|

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | In addition to the 1974 1111, I'll be rebuilding a 1985 Legend at the same time

I was alerted to this guitar by a friend on FB. As luck would have it, the guitar was being sold in the condition shown here by a fellow living close by me, so I was able to pick it up in person rather than having it shipped.

Even though the guitar came with no top I was able to test the OP24 preamp by plugging the pickup on my 1617 into it. Overall, the finish on the neck is in good shape, so it won't need refinishing. The fret board is also in good shape, though the frets are very worn and will need to be replaced. I'll be using EVO gold frets. The tuners are also in good shape.

I'm going to use an ebony Custom Legend carved bridge with a black pickup instead of the usual white one, which should look pretty cool. It will get the standard pearloid rosette.

As I've said before I'm going to use torrefied Sitka spruce for the top and I'm going to use A-braces on this one. I've got two examples of an A-brace top. The first one came off a 1976 1619, which was an engineering example. The A-braces are pretty simple.

The cross brace in the middle of the A is not notched. The fan braces below this are simple 1/8" thick pieces of wood with a tapered scallop. The sides of the A were joined with a single piece of spruce forming a lap joint.

The second came off my 1617 and are quite a bit more complicated. The cross-piece is almost twice as thick and is notched for the fan braces. The fan braces are also more complex. The have the same tapered scallop, but they're also milled so the cross-section is like one half of an I-beam, with the wider part forming the base that is glued to the top wood. The ends of the fan braces also have a dap of epoxy securing them to the top wood, no doubt to keep them from popping up if the guitar is bumped. Instead of a single scrap of spruce lap-jointed to connect the upper and lower parts of the A braces, it's got a molded fiberglass reinforcement.

The braces I'm going to use on this guitar will be a hybrid of the two styles. I'll use the wider, notched cross-brace with the fiberglass reinforcements. The fan braces will have the tapered scalloped profile, but without the milled cross-section. I could make a tool to mill the wood, but I suspect the cross-section had more to do with reducing warranty work than with sound quality.

Edited by DanSavage 2016-09-25 4:34 PM

|

|

| |

|

Joined:

February 2014

Posts: 715

Location: moline,illinois | Very cool pics of the A-bracing and evolution over the years,do you have a CL bridge for this one or will you make your own? |

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | Thanks. I already have the bridge and the pick-up.

Interestingly, the finger braces and tone bars on the LX bracing used on my 50th Anniversary CL were also made with the same milled cross-section. Here's a couple of pics I took of the braces in my 2077AV50.

|

|

| |

|

Joined:

July 2013

Posts: 98

Location: Des Moines, Iowa | I've not really thought a lot about the bracing, though I've been aware of the different patterns and all. In looking at these two my initial un-educated thoughts are that the LX bracing would allow for more of the top to be free/open and possibly provide for a fuller or thicker tone? There's just not much room between the braces with the fan pattern, whereas the LX bracing provides for some larger unhindered surface area for the top. It would seem that the top would resonate a bit more with the LX because of this fact. Is any of this actually true?

Very interesting... maybe... |

|

| |

|

Joined:

December 2015

Posts: 287

Location: Katmandu | The 2077AV50 is so cleanly braced -- not a single drop of excess glue -- it puts a lot of other guitars to shame. When I checked out a Gibson LG1 (or LG2) by chance recently, I couldn't believe my eyes how poorly the bracing was glued to the top and back. |

|

| |

|

Joined:

February 2016

Posts: 1882

Location: When?? | I fully agree with Leonard... so incredibly clean... looks like something straight from the NASA white room. If that were my guitar I would print the photo and tuck it inside a thank you card mailed directly to the mother ship on behalf of those of us who admire their dedicated craftsmanship. I'm sure they'd all appreciate that. |

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | After I got the guitar, I sent a note to the MS complimenting them on the fit and finish of these anniversary guitars. IMO, they're as nice as anything I've seen.

|

|

| |

|

Joined:

October 2012

Posts: 1093

Location: Yokohama, Japan | DanSavage - 2016-10-03 1:50 AM

After I got the guitar, I sent a note to the MS complimenting them on the fit and finish of these anniversary guitars. IMO, they're as nice as anything I've seen.

Hi Dan! Looking forward to following your progress. What kind of mirror is that? Looks really useful! I want one! |

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | Hi Ken,

Thanks. I haven't been able to work on these guitars this week due to prior commitments, but I'm back on the job now.

That's the Stewmac 3-piece folding inspection mirror. http://www.stewmac.com/Luthier_Tools/Tools_by_Job/Tools_for_Inspect...

It's basically just three identical strips of mirrored plexiglass that are taped together so they z-fold into a strip that's narrow enough to fit through the sound hole. Once inside the guitar, you just unfold it. You could probably just make one yourself by going down to a local glass/mirror shop and having them cut three strips of mirrored plastic.

What I think is a really slick tool is their LED inspection light. It's got either 4 or 5 levels of brightness, is oct-shaped so it doesn't roll around, has built-in magnets and charges from a USB port or charger.

http://www.stewmac.com/Luthier_Tools/Tools_by_Job/Tools_for_Inspect...

Edited by DanSavage 2016-10-03 5:25 PM

|

|

| |

|

Joined:

May 2011

Posts: 760

Location: Muenster/Germany | The glue-drops at the end of the braces remind me to my old Gibson Mark guitar with the Kasha braces.

I learned from you a lot about the forward-shifted x.

