muenster/Germany | Many old A-braced Ovations have "waves" on the top where the braces are. Mine had a cupped top between the 2 outer braces in front of the bridge, at least 5-6mm deep.Looked awful and I was afraid that the top would break.

I picked up all my courage and built a simple construction that I could put in the guitar and thus make enough pressure on the top from inside so that it became nearly straight. Then I used an infrared lamp and carefully heated the top from outside, so that I could hardly touch ist ; I would estimate 50-60° C. I proceeded with this for about half an hour, let the whole thing rest over night and repeated the procedure. The waves on the side of the top (where the braces are) are still there but the rest is satisfactorily plain again. No cracks, no problems.

Sure the finish will shrink with the time, nearly all plastic materials do. I am an Optician. If you use older plastic eyglasses frames and you don´t make the lenses a little smaller time after time the frames will break, that´s no big surprise for me.

But maybe we could remove the tension of the finish with little heat? Did you try that one of the curved tops? |

|

| |

|

Joined:

January 2009

Posts: 1249

Location: Texas | There is a 50 year old rosette in that picture. |

|

| |

|

Joined:

December 2004

Posts: 578

Location: Denmark | https://www.youtube.com/watch?v=CXX36b_mlMo |

|

| |

|

Joined:

February 2016

Posts: 1882

Location: When?? | Detlef... that is a very interesting story and result. I don't think I'm ready to dare that for starters on anything nice, but my niece has a trasher that I think I'll try it on just to check it out. Thanks for the recipe.

Oh, and what was your construction made of? How much pressure did you adjust it to? I'm thinking some kind of MacGyver-type thing with threads that can be used as an expander, braced against the inside of the guitar's back with flat wood, and connected to another piece of flat wood cut to fit the specific shape of the cupped area and pressed against the inside of the top.

Edited by Love O Fair 2017-02-06 8:01 PM

|

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | moody, p.i. - 2017-02-05 10:46 PM

Interesting to look and see that two of those tops were mine......

Yes, but I don't think that has anything to do with how you treat your guitars. :D |

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | DetlefMichel - 2017-02-06 8:13 AM

I picked up all my courage and built a simple construction that I could put in the guitar and thus make enough pressure on the top from inside so that it became nearly straight. Then I used an infrared lamp and carefully heated the top from outside, so that I could hardly touch it ; I would estimate 50-60° C. I proceeded with this for about half an hour, let the whole thing rest over night and repeated the procedure. The waves on the side of the top (where the braces are) are still there but the rest is satisfactorily plain again. No cracks, no problems.

Sure the finish will shrink with the time, nearly all plastic materials do. I am an Optician. If you use older plastic eyglasses frames and you don´t make the lenses a little smaller time after time the frames will break, that´s no big surprise for me.

But maybe we could remove the tension of the finish with little heat? Did you try that one of the curved tops?

Wow! You're a brave man to apply 150-degree (F) heat to an otherwise perfect guitar, all in the name of BFLG science. LOL!

Actually, 150 F degrees would be barely warm enough to get the resin to its Tg temperature. Usually, it's up around 200 F degrees, so you were pretty safe. (Whew!)

When I was flying model airplanes, I covered my models with Monokote (known in the hobby as 'Moneykote') which is a heat-shrinkable mylar film with an a heat-sensitive adhesive combined with pigment. Moneykote was shrinkable to a certain point, but it would only shrink so much.

I tried heating the lower bout of Paul's 1113 top with my handy-dandy heat gun, which can easily get materials up over 200 F degrees. It did soften the finish, which allowed it to deform a little bit. But, as you noted, without holding it into place, it returned to its original shape as it cooled.

The heat-deformation of the top would not unlike a bowl-bend. As you experienced, when I did this to Jay's Balladeer, I needed to clamp it into position, then heat it and let it cool while still clamped. Even so, it took several cycles to get the bowl to the point I wanted.

Still, this does make for an interesting discussion.

|

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | jay - 2017-02-06 9:19 AM

There is a 50 year old rosette in that picture.

Yep. Between the top from #485 and my 1617, there's almost 100 years of combined Ovation history on that wall. :D

Edited by DanSavage 2017-02-06 9:26 PM

|

|

| |

|

Joined:

May 2011

Posts: 760

Location: Muenster/Germany | Love O Fair - 2017-02-07 2:43 AM

Detlef... that is a very interesting story and result. I don't think I'm ready to dare that for starters on anything nice, but my niece has a trasher that I think I'll try it on just to check it out. Thanks for the recipe.

