|

|

Joined:

October 2012

Posts: 1093

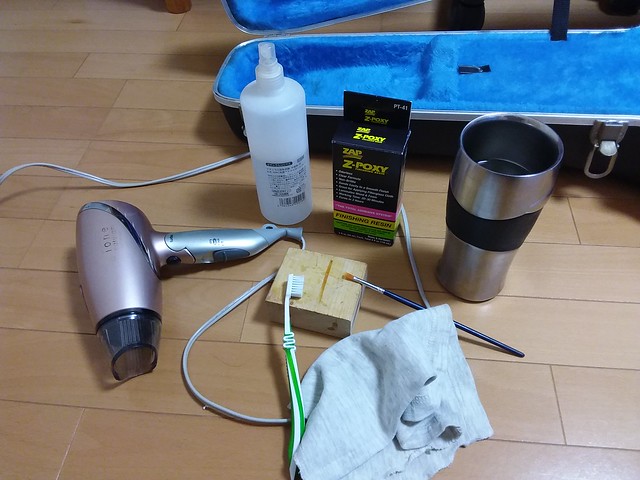

Location: Yokohama, Japan | So... I won an auction for a 1990 Elite 1868; but because of my own careless biding, I ended up paying more than I had bargained for. The 1868 arrived today with a multitude of issues. I'm hoping that sharing here, might garner some discussion and much needed advice (for me) from the experienced BFLG members. I'm also hoping that documenting this might help others dealing with similar issues. Of course, sending the guitar to the Mini-Mother would be the most wise and obvious choice, but I know the repairs alone would cost more than the guitar not to mention round trip shipping costs from Japan to New Hartford! So...I took off all the hardware to get started...

This 1868 was dropped some years ago, splitting the bowl from the top. The previous owner attempted to epoxy the top and bowl back together on several occassions leaving an enormous amount of epoxy build up all over the place. I cleaned up the old epoxy build up first, and it looks like I've got my work cut out for me...

Eventually, the previous owner just stuck this poor thing in her case and left it there for several years. It looks like the string tension has permanently changed the shape of the top. It takes quite a bit of force to push the top back down into position. I'm thinking Z-Poxy will get the adhesive job done, but I'm wondering if I need to flatten the top back down somehow before glueing?

Another big challenge is the chipped clear coat near the edge of the binding. Once I glue the top back down, I'm going to have to find a way to fill in these cracks. I think thin ZAP CA's capillary action will fill-in the areas of the clear coat that is pulling away from the top, but I think I'm going to need to add some kind of polyurethane filler to fill-up the gapping cracks and holes. A lot of sanding and filling to keep it smooth. It's really interesting how the original clear coat has yellowed like vintage instruments often do. That will obviously be impossible to match.

Years of neglect in the case made the foam on the manhole cover brittle so I just removed it. I'll need to cut out some foam with the right density to get the manhole cover back into shape...

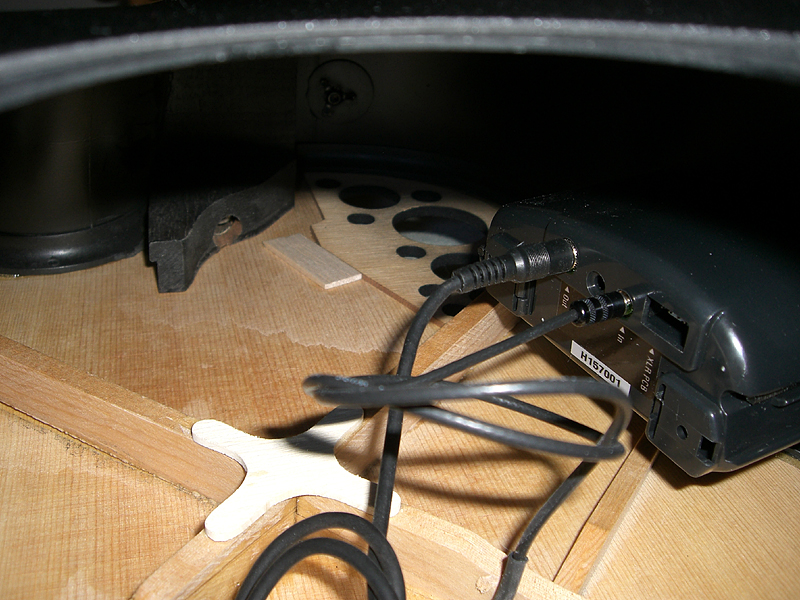

One of the really surprising things about this guitar was the seemingly sloppy woodworking inside the guitar. You can see the rough "file-like" grooves in the bracing. I'm wondering if at some point this guitar went through some extensive repairs and the bracing needed to be replaced. It seems odd to me that something like this would come out of the New Hartford factory.