Do you have any improvements for the classic A-braces in mind? I wouldn´t be surprised if your new topped "DS-A-BRACE" would easily blow off any other Legend Ovation... |

|

| |

|

Joined:

May 2011

Posts: 760

Location: Muenster/Germany | Another example of A-braces:

Custom legend 1769:

2. old custom legend 1619 (looks awful, sounds better)

|

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | DetlefMichel - 2016-10-06 8:55 AM

The glue-drops at the end of the braces remind me to my old Gibson Mark guitar with the Kasha braces.

I learned from you a lot about the forward-shifted x.

Do you have any improvements for the classic A-braces in mind? I wouldn´t be surprised if your new topped "DS-A-BRACE" would easily blow off any other Legend Ovation...

Except for using torrefied wood for the top and braces, I have nothing special planned for this. Since I don't have a way to mill scalloped cross-section, the fan braces will be like the early 1619. It will be a hybrid of the original 1619 and the later using the fiberglass reinforcements for the upper and lower A-braces and notched cross-brace, but with flat a-braces. As with all my guitars I will be using OBG to joint the halves and to glue the braces to the underside of the top. Not sure yet if I'm going to put glue-globs on the ends of the A-braces or not.

Yes, I'm really looking forward to hearing how a torrefied A-brace O sounds.

Edited by DanSavage 2016-10-06 12:02 PM

|

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | Thanks for the pics.

DetlefMichel - 2016-10-06 9:15 AM

Another example of A-braces:

Custom legend 1769: |

|

| |

|

Joined:

December 2015

Posts: 287

Location: Katmandu | Detlef's photos just reminded myself that I wanted to remove the bridge's screw nuts of my Legend entirely so that when the bridge someday does decide to come off the top it can do so freely and without ripping the well-aged top apart in the process.

Edited by leonardmccoy 2016-10-06 3:54 PM

|

|

| |

|

Joined:

May 2011

Posts: 760

Location: Muenster/Germany | Do you want to sell this guitar when it´s ready? |

|

| |

|

Joined:

May 2011

Posts: 760

Location: Muenster/Germany | I forgot to tell you that I meanwhile carefully fine-sanded the braces, I cannot live with such a mess, and see the real big hole in the top where the cables come out. It was so big that the low E string had barely material under it. The stereo pickup was broken anyway so I decided to transform the guitar into an acoustic.I filled the drilling hole with top-wood,

and made an exact matching piece of ebony to replace the pickup

and cut a nut for a bone saddle. and cut a nut for a bone saddle.

The guitar now sounds better than ever. The guitar now sounds better than ever.

But enough from me, now I`m eager to see upcoming sequels of your new guitar series, which I follow just like I did with "Breaking Bad"  |

|

| |

|

Joined:

March 2002

Posts: 15679

Location: SoCal | Looks very cool. How does it sound? Does the saddle go all the way down to the guitar top? |

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | DetlefMichel - 2016-10-07 8:14 AM

Do you want to sell this guitar when it´s ready?

In all fairness, it's already spoken for. But, if that buyer decides not to take it, you're second on the list.

I'm not going to name the buyer. If they choose to come forward, that's up to them. |

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | DetlefMichel - 2016-10-07 8:38 AM

I forgot to tell you that I meanwhile carefully fine-sanded the braces, I cannot live with such a mess, and see the real big hole in the top where the cables come out. It was so big that the low E string had barely material under it. The stereo pickup was broken anyway so I decided to transform the guitar into an acoustic.I filled the drilling hole with top-wood,

Nice job on the conversion. Yes, the stereo pick-up does need a rather large hole because of the size of the cables. |

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | I jointed the top wood for this guitar today. I've made an appointment with my sanding guy for Monday to thickness sand the top.

While the glue is drying I cut the brace stock. Here's the basic A-braces.

And here's what it looks like compared to the original braces. The angles on the fan braces are approximate. I'll measure them for exact angles once the top is thickness sanded the top and cut out the outline and the sound hole.

Here's the aluminum A-brace reinforcements. The braces will be glued to the top wood using OBG, and the reinforcements will be glued using epoxy.

|

|

| |

|

Joined:

February 2014

Posts: 715

Location: moline,illinois | Very cool work as usual,if you tried to adapt the A-bracing to a 12 string would you add an extra cross brace by the bridge to support the extra tension.I've always wanted an A-braced Custom Legend 12 string and have been on the lookout for parts to create one. |

|

| |

|

Joined:

October 2012

Posts: 1093

Location: Yokohama, Japan | Hi Dan! Thanks for sharing another very very cool project. Hope you don't mind a few questions...How thick are the aluminum reinforcements and did you perforate them yourself? Will you fine tune the bracing with your chisel after you mount them to the sound board or are they pretty much in their final condition? Really enjoyable stuff! |

|

| |

|

Joined:

December 2004

Posts: 578

Location: Denmark | Aluminum pieces are angled and glued to the outfacing sides of the bracing, I suppose. Apparently the ADII uses Alu reinforcements with varying success. http://www.ovationfanclub.com/megabbs/forums/thread-view.asp?tid=44...

Edited by tpa 2016-10-08 6:59 AM

|

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | 2wheeldrummer - 2016-10-07 8:31 PM

Very cool work as usual,if you tried to adapt the A-bracing to a 12 string would you add an extra cross brace by the bridge to support the extra tension.I've always wanted an A-braced Custom Legend 12 string and have been on the lookout for parts to create one.

Thanks, Kevin.

I never really thought about what changes would be made for an A-brace 12-string. I don't think an extra cross-brace at the bridge would do much to prevent bellying. Maybe just make these fan braces taller in cross-section.