Oh, and what was your construction made of? How much pressure did you adjust it to? I'm thinking some kind of MacGyver-type thing with threads that can be used as an expander, braced against the inside of the guitar's back with flat wood, and connected to another piece of flat wood cut to fit the specific shape of the cupped area and pressed against the inside of the top.

Oh no, I´ve just used some pieces of styrofoam that I had left from a package for my printer...Idid not take measurements of pressure or temperature, I just followed my intuition. I could have failed badly with this, but all was better than the guitar top before.

The guitar is a 1979 1119 with an extremely fine grained spruce top. I never saw a sitka with such fine lines, the colour is normal but it looks like a red spruce. I guess that fot too many years there had been too hard strings on the guitar, and maybe it was not played for a longer time and stored in the case with full string tension.

I use now very light strings with less than 10 lbs tension per string and the guitar sounds and plays phantastic, it´s the best playing of all my Ovations, despite of several bad finish cracks, nicks, scratches and waves on the top. I can play it with a 2mm string action with no buzz and the neck, neck angle and frets are perfect.

I would advice all of you who use old A-braced Ovations, not to use the .12-.53 "tow ropes" on these guitars, better use lighter strings. I prefer the Thomastik "plectrum" .11-.50 by Thomastik-Infeld.

Recently I bought the 1619 "Dan Savage" with the bearclaw top and forward X braces and even this guitar sounds VERY impressive with the Thomastiks.

|

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | DetlefMichel - 2017-02-07 7:34 AM

I would advice all of you who use old A-braced Ovations, not to use the .12-.53 "tow ropes" on these guitars, better use lighter strings. I prefer the Thomastik "plectrum" .11-.50 by Thomastik-Infeld.

Recently I bought the 1619 "Dan Savage" with the bearclaw top and forward X braces and even this guitar sounds VERY impressive with the Thomastiks.

I use Extra Light Elixir 80/20 Nanoweb strings on my deep-bowl Os (.10-.47) for this very reason.

You'll definitely want to use the lightest strings you can get on the 1619. When I built that guitar I thickness-sanded it down to .094" instead of the usual .100" to get the maximum response out of it.

What is the alloy of the Thomastik-Infeld strings? Are they phosphor-bronze or 80/20 bronze? |

|

| |

|

Joined:

February 2016

Posts: 1882

Location: When?? | @Detlef ->>Thomastik "plectrum" .11-.50 by Thomastik-Infeld.<<-

I see those at several suppliers.. they are the model AC-111, right? How much tension load do they take off in comparison to using the 12-53 "tow ropes"? A lot? How do they sound in comparison to, say, the D'Ad EXP-16s or the Adamas 1818s? |

|

| |

|

Joined:

March 2002

Posts: 15679

Location: SoCal | I believe that an Ovation needs strings on it heavy enough to drive the top. I've always played mediums (.13-.56) but have gone to lights (.12-.53). I believe that you lose a lot of tone with lighter strings. Dan knows this and the top on the Legend will be good for lights. I hope...... |

|

| |

|

Joined:

May 2011

Posts: 760

Location: Muenster/Germany | The AC 111 set has a tension of 125 lbs. I really don´t know what alloy it is but I`m quite sure that it is no phosphor bronce. These strings need careful cleaning (fast fret...). I have to admit that on some guitars they will sound a little too light, not really boombastic. But the TONE of these strings is remarkable, esp. when you like to play fingerstyle. On old 6 string guitars they can be the best for old guitar tops, but on 12 string guitars they are the absolute! ultimate! best! strings!!

I use Thomastiks because I have not so much physical power in the left hand due to chronical health problems with my forearm. I would never be able to play (or bend...) .12 or .13 strings. I know that my Martin D 45 guitar would sound greater with "normal" gauges, but I want to play it, so... |

|

| |

|

Joined:

May 2011

Posts: 760

Location: Muenster/Germany | Here the 1619 before and after the treatment:

not perfect, but enough for me now:

A litte strange looking: the top of my 1759 12string. No cracks! http://i1377.photobucket.com/albums/ah69/bluesman19591/Ovation%20repair/P1000199_zpseeqz03wh.jpg?t=1486468481 |

|

| |

|

Joined:

February 2016

Posts: 1882

Location: When?? | Detlef.. that last photo is blowing my mind. All that and no cracks.. amazing. What is the age of that 12er? |

|

| |

|

Joined:

May 2011

Posts: 760

Location: Muenster/Germany | The guitar is from 1991. Maybe the movement of the structure was so slow that the finish did go along with it. It really looks crazy when you see the guitar hanging on the wall from a certain angle. But it sounds amazing with endless sustain, ridiculously low action. Could it be that the wave-type structure of the top has an other kind of sound projection? Could be a nice object for physicists....