Here's another apparent woodwork flaw. It looks like the epaulet holes were cut right into the edges of the bracing, strange...

Notice the messy wiring hole cut into the left side of the bridge slot. It looks like it was manually performed. The soundboard's black paint is showing in portions of the bridge saddle slot. No doubt an attempt to lower the action of the guitar as the top pulled further and further away from the bowl. An attempt to route the bottom of the bridge saddle slot probably failed leaving an uneven surface. I'm debating whether or not to install a new bridge (if they are even available) or not. I can't even imagine how I would go about clamping something like this!

A small piece of the epaulet cracked off, and was poorly glued back into place. It looks like I'll be able to remove, clean and re-install this piece. That should be relatively easy. Whew...

The inside of the guitar looks to be in good order, but I noticed that the spruce seems to be covered with some other layer near the epaulets? Notice the change in wood grain...or is that a change in sanding stroke...or something? What is that?

Here's another shot of the gapping mouth. Keep in mind that the strings are removed! I'm going to need to think through each of these repairs carefully before I get started, and just progress slowly. Is this 1868 beyond hope, or is there still a chance that I might here her sing again? Any advice and/or suggestions from the OFC would be most appreciated and welcome. Thanks!

Edited by arumako 2014-11-16 12:30 PM

| |

| | |

Joined:

June 2012

Posts: 112

Location: Bristol England | Hi Ho Dan Savage. Cue William Tell overture. | |

| | |

Joined:

March 2005

Posts: 2791

Location: Atlanta, GA. | If you can't repair it, any chance of recovering you investment by parting it out?

Neck, tuners, OP pre amp, case, etc. | |

| | |

Joined:

October 2012

Posts: 1093

Location: Yokohama, Japan | cholloway - 2014-11-16 4:31 AM

If you can't repair it, any chance of recovering you investment by parting it out?

Neck, tuners, OP pre amp, case, etc.

Yes, I can. tpa suggested the same on my post in the "General" forum. All the separate parts would more than recover my investment. That really gives me some assurance, and frees my mind up to dive into this project...but oh, so slowly...

And after taking measurements, it's very clear that the bowl was filed down at the butt end of the guitar. That's why it takes a lot of pressure to push the top down to contact the bowl. At it's lowest point, the ring of the bowl that adheres to the sound board has been shaved down by 1 full millimeter. If I can't raise that area back-up to the proper specs, the top will not be flat!

Does anybody know of some good plastic material that will adhere strongly to lyrachord? It looks like I'll need to make a shim to fit between the bowl and the top...

jamesholl's got it right. DanSavage! HELP...

Oh, yeah...I remember DanSavage talking about the different lyrachord bowls...I'd better go back and look at the "1619-4 Rebuild" thread for a refresher course on "O" bowls...here goes nothing!

Edited by arumako 2014-11-17 6:05 AM

| |

| | |

Joined:

December 2003

Posts: 13996

Location: Upper Left USA | If it were on my project shelf...

I would plan a re-topping project. | |

| | |

Joined:

August 2007

Posts: 1008

Location: Tuscany, Italy | I just recognized that pics of your 1868 are here. Forget my request on the other post.....  | |

| | |

Joined:

June 2012

Posts: 2344

Location: Pueblo West, CO | arumako - 2014-11-17 3:57 AM

Does anybody know of some good plastic material that will adhere strongly to lyrachord? It looks like I'll need to make a shim to fit between the bowl and the top...

jamesholl's got it right. DanSavage! HELP...

Oh, yeah...I remember DanSavage talking about the different lyrachord bowls...I'd better go back and look at the "1619-4 Rebuild" thread for a refresher course on "O" bowls...here goes nothing!

Quite an undertaking, Arumako.