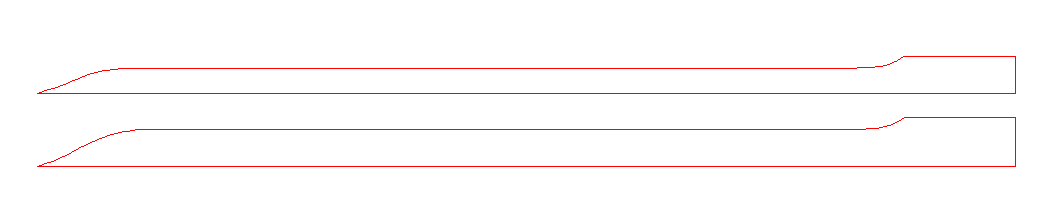

Here's a drawing that shows what changes I would make. The top brace is the A-brace pattern I used. The bottom one is what I would use if I were to make an A-brace 12-string. The tallest part of the upper brace is 3/8" and tapers down to 1/4". The tallest part of the lower brace is 1/2" and tapers down to 3/8".I would also make all of the other brace wood 1/2" thick instead of the 3/8" it is now.

A while ago I read the patent description for Adamas quintaid bracing pattern. One of the things I remember is the description of how a guitar top vibrates. Basically, it twists in torsion. The quintaid braces allow more twisting and the lack of a center sound hole prevents the top from warping due to string tension. The A-brace looks to me, like a quintaid brace pattern that allows for a center sound hole. It seems to me that using taller braces that are still 1/8" thick, like the fan braces would help prevent the top from warping due to extra string tension, but still allow it to twist.

Edited by DanSavage 2016-10-08 10:09 AM

|

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | arumako - 2016-10-07 9:08 PM

Hi Dan! Thanks for sharing another very very cool project. Hope you don't mind a few questions...How thick are the aluminum reinforcements and did you perforate them yourself? Will you fine tune the bracing with your chisel after you mount them to the sound board or are they pretty much in their final condition? Really enjoyable stuff!

Thanks, Ken.

The aluminum braces are 1/32" thick. (.032" or .8mm)

Nope. These came from the MS just as you see them. The braces are in their final configuration. These are pretty close approximations of the fan braces you see on the sound board to the left. |

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO |

Yeah, gluing metal, like these aluminum pieces to wood can be tricky. The purpose of the perforations is to give the glue something to grab onto. But, in order to work properly, you need to use enough glue so that it squeezes through all the holes. This is one application where more glue is better. The best bet is to have the glue ooze out through every hole. To maximize the holding power, I'm also going to sand the underside of these pieces to rough them up. Naturally, I'll be using Hysol.

Looking at the pics in the thread above tells me two things: too little glue in areas and the aluminum wasn't roughed up before being glued down.

Edited by DanSavage 2016-10-08 10:20 AM

|

|

| |

|

Joined:

December 2004

Posts: 578

Location: Denmark | ... or chamfer (some of) the holes on the free edge to provide an epoxy-rivet-head effect. |

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | Yes, that would work, too. Hysol is strong enough that you wouldn't even really need the holes. Just roughing up the underside of the aluminum would give it enough tooth that the brace stock would split long before the aluminum pulled away from the glue joint.

Edited by DanSavage 2016-10-08 6:27 PM

|

|

| |

|

Joined:

May 2011

Posts: 760

Location: Muenster/Germany | moody, p.i. - 2016-10-07 6:41 PM

Looks very cool. How does it sound? Does the saddle go all the way down to the guitar top?

No, the ebony is one piece that fits with very low clearance in the bridge, and the countersink (I don´t know to say that in english) for the bone saddle is about 5mm deep. It may be an illusion but I did it with 2 of my old Ovation guitars and they sound much better now, epecially more lower midrange and overall more intensity. I had even better results when I made the saddle of brass with some drilling holes for less weight.

|

|

| |

|

Joined:

May 2011

Posts: 760

Location: Muenster/Germany | DanSavage - 2016-10-08 4:57 AM

The angles on the fan braces are approximate. I'll measure them for exact angles once the top is thickness sanded the top and cut out the outline a

The original fan braces are quite symmetrical. Wouldn´t it be better to break the symmetry? To open the 4 braces on the bass side a bit? |

|

| |

|

Joined:

May 2011

Posts: 760

Location: Muenster/Germany | DanSavage - 2016-10-08 5:08 PM The A-brace looks to me, like a quintaid brace pattern that allows for a center sound hole. It seems to me that using taller braces that are still 1/8" thick, like the fan braces would help prevent the top from warping due to extra string tension, but still allow it to twist.

That´s right. I have a custom-made 12string guitar with fan-braces and only one (warped) cross-brace, no problems with the top but grrreeeaaat sound. Too many cross-braces like the ones in the customlegend 12strings might be soundkillers.I only have a pic of the braces in the raw, but you see that´s all you need for a 12string. The finished braces are even a lot finer.

|

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | DetlefMichel - 2016-10-10 9:43 AM

The original fan braces are quite symmetrical. Wouldn´t it be better to break the symmetry? To open the 4 braces on the bass side a bit?

That's interesting. I didn't really look at the pattern of the fan braces in the pics you posted earlier, but the braces on your CLs are different than mine.

Here's your 1619. The braces look parallel to each other and look evenly spaced.

Here are the braces on mine. The one on the left came off my 1976 1619. This was the factory engineering guitar. The one on the right came off my 1978 1617. There are several refinements to the 1617 braces, themselves, but the pattern of the fan braces are nearly identical to each other.