I use the low-stress Thomastik strings and keep the guitar always de-tuned one halfstep (like all of my 12strings). |

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | DetlefMichel - 2017-02-08 3:19 AM

The AC 111 set has a tension of 125 lbs. I really don´t know what alloy it is but I`m quite sure that it is no phosphor bronce. These strings need careful cleaning (fast fret...). I have to admit that on some guitars they will sound a little too light, not really boombastic. But the TONE of these strings is remarkable, esp. when you like to play fingerstyle. On old 6 string guitars they can be the best for old guitar tops, but on 12 string guitars they are the absolute! ultimate! best! strings!!

I use Thomastiks because I have not so much physical power in the left hand due to chronical health problems with my forearm. I would never be able to play (or bend...) .12 or .13 strings. I know that my Martin D 45 guitar would sound greater with "normal" gauges, but I want to play it, so...

That's pretty light tension. The Elixir extra lights have a tension of 131 lbs.

The lights have 158 lbs. and the mediums, 183 lbs.

Interestingly, the PBs have slightly higher tensions for all of the weights. (135 lbs, 162 lbs. & 188 lbs., respectively)

I use extra light strings on my torrefied tops for three reasons.

First, the tops are thinner than factory Ovation tops. The factory tops are tapered from .130" to .110". The torrefied tops are tapered from .120" to .100", so they would warp easier under the higher tension of mediums.

Second, and more importantly, I'm not sure what's the shear strength of the torrefied wood. I'm concerned whether the bridge would stay attached with the 183 lbs. of tension that the mediums exert. I know the bridge does stay attached with lights, but I haven't tried mediums and I'm not sure I want to find out on one of my guitars.

Now, a couple of bridge screws would help keep the bridge attached, but then the warping problem could rear its ugly head and accelerate the bellying of the top.

Third, I don't like how hard I have to push on the heavier strings when playing.

I treat the torrefied tops like I would a really old guitar and minimize the stress. |

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | moody, p.i. - 2017-02-07 9:00 PM

I believe that an Ovation needs strings on it heavy enough to drive the top. I've always played mediums (.13-.56) but have gone to lights (.12-.53). I believe that you lose a lot of tone with lighter strings. Dan knows this and the top on the Legend will be good for lights. I hope......

Your guitar should easily handle the lights. |

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | DetlefMichel - 2017-02-08 9:20 AM.

I use the low-stress Thomastik strings and keep the guitar always de-tuned one halfstep (like all of my 12strings).

I've always de-tuned my 12s down a full-step. When I got my 1655 I tried tuning it to concert pitch and after a while I noticed it started doing the same thing shown in your photo.

I de-tuned it back down, and the warping mostly went away. It still has a little bit of warping, but not nearly as much as what your photo shows. |

|

| |

|

Joined:

December 2004

Posts: 578

Location: Denmark | DanSavage - 2017-02-07 7:28 PM

First, the tops are thinner than factory Ovation tops. The factory tops are tapered from .130" to .110". The torrefied tops are tapered from .120" to .100", so they would warp easier under the higher tension of mediums.

Not that I did any of the math to check, but my sense poposes that the brace profiles have a big role in taking the bending action from the offset forces from string tension. Could be interesting to calculate the bending properties of a cross section of the top+brace profiles. |

|

| |

|

Joined:

March 2002

Posts: 15679

Location: SoCal | DanSavage - 2017-02-08 10:35 AM

DetlefMichel - 2017-02-08 9:20 AM.

I use the low-stress Thomastik strings and keep the guitar always de-tuned one halfstep (like all of my 12strings).

I've always de-tuned my 12s down a full-step. When I got my 1655 I tried tuning it to concert pitch and after a while I noticed it started doing the same thing shown in your photo.