Personally, I would not use a 'plastic' as a shim. I would use G10, which is an industrial-grade fiberglass sheet. It comes in different thicknesses. The thinnest G10 I've seen is .08mm. (1/32")

For gluing the G10 to the bowl and top, I would use Loctite Hysol 9462. It's an aerospace-grade epoxy. It glues wood, plastic, fiberglass (epoxy & polyester), metal, etc. It's temperature range is -65° to 250° F and is impact-resistant. It's the strongest glue I've ever used and forms a nearly unbreakable bond.

Remember that Lyrachord is simply the trade name used by Ovation for the fiberglass bowls. The hand-laid bowls are epoxy-based and use woven cloth. The SMC bowls are polyester-based and use fiberglass roving.

To bond either one, you'll need to make a purely mechanical bond since the resin has already fully cured. Chemical bonds with resin can only be made if it is not fully cured. (polymers not fully cross-linked) Once the polymers are cross-linked, then you can only scuff the surface to give the new glue some tooth.

Dan

Edited by DanSavage 2014-11-17 1:21 PM

| |

| | |

Joined:

June 2012

Posts: 2344

Location: Pueblo West, CO | MWoody - 2014-11-17 5:46 AM

If it were on my project shelf...

I would plan a re-topping project.

Yep. If the top requires a lot of pressure to keep it in contact with the kerfing, that might be the best solution in the long run. | |

| | |

Joined:

October 2012

Posts: 1093

Location: Yokohama, Japan | DanSavage - 2014-11-17 3:13 AM

Quite an undertaking, Arumako.

Personally, I would not use a 'plastic' as a shim. I would use G10, which is an industrial-grade fiberglass sheet. It comes in different thicknesses. The thinnest G10 I've seen is .08mm. (1/32")

For gluing the G10 to the bowl and top, I would use Loctite Hysol 9462. It's an aerospace-grade epoxy. It glues wood, plastic, fiberglass (epoxy & polyester), metal, etc. It's temperature range is -65° to 250° F and is impact-resistant. It's the strongest glue I've ever used and forms a nearly unbreakable bond.

Remember that Lyrachord is simply the trade name used by Ovation for the fiberglass bowls. The hand-laid bowls are epoxy-based and use woven cloth. The SMC bowls are polyester-based and use fiberglass roving.

To bond either one, you'll need to make a purely mechanical bond since the resin has already fully cured. Chemical bonds with resin can only be made if it is not fully cured. (polymers not fully cross-linked) Once the polymers are cross-linked, then you can only scuff the surface to give the new glue some tooth.

Dan

Thanks for commenting DanSavage. The wealth of knowledge and experience you bring to every BFLG discussion are just priceless. Reading your comments and analysis always brings perspective and direction that would otherwise be unattainable...which puts you up there in the clouds beyond "Master Luthier" and into the realm of "Luthier-Guru!"

So, I'll need to take a look to see if any of these materials are available here in Japan. If not, I'll need to have them sent from the States. I am considering the top change that MWoody also suggested, but it looks like I'll first need to restore the SSBs dimensions and verify structural integrity before I worry about the top. I've got a really nice Sakura (Japanese Cherry) wood blank that I'm planning on using when I change the top on my CC54i next summer, but I think spruce or cedar would be more appropriate for this 1868. The only thing that really worries me about changing the top on an Elite (a scenario I'll eventually have to face when I work on my CC54i) is clamping. I'd need to make some jig that will enable me to clamp the top to the bowl, bridge to the top, and neck to the body assembly. When the back is round, it all seems pretty intimidating because there is no "C-clamp friendly" centrally located sound hole!

Right about now, I'm feeling like Pooh-bear, "think, think, think..."

Edited by arumako 2014-11-17 9:22 PM

| |

| | |

Joined:

November 2002

Posts: 3658

Location: Pacific Northwest Inland Empire | Three words.......surgical rubber tubing. Takes care of the "C-clamp-friendly" issue. Makes everything line up, too. Whether it wants to, or not. | |

| | |

Joined:

October 2012

Posts: 1093

Location: Yokohama, Japan | seesquare - 2014-11-17 1:30 PM

Three words.......surgical rubber tubing. Takes care of the "C-clamp-friendly" issue. Makes everything line up, too. Whether it wants to, or not.