As you can see, they are not parallel. Also, they are not evenly spaced from each other. At the top where they meet the cross-brace, they are spaced from left to right: .625", .75", .75", .6875, .875", .875". (15.9mm, 19mm, 19mm, 17.5mm, 22.2mm, 22.2mm) At the bottom, they measure from left to right, 1.125", 1", 1.375", 1", 1", 1". (32mm, 25.4mm, 35mm, 25.4mm, 25.4mm, 25.4mm) Like I say, the two sets of braces from these two guitars measure pretty close to the same distances, top and bottom. Since they were built two years apart, I don't think the spacing was accidental. But, it's interesting that the braces on your guitars look parallel. I wonder if it's an optical illusion from how close the camera is to the cross brace. |

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | Yep. It's an optical illusion. Here's a pic I took of my braces that matches the angle and location of your pics.

As you can see, they look parallel even though we know they aren't. So, that means that your CLs also have this same asymmetrical pattern on the fan braces.

|

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | DetlefMichel - 2016-10-10 10:07 AM That´s right. I have a custom-made 12string guitar with fan-braces and only one (warped) cross-brace, no problems with the top but grrreeeaaat sound. Too many cross-braces like the ones in the customlegend 12strings might be soundkillers.I only have a pic of the braces in the raw, but you see that´s all you need for a 12string. The finished braces are even a lot finer. Nice guitar. |

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | Back to building.

I was able to get the top wood thickness sanded. I also cut out the basic outline and drilled the holes for the bridge locating pins. I checked the neck angle and it's plenty good and won't need a neck reset. (Yay!)

I cut the sound hole and fitted the rosette.

Next job is to lay out the braces on the underside of the top and start gluing them down. |

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | Normally I would wait to drill the hole for the pick-up wire until after the top is glued to the bowl, but because of the spacing of the fan braces I decided it would be best to do it now. This will be a cool-looking guitar. It's going to have an ebony CL bridge with a black pickup and a pearloid rosette.

Brace pattern is laid out on the underside of the top.

I used the 1619 top I had to confirm the brace pattern was correct. The mis-alignment seen in the pic below is due to parallax.

Braces glued, waiting to dry. I'll glue the aluminum reinforcements tomorrow after the OBG has dried.

|

|

| |

|

Joined:

October 2012

Posts: 1093

Location: Yokohama, Japan | Just...fantastic Dan! Sorry about all the questions, but what kind of material (black colored sheet) are you using under the sound board? My '94 1861-4 has X-bracing, my son's '00 1861-5 has A-bracing (both SSBs). The X-braced 1861 is louder and more dynamic. The A-braced 1861 is tighter with a consistent dynamic range across the fret board. Are you shooting for the consistent dynamic range with the A-brace or does the deep bowl configuration bring completely different acoustic characteristics into play?

...and I see you're 1619 was sold to a happy happy dnc4eva. Pretty soon people are going to be knocking down your doors to get their Dan Savage rebuilt vintage O! When I go to see my son at college, I might be one of those guys lined up outside! LOL! Just awesome work!

Edited by arumako 2016-10-10 10:31 PM

|

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | Hi Ken,

The black material is a section of a trash bag. I ran out of visqueen, so the black trash bag was the largest single piece of plastic I had on hand.

Yes, the X-brace will be louder than the A-brace. A friend of mine is a professional recording musician and he says that the engineers always want him to bring his A-braced Ovation to the recording sessions. He says it's because they don't have to adjust the levels to soften the strong bass response of other guitars, such as those using the X-brace pattern.

Yes, I'm doing an A-brace, partly because I'm curious what it will sound like using torrefied wood, and also because the A-brace is one of the most popular patterns among O fans.

Personally, I'm a fan of the X-brace, in general, and specifically, the simple X-braces used on the original 1960s Balladeers. It sounds really good, and are really easy to make. The X-braces used on the 1974 1111 I'm rebuilding are similar, but are tapered on the upper part of the X and have the three tone bars between the lower part. It still sounds every bit as good as Ovation's original X-braces. |

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | Aluminum reinforcements glued into place.

|

|

| |

|

Joined:

May 2011

Posts: 760

Location: Muenster/Germany | arumako - 2016-10-11 5:29 AM

Pretty soon people are going to be knocking down your doors to get their Dan Savage rebuilt vintage O!

Arumako you are so right!

What a wonderful piece of spruce! And the looks of the dark CL bridge and the light rosette will be the "Hammer" as we say in german. 6-string Mercedes 560 SEC. This is going to be a "one of 1000" guitar.

... And thank you for your patience with all our comments and questions. |

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | Thanks, guys.

Yes, I agree with you. The grain and silking on this top will be very similar to Jay's 1967 Balladeer. I like the how the ebony bridge looks with the pearloid rosette. I did the same thing on my 1617, but the black saddle and wood carving adds just a little bit extra flair. This will also be getting gold EVO frets and gold strap buttons to match the gold tuners. It will look every bit as good as it sounds. |

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | Top being glued to bowl.

|

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | The glue joint between the top and bowl was cured enough that I was able to pull the weights off.

I used some of epoxy I mixed up for the fretboard extension of the 1111 to glue the binding that popped off the end of this fretboard extension.

I'll let the top/bowl glue joint cure until this afternoon, then I'll grind down the excess top material in preparation for routing the binding and purfling channels. |

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | Top is glued and out of the clamping fixture.

I routed the binding and purfling channels.

And, glued the binding and purfling into place. I'll let the glue dry until tomorrow, then pull tape and start scraping.

|

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | Binding tape pulled up.