I de-tuned it back down, and the warping mostly went away. It still has a little bit of warping, but not nearly as much as what your photo shows.

I have owned an Adamas 1 for over 20 years. It always has lights on it and is tuned to concert pitch. The top looks perfect and it sounds magnificent.

When I first got it, I put mediums on it. You could see the pull on the top. They came off in about 15 minutes......

Edited by moody, p.i. 2017-02-08 4:13 PM

|

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | tpa - 2017-02-08 11:39 AM

Not that I did any of the math to check, but my sense poposes that the brace profiles have a big role in taking the bending action from the offset forces from string tension. Could be interesting to calculate the bending properties of a cross section of the top+brace profiles.

The top and braces work together to resist string tension. Here's a good article by a structural engineer who's also a luthier that explains it.The Guitar As A Structure (And Some Practical Information On Bracing) Here's the meat of the article: To explain how the stiffness of the braces (and the rest of the guitar) works, I need to introduce some engineering measurements that are used to define the stiffness of structures. These measurements are section properties and material properties. Section properties are inherent to the shape of the structure. Material properties are inherent to the material it is made of. They act together to define strength and stiffness. Because engineers understand section properties and material properties (and properly apply them), buildings don’t fall down and airplane wings don’t fall off. Most people have a tactile, “horse-sense” understanding of section properties: If a wood plank is taller or wider, it will be stiffer (all other things being equal – this caveat applies throughout; I’ll not repeat it. In real life, things are never equal.) A thick Sitka spruce trunk is stiffer and stronger than a thin one. A ¼-inch thick guitar top is stiffer and stronger than a 3/32-inch thick top. These are all differences in section properties. Section properties are simply the exact way that engineers use to measure a “stiffer than” or “stronger than” structural shape. Section properties are determined exclusively by the shape and size of the structure. Section properties are not affected in any way by the material – this is the key point. A two-inch by four-inch plank will have the same section properties whether it is made of steel or plastic or butter. Section properties are essentially perfectly understood by engineers and have been tested and confirmed millions of times. They are simple to compute and formulas may be found in the suggestions for further reading (SFR) at the end of this article. Please note that a number of topics that are introduced in this article are discussed in much more detail in some of these suggested readings. Separate from section properties the other important factor is material properties. A two-inch diameter steel pipe is much stiffer than a two-inch diameter plastic pipe (both pipes have identical inside diameter (ID) and outside diameter (OD)). This is the material effect. Because the ID and OD are identical these two pipes have exactly the same section properties; they are different in stiffness (and strength) because they are made of different materials that have different inherent material properties. These inherent material properties are also precisely measured by engineers. The primary material property of interest here is the modulus of elasticity, abbreviated as E, and generally referred to as “Young’s Modulus.” The details on Young’s Modulus and how it is determined and used can be found in the SFR. The article goes on to discuss material properties. Basically, red spruce is stiffer than Sitka spruce, which is stiffer than Englemann spruce, which is stiffer than red cedar, etc. So, it's a combination of both that work to control the tension of the strings and are, in turn, affected by the tension of the strings.

|

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | moody, p.i. - 2017-02-08 2:11 PM

I have owned an Adamas 1 for over 20 years. It always has lights on it and is tuned to concert pitch. The top looks perfect and it sounds magnificent.

When I first got it, I put mediums on it. You could see the pull on the top. They came off in about 15 minutes......

Which is a perfect example of the differences in section and material properties as the above article discusses.

Basically, the CF/birch/CF laminate behaves very much like a cantilever beam.

The birch separates the two layers of CF so that each of them are able to resist both tension and compression. (bending forces) |

|

| |

|

Joined:

February 2016

Posts: 1882

Location: When?? | @Dan ->>The primary material property of interest here is the modulus of elasticity<<-

Funny.. in my case it's not "Young's" Modulus.. it's "Old's" Modulus.. since it was just the other day when drying from a shower that I noticed the skin sag on the back of my legs and wondered what the proper term for that condition would be. You suppose switching to a heavier gauge of jeans will help?

Aside from that... good article. Thanks for posting. |

|

| |

|

Joined:

February 2016

Posts: 1882

Location: When?? | My knowledge of guitar bracing is like, zip. So I read on. Figure 3 of the article gets into bracing shapes, including paraboloid. Now I'm picturing a paraboloid bracing strip as shaped something like a water flume flowing down a mountainside. Is that right? If so, then how in the heck would you securely glue (or otherwise attach) something like that to the back of a guitar top??

Edit: Okay, wait.. after more thought I think I might be wising up here. Is it flat across the bottom (as opposed to the flume example which is half-circle curved on the bottom) and glued on that flat side to the guitar's top wood, thus leaving two trough edges pointing upward and essentially doubling the bending modulus strength? Am I lost on this.. lol.

Edited by Love O Fair 2017-02-09 12:25 AM

|

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | Love O Fair - 2017-02-08 10:01 PM

My knowledge of guitar bracing is like, zip. So I read on. Figure 3 of the article gets into bracing shapes, including paraboloid. Now I'm picturing a paraboloid bracing strip as shaped something like a water flume flowing down a mountainside. Is that right? If so, then how in the heck would you securely glue (or otherwise attach) something like that to the back of a guitar top??

Yes. the paraboloid shape has the wider end (flat side) glued to the sound board.

I use the go-bars to clamp the pieces to the sound board. The trick is to make sure that the go-bars don't exert any side force that would force the braces to flip sideways. It's pretty much the same as using the go-bars to clamp 1/8" thick braces like those used on an A-brace top.

Edited by DanSavage 2017-02-09 12:30 AM

|

|

| |

|

Joined:

February 2016

Posts: 1882

Location: When?? | Dan.. and a whole other ponder on poly wood finishes. What bearing could the temperature of the wood and the liquid finish at the time of application have on how it holds up? Warm finish on cool wood.. cool finish on warm wood.. both cool.. both warm.. I would think that the proper mix of those combinations would be important to the longevity of a nice finish.

Edit again:: Man, as soon as I post a second question, you have already answered the first one! I've said it before, and again now.. you should host some occasional weekend seminars on this stuff where instant Q&A dialogue could take place. I'll gladly pay $100 to sign up for that (but you should have coffee and donuts, too).

Edited by Love O Fair 2017-02-09 12:55 AM

|

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | It's best is to have both the piece and the finish at the same temperature of no less than 65 degrees. Worst case is cold and damp. |

|

| |

|

Joined:

March 2002

Posts: 15679

Location: SoCal | Dan, is that picture of a current project?

|

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | moody, p.i. - 2017-02-09 7:27 PM

Dan, is that picture of a current project?

No. That's the 1717. I started cutting out the braces for the current project(s). I'll finish cutting the braces tomorrow and will start gluing them to the top(s) thereafter.

I'll be starting with your 1117 and Daren's 1528, followed by the 1612 and the 1778T. |

|

| |

|

Joined:

March 2002

Posts: 15679

Location: SoCal | Oh boy. Already this morning I was playing my 1537 and 1113. People, on the first guitar, Dan fixed structural problems and on the second, put a new top on. Both play and sound wonderful. West Coast Mothership? |

|

| |

|

Joined:

September 2005

Posts: 138

Location: Birmingham, AL | A little late to this but haven't been around for awhile. Never thought about the top distortion on my A braced 1119 made in 75 and my 1157 made in 1978. I've always used the 12-56 medium light strings with no issue. The tops have bellying behing the bridge and a little sinkng in front of the bridge but they are no worse than my other more "traditional" built guitars. Could go to lights I guess never thought about it. BTW I have owned these guitars since new.

Very interesting........

Edited by clrules 2018-04-28 8:33 PM

|

|

| |

|

Joined:

December 2013

Posts: 22

| Dan, you are spot on about the finish being the cause of the splitting. I just picked up a 1974 Balladeer 1111-6 that the bridge was lifting and in removing the bridge the finish started to come off as well. I took the rest off with the heat gun and the cracks flattened out and closed. I was in the automotive finish industry for over 25 years had to determine the causes of finish failure all the time and will back up your assessment 100% |

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | Thanks for the confirmation, Dennis. |

|

| |

|

Joined:

March 2002

Posts: 15679

Location: SoCal | As a follow up to Dan talking about light strings on a torrefied top, on my Dan Savage Legend (torrefied Addy spruce top and braces) I've gone to Martin Monal strings (nickle), mediums. The guitar sounds great and is handling the pull with no visible problems. |

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | Just a follow-up post.

Here's what the 1113 top looked like four years ago. (2017)

Here's what it looks like today.