Binding and purfling scraped down. The top is ready for finishing. But, while I work on the headstock repair and finishing the neck on the 1111-4, I'll refret this guitar's neck with EVO gold frets.

|

|

| |

|

Joined:

June 2012

Posts: 2345

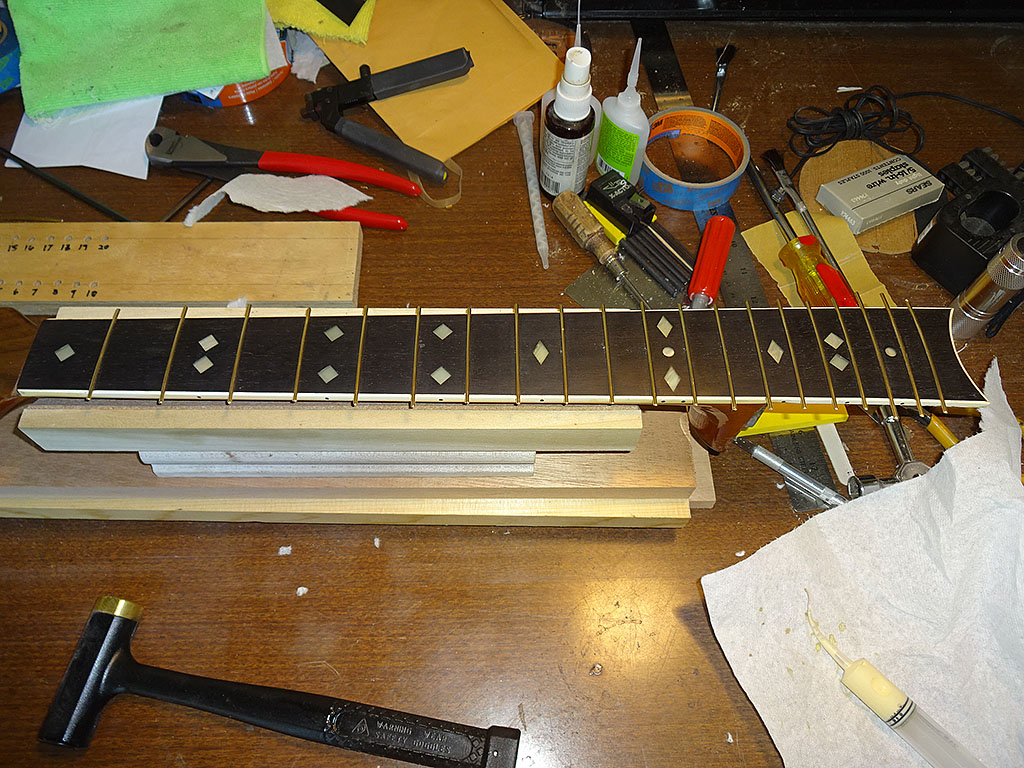

Location: Pueblo West, CO | Old frets are out, slots cleaned. New frets cut, tangs trimmed, ready for installation.

New frets are installed. I'll let the glue dry until tomorrow, then trim and bevel the ends. After that, they'll be ready for leveling and crowning.

|

|

| |

|

Joined:

March 2002

Posts: 15679

Location: SoCal | Can't wait to play these puppies.....

Assuming I'm allowed. |

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | Me, too. Not just allowed, but encouraged.

Yeah, I already have a good idea of what the 1111-4 is going to sound like because of how Jay's guitar sounds.

I'm curious what this one will sound like. No one's ever heard a torrefied-top A-brace O before. |

|

| |

|

Joined:

May 2008

Posts: 1565

Location: Indiana | As you probably know, Paul and I are huge fans of A-braced O's. Bet he's salivating. I would be.

Again, beautiful work Dan. |

|

| |

|

Joined:

January 2009

Posts: 1249

Location: Texas | Dan, I dont think it will exceed 485 in acoustic response...I just cannot see how that is possible. I am not sure if you remember, but we talked briefly about going the A route, but you convinced me otherwise....and I am glad you did. How much difference will the bowls play, do you think? |

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | Hi Jay!

You're not making it easy for me here. LOL!

I think you are correct. The addition of the tone bars on the 1111-4 will limit the response to a certain respect. There's no doubt in my mind that the original simple x-brace top, along with the hand-laid, vacuum-bagged, male-mold bowls, such as #485, are the best that Ovation produced.

But, based upon my playing of the guitar, the response of the 1111-4 is still pretty darned respectable, even though it is a 2nd gen hand-laid bowl.

WRT to bowl technologies, IMO, the thinner the fiberglass, the better. But, in all fairness, a good lay-up man can produce a hand-lay-up that is as good (minimal resin) as a vacuum-bagged setup. So, in terms of the amount of resin used, I'm seeing that the 1111-4 I'm rebuilding has as good of a lay-up as #485.

Now, the A-brace is a different animal entirely from the X-brace guitars and should not be compared with the original X-brace guitars. As I understand it, the 1960s X-brace guitars were pitted head-to-head against the Martin HD-28 Brazilian rosewood guitars and they succeeded, as you know from playing #485.

The A-brace was an attempt to mellow the strong bass response of the X-brace to produce a more balanced response from bass to treble.

In the end, it'll be interesting to compare this guitar to 1111-4.

jay - 2016-10-20 5:25 PM

Dan, I dont think it will exceed 485 in acoustic response...I just cannot see how that is possible. I am not sure if you remember, but we talked briefly about going the A route, but you convinced me otherwise....and I am glad you did. How much difference will the bowls play, do you think? |

|

| |

|

Joined:

March 2002

Posts: 15679

Location: SoCal | Jonmark Stone - 2016-10-20 4:28 PM

As you probably know, Paul and I are huge fans of A-braced O's. Bet he's salivating. I would be.

Again, beautiful work Dan.

Uh, that would be big yup I'm.... |

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | moody, p.i. - 2016-10-20 7:40 PM

Uh, that would be big yup I'm....