As you can see the polyester finish continues to shrink. The amount of curl has increased significantly.

|

|

| |

|

Joined:

February 2016

Posts: 1882

Location: When?? | All of that from the contraction of finish. That is amazing. Give it one more year and it'll be a full-on cowboy hat! Was it on the wall the whole time, or laying flat? And does being so close to the beach shore like you are with periodic hour-to-hour-to-day fluctuation of humidity possibly help to accelerate it? |

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | Yep, just the finish shrinking.

Yes, it was hanging on the wall in the garage. Granted, we do park two cars in there, but on warm days we leave the garage door open after we park to allow the heat to escape.

We're about 4-5 miles from the actual shoreline. Where we live in California, the relative humidity remains pretty constant throughout the year.

Two things accelerate the shrinking: heat and UV. That's why it's bad to park your guitars anywhere near a window or any heat source.

Folks who keep their old Ovations in the case are going to experience the least amount of shrinking.

Edited by DanSavage 2021-07-02 6:35 PM

|

|

| |

|

Joined:

September 2005

Posts: 138

Location: Birmingham, AL | I've been working on my '81 1658 and I noticed that the top is domed all the way around. it's flat where the top is glued to the bowl and has a noticeable dome on it from there. verified with a ruler. The dome is in front of the soundhole as well as behind the bridge.

This guitar has very little top distortion when strung up and not a sign of a crack anywhere.

Didn't know that at some point the guitars were constructed that way.

|

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | To my knowledge, Ovations are true flat-top guitars.

Guitars like Martin, Taylor, etc., have 'domed' or radiused tops, but not Ovation.

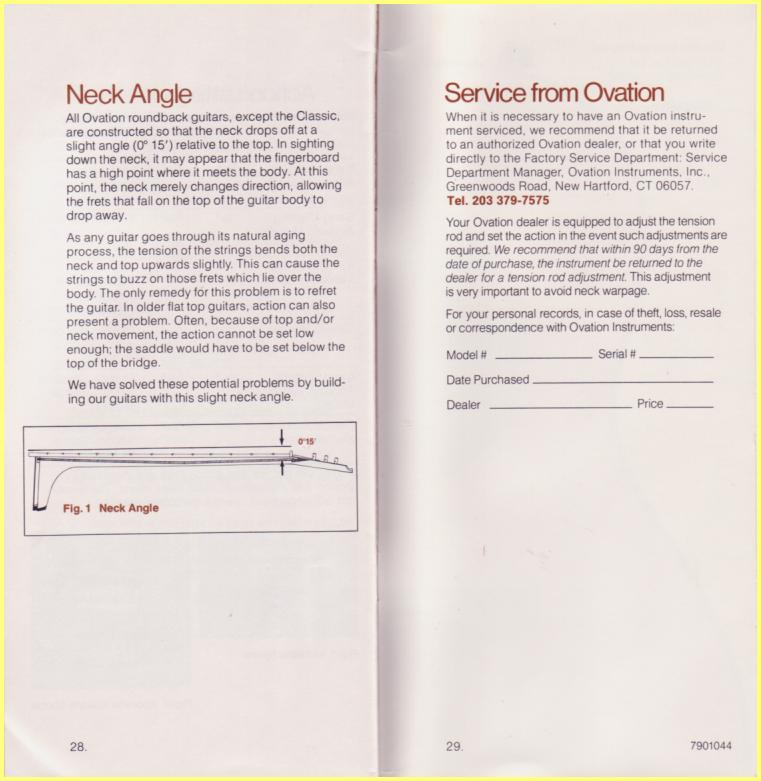

That's why the fretboard extension has a drop-off where it joins the body.

|

|

| |

|

Joined:

December 2008

Posts: 253

Location: Seattle | This is all very disturbing to me

……….Keeping watch on my beloved 72 legend.

Wonder if the textured guitars tops like the Elite1778-tx are going to have similar shrinkage/curl issues.

Edited by kentrookie 2021-09-23 11:56 PM

|

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | Although the Elite-T guitars still use polyester finish, it's much thinner than the gloss tops, so they shouldn't shrink as much.

That being said, no matter what the finish, it's always a good idea to keep guitars away from heat, cold, sunlight, etc. |

|

| |

Warped & Cracked Tops...

Warped & Cracked Tops... Warped & Cracked Tops...

Warped & Cracked Tops...