Wel,, Paul, when I'm ready, you'll have to make sure to make enough time to try out, not only the 1717-4. the 1111-4, but also the 2077-AV50. :D |

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | New frets are done. I'm going to set this neck aside for the time being while I concentrate on fixing the 1111-4 headstock.

|

|

| |

|

Joined:

March 2002

Posts: 15679

Location: SoCal | Cool! |

|

| |

|

Joined:

February 2014

Posts: 715

Location: moline,illinois | DanSavage - 2016-10-20 10:00 PM

moody, p.i. - 2016-10-20 7:40 PM

Uh, that would be big yup I'm....

Wel,, Paul, when I'm ready, you'll have to make sure to make enough time to try out, not only the 1717-4. the 1111-4, but also the 2077-AV50. :D

You'll have to post some audio samples for all of us to drool over,I'm a big A-brace fan and would love to hear how it compares to the newest 20077-AV50 as well as to the traditional balladeer tone,Please and ThankYou!!!

|

|

| |

|

Joined:

October 2012

Posts: 1093

Location: Yokohama, Japan | DanSavage - 2016-10-21 4:36 AM New frets are done. I'm going to set this neck aside for the time being while I concentrate on fixing the 1111-4 headstock. Incredible! So, a question from "Ignorant Arumako" over here...you pulled the frets withOUT removing the binding first? How did you ever do that without breaking the binding? Some kind of heat to soften things up or do you have some kind of mystical feather touch when pulling frets? Or is this standard procedure?

Edited by arumako 2016-10-21 9:10 PM

|

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | 2wheeldrummer - 2016-10-21 3:15 PM

You'll have to post some audio samples for all of us to drool over,I'm a big A-brace fan and would love to hear how it compares to the newest 20077-AV50 as well as to the traditional balladeer tone,Please and ThankYou!!!

I'm sure I can post something.  |

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | arumako - 2016-10-21 7:04 PM Incredible! So, a question from "Ignorant Arumako" over here...you pulled the frets withOUT removing the binding first? How did you ever do that without breaking the binding? Some kind of heat to soften things up or do you have some kind of mystical feather touch when pulling frets? Or is this standard procedure?

Hi Ken!

Yes. Re-fretting doesn't require pulling the binding. During the manufacturing process, the slots are cut into the fingerboard first, and run all the way through. Then, the fingerboard binding is added. (SOP)FlySig posted a BFLG thread that details the basic steps I went through. (See: EVO Gold frets on a Deacon) He also posted a step-by-step tutorial. (See: A beginners guide to re-fretting your guitar) But, to answer your question, I heated up the fret using a soldering iron to soften the glue, then carefully pulled the frets up a little bit at a time. (See: Removing the frets on the Mike Bloomfield Tele) Basically, yes, you have to be patient and let the heat of the soldering iron do the work. Once the glue softens, the frets come out pretty easy with the fret puller. Dan

Edited by DanSavage 2016-10-22 11:28 AM

|

|

| |

|

Joined:

February 2016

Posts: 1882

Location: When?? | Dan.. thanks for posting those links. I checked them out (great tutorial, FlySig!) and it fully re-affirms to me that I may as well have hooves instead of fingers since at the current point on my BFLG learning ladder I would SO mess this stuff up; hence, I am thankful for cheap yard sale guitars because I will have to go through a stack of them before I would dare try re-fretting anything I love and cherish. So in the meantime I am also very thankful that you guys exist and there are roads and streets leading to your shops! |

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | I decided to start finishing the top on this guitar while I'm finishing the neck of the 1111-4. Here's the first sealer coats of clear. It's a nice looking piece of spruce that has lots of silking and character.

|

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | Top finishing is all done and polished.

Bridge masking removed.

Bridge being glued down.

Bridge masking removed while glue continues to cure.

Neck aligned and mounted. Waiting for fret board extension glue to cure. Then, it's time to glue rosette.

Edited by DanSavage 2016-11-21 8:53 AM

|

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | Rosette is mounted.

|

|

| |

|

Joined:

February 2014

Posts: 715

Location: moline,illinois | She's becoming a real beauty,love that carved bridge. |

|

| |

|

Joined:

September 2012

Posts: 815

Location: Thredbo, NSW, Australia | Looking good Dan! When do the strings go on?

|

|

| |

|

Joined:

May 2011

Posts: 760

Location: Muenster/Germany | Wonderful. A dream guitar. Too bad it has the * ugly * blue Ovation sticker inside (sorry, boys, but I never could understand that they replaced the metal labels. Ovation guitars were horribly expensive at that time and how much can a label cost? Makes the guitar look cheap).

|

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | Thanks, guys. It's actually even better looking in person.

BanjoJ - 2016-11-21 6:09 PM

Looking good Dan! When do the strings go on?

Probably sometime today, actually. I need to mount the hardware, then make a nut, string it up and set the action. |

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | All done. I will say that it sounds every bit as good as it looks.

|

|

| |

|

Joined:

December 2003

Posts: 855

Location: Canada | Wow she's gorgeous! Congrats on another great project completion. I hope we will get some sound samples as well. |

|

| |

|

Joined:

March 2002

Posts: 15679

Location: SoCal | Beautiful. I need to come over this weekend, return your movie, and give this Legend a spin....

|

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | d'ovation - 2016-11-23 10:49 AM

Wow she's gorgeous! Congrats on another great project completion. I hope we will get some sound samples as well.

Thanks.

Yes, once I get the 1111-4 done, I'll record it and this one and maybe the 50th CL, too. Nothing fancy. Just my video camera. |

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | moody, p.i. - 2016-11-23 11:14 AM

Beautiful. I need to come over this weekend, return your movie, and give this Legend a spin....

The bambina, she's ah-all tuned up and ah-waiting for you.  |

|

| |

|

Joined:

March 2002

Posts: 15679

Location: SoCal | It ought to sound as good if not better than any 1970's-80's A braced Legend. |

|

| |

|

Joined:

February 2014

Posts: 715

Location: moline,illinois | Absolutely gorgeous,I love the way the black saddle goes with the bridge. |

|

| |

|

Joined:

February 2016

Posts: 1882

Location: When?? | In awe. Absolute awe. Dan, you are a wizard! (and then some) |

|

| |

|

Joined:

May 2011

Posts: 760

Location: Muenster/Germany | Chapeau! 6-string Winchester 73.

(I would use ebony tuner knobs.)

And...what do you think about the A-braced guitar if you compare it with a forward-shifted X? |

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | moody, p.i. - 2016-11-23 6:02 PM

It ought to sound as good if not better than any 1970's-80's A braced Legend.

It does sound pretty darned good. It's the best sounding A-brace I've had the pleasure of playing. Tons of sustain. It's like a standard A-brace on steroids. More of everything that makes an A-brace sound like it does.

The carved ebony bridge is noticeably heavier, so it does tend to dampen the high frequency response a little. But with a slight adjustment in attack on the high strings, the sound comes back into balance. Once you play it, you'll understand what I mean. |

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | 2wheeldrummer - 2016-11-23 6:26 PM

Absolutely gorgeous,I love the way the black saddle goes with the bridge.

Thanks, Kevin. Me, too. |

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | Love O Fair - 2016-11-23 6:53 PM

In awe. Absolute awe. Dan, you are a wizard! (and then some)

Thanks, Al. I appreciate the kind words. It's not without its flaws, but it's still a very pretty looking and great sounding guitar. |

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | DetlefMichel - 2016-11-24 3:18 AM

Chapeau! 6-string Winchester 73.

(I would use ebony tuner knobs.)

And...what do you think about the A-braced guitar if you compare it with a forward-shifted X?

Yep. It's definitely a very unique guitar.

A-brace vs. forward X-brace? Personally, I still prefer the X-brace sound. This guitar sounds very good, and if I were to own an A-brace guitar, this would be the one for me. As I wrote to Paul, it's like a A-brace on steroids. More of everything that makes an A-brace sound like it does.

As good as it sounds, I think it might sound a little more lively with a lighter weight walnut bridge as the ebony bridge seems to be dampening the high frequency response a little. This minor shortcoming is easy to compensate for with a slight adjustment to playing style.

I tried PB strings and wasn't that impressed. I changed the strings to 80/20s and I like the sound a lot better.

Yes, it probably would look good with ebony knobs on the tuners. |

|

| |

|

Joined:

May 2011

Posts: 760

Location: Muenster/Germany | Could this be the reason why my Adamas 1687-91 red sounds a little "higher"than my 1687-91 black? The black was buit just 2 years later, but it appears to have an other piece of wood used for the bridge, very much darker.I wondered how this could be with the same strings and the same setup. |

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | It could be. |

|

| |

|

Joined:

October 2012

Posts: 1093

Location: Yokohama, Japan | DanSavage - 2016-11-23 2:26 AM

All done. I will say that it sounds every bit as good as it looks.

Saw this a couple of hours ago, and just getting a hold of myself...just in speechless blissful agony...she looks absolutely divine, Dan...but sounds "that" good? My heart might shutdown if I hear her sing...your killing me!

On a more pacific note, I've begun my first fret job! Was successful in removing the frets from a Yamaha CPX-10 that needs some urgent care. Your soldering iron tip worked like a charm! Thanks for the inspiration!

Edited by arumako 2016-11-24 9:37 PM

|

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | Hi Ken,

Thanks for the kind words. When I get the 1111-4 done, I'll make clips of each one so you can hear for yourself how this one sounds. (make sure to have a defibrillator handy before clicking 'play' - LOL!)

Kewl! Yeah, frets seem scary at first, but once you start in on the job, they're actually kind of fun and easy. |

|

| |

|

Joined:

February 2016

Posts: 1882

Location: When?? | I can't stop coming back to look at the grain on the top. You said earlier that is has character, and I have to fully agree. I don't recall ever seeing anything quite like that... longs and shorts running 90 degrees to each other in perfect little stacks like heat sink fins on a radiator-- thousands of 'em. Either I've lived a wood-grain-sheltered life, or that was the unique tree in the grove (I'll go with the latter). |

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | Love O Fair - 2016-11-25 7:27 PM

I can't stop coming back to look at the grain on the top. You said earlier that is has character, and I have to fully agree. I don't recall ever seeing anything quite like that... longs and shorts running 90 degrees to each other in perfect little stacks like heat sink fins on a radiator-- thousands of 'em. Either I've lived a wood-grain-sheltered life, or that was the unique tree in the grove (I'll go with the latter).

Yes. The 'shorts' as you describe them which are running 90 degrees to the grain is known as 'silking' and is usually an indication of wood that is perfectly quarter-sawn.

The 'silking' is easier to see on torrefied wood because the process makes that part of the grain stand out.

|

|

| |

|

Joined:

December 2004

Posts: 578

Location: Denmark | DanSavage - 2016-11-22 7:26 PM

All done. I will say that it sounds every bit as good as it looks.

Besides mastering lutherie You have good sense for tastefully presenting the final result. One thing that catches the eye with these old guitars is the images reflected by the top telling that the bellies on these old buddies are really flat. |

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | Thanks for the kind words.

The bellies are really flat right now.

One of the reasons why I like to use extra light strings is that it helps keep the top from bellying long into the future. Though, this guitar is strung with 80/20 lights.

tpa - 2016-11-30 9:30 AM

Besides mastering lutherie You have good sense for tastefully presenting the final result. One thing that catches the eye with these old guitars is the images reflected by the top telling that the bellies on these old buddies are really flat. |

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | Here's a family portrait of the two stable-mates. Yes, the top on the 1717 is noticeably darker than the 1111. Weird because both tops were bought at the same time, though it's obvious, to me, at least, that both were not in the same batch during the torrefaction process. It's clear that the 1717 is more 'well done.'

Edited by DanSavage 2016-12-01 6:27 PM

|

|

| |

|

Joined:

January 2009

Posts: 1249

Location: Texas | Gosh Dan...those are beautiful. Thank you for continuing to do these threads. Kind of wierd that your tops have such a different personality. I wish we could put up 485 beside them. Pat yourself on the back. |

|

| |

|

Joined:

October 2012

Posts: 1093

Location: Yokohama, Japan | Torreifed A-braced Legend and torrefied forward X-braced Balladeer! With the same quality tops, the bracing comparison should really stand out clearly. Stare at this picture long enough and I swear, I can hear them singing! |

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | jay - 2016-12-01 8:28 PM

Gosh Dan...those are beautiful. Thank you for continuing to do these threads. Kind of wierd that your tops have such a different personality. I wish we could put up 485 beside them. Pat yourself on the back.

Thanks, Jay.

The 1717 is pretty close to 485 in coloring and grain pattern. |

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | arumako - 2016-12-02 5:52 AM

Torreifed A-braced Legend and torrefied forward X-braced Balladeer! With the same quality tops, the bracing comparison should really stand out clearly. Stare at this picture long enough and I swear, I can hear them singing!

Thanks, Ken.

FWIW, the Balladeer using the 2nd generation of Ovation's original X-brace. This pattern is similar to that seen on Jay's 1967 Balladeer except that they tapered the upper part of the X and added the tone bars between the lower part. And, of course, there's no fiberglass strip laminated between the lower legs of the X.

Personally, I really like the lining Ovation used on these guitars. They would have a similar effect to the suspension ring used on the Adamas. |

|

| |

|

Joined:

August 2016

Posts: 61

| Wow, absolutely gorgeous. I have to keep wiping off my keyboard from salivating. Great work Dan. |

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | Thanks, Rick.  |

|

| |

|

Joined:

March 2002

Posts: 15679

Location: SoCal | I was able to play both these guitars, as well as Dan's 50th Custom Legend. Both the CL and the Balladeer had extra light strings on them which are Dan's preferred strings. They don't do much for me, but it was enough to let me know that both guitars were steller.

The Legend had light gauge Elixir 80/20's (nano). That guitar made me stop and play for a while. That guitar was steller. It sounded more like a really good dreadnaught than an A braced Legend (most Ovations are more like OM guitars to my ear). It was wonderful. I own an A braced Legend and it does not sound like this guitar. My Legend is a 1977 and originally, it sounded like crap. I had a new body (A braced) put on the old neck about 8 years ago. Much much much better guitar.

But the torrefied top put Dan's Legend into a whole different catagory. I don't have the money to spend right now, but the thought of taking my rebuilt Legend and having Dan pull off the top and put on a torrefied Addirondack spruce top and braces on it keeps bouncing around in my head.

A man can dream, can't he?

Edited by moody, p.i. 2016-12-05 12:06 PM

|

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | Hi Paul,

It was great to see you again, yesterday. It was equally great to be able to hear the guitars from the front instead of from behind them.

I agree. All three guitars sounded really good. It's funny. I could really see the gears turning in your head about having me re-top your Legend. If you decide to ever do that, I'll give you the same good-guy discount that you got on your 1113. :D |

|

| |

|

Joined:

March 2002

Posts: 15679

Location: SoCal | Oh my. I gotta think about that one........ |

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | Yeah. Now that you know how good a torrefied Sitka spruce A-brace guitar sounds, imagine how an Adi A-brace O would sound. (LOL - No pressure or anything...)

Actually, that would be an interesting experiment, no?

Edited by DanSavage 2016-12-05 10:14 PM

|

|

| |

|

Joined:

February 2014

Posts: 715

Location: moline,illinois | DanSavage - 2016-12-05 10:12 PM

Yeah. Now that you know how good a torrefied Sitka spruce A-brace guitar sounds, imagine how an Adi A-brace O would sound. (LOL - No pressure or anything...)

Actually, that would be an interesting experiment, no?

Besides the cutaway bowl how much do you think an Adi would differ from your torrefied legend,you already have the carved ebony bridge,is there torrefied AAA spruce you could use for the top,the thought of that is awesome.

I have a 1667 deep bowl cutaway with a cracked up top I would donate for that project. |

|

| |

|

Joined:

March 2002

Posts: 15679

Location: SoCal | DanSavage - 2016-12-0512 PM

Yeah. Now that you know how good a torrefied Sitka spruce A-brace guitar sounds, imagine how an Adi A-brace O would sound. (LOL - No pressure or anything...)

Actually, that would be an interesting experiment, no?

That's what I was thinking. Lets talk about this after the first of the year. |

|

| |

|

Joined:

July 2014

Posts: 154

Location: Canberra, Australia | For the record, I'd be seriously interested in hearing how a torrified cedar top would sound... |

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | Eynowd - 2016-12-06 5:04 PM

For the record, I'd be seriously interested in hearing how a torrified cedar top would sound...

Unfortunately, no one torrefies cedar. Or, at least to my knowledge, not yet.

As an aside, I did shoot some video of Paul playing the 1717, 1111 and the 2077-AV50. I'll process the video and post it in the next few days. |

|

| |

1985 1717 Legend Rebuild...

1985 1717 Legend Rebuild... 1985 1717 Legend Rebuild...

1985 1717 Legend Rebuild...