Ah ha, thanks seesquare! I've seen pictures with guitar tops wrapped up in some rubbery looking mess! I never would have guessed - surgical rubber tubing! Very cool! Now this is starting to get interesting. I found out that the Mini-Mother has a new 1868 bridge that I can buy...must be some kind of divine direction or something...

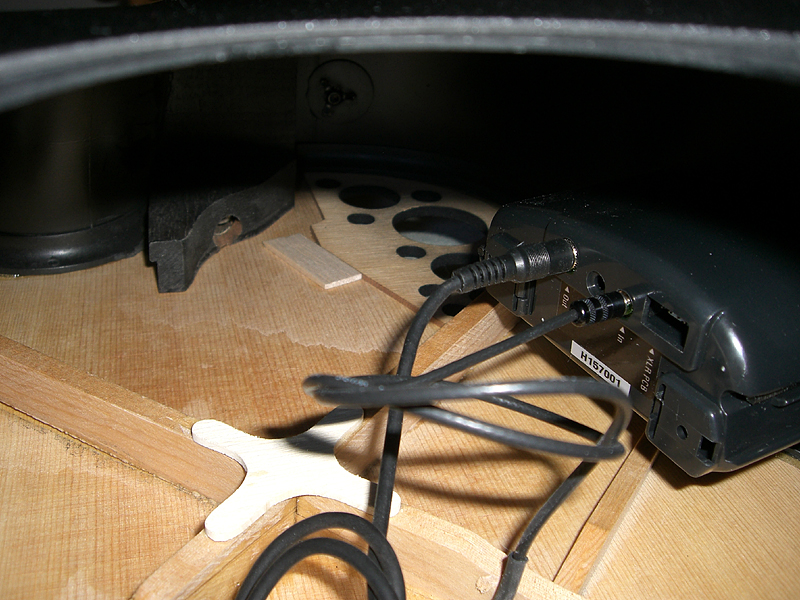

For now, I wrapped my Elite in (not the surgical tubing, but the more common) rubber band, ha! Had a bunch in different sizes just laying around. I know it's a long shot, but I was hoping the banding force my encourage the top to straighten out just a little. In this condition, the neck angle seems to be perfect, but I'll still probably need to perform a very minor neck reset, because the bridge saddle slot was routed too deeply (thank God for bolt on necks).

I think I'll leave her this way until the G10 material arrives. Loctite Hysol 9462 is sold in Japan, but because of its "industrial" designation, they will sell it to businesses and licensed individuals only! I'll need to order it from the States! Anyway, thanks for all the valuable BFLG input! I really appreciate it! Now to source, order and wait for the materials to arrive...patience is a good thing... The rubber bands kind of give my Elite an Eddie Van Halen-ish flair!

Edited by arumako 2014-11-18 9:40 AM

| |

| | |

Joined:

October 2005

Posts: 4079

Location: Utah | A couple of thoughts.

Your current top needs to be significantly changed due to warping and the bowl being trimmed. Wetting the wood might be worth trying, and if it ends up worse, it doesn't matter because it is not usable the way it is now.

Could you cut down the rest of the bowl to match the part which was trimmed? So rather than trying to get some material to stick to the damaged part of the bowl you could instead trim the rest of it down. You'd then have a SSSB.

You may be able to make (or buy from the service department) a suspension ring? The ring does raise the top a small amount compared to the same bowl without the ring. It may be easier to glue the top down to the suspension ring than to the damaged bowl or even to a repaired bowl.

When it comes to gluing the bridge on a new top, you could dry fit the top but don't glue it down yet to the bowl. If the top fits snugly into the bowl it won't move, and you can accurately place the bridge. Once you get it measured and mark the top, remove the top and glue the bridge on. Then you can glue the top to the bowl.

It looks like a big job ahead for you on this one. Good luck! | |

| | |

Joined:

June 2012

Posts: 2344

Location: Pueblo West, CO | Rubber bands work good, too.

You can get G-10 and 9462 online from McMaster-Carr. (mcmaster.com) I'm not sure if they ship to Japan, but it's worth checking.

Loctite adhesives: http://www.mcmaster.com/#high-strength-adhesives/=unexl8

For some jobs, the dispenser gun and mixing nozzles work really well and are worth the money.

G-10: http://www.mcmaster.com/#grade-g-10-phenolic/=uney8h

| |

| | |

Joined:

December 2004

Posts: 578

Location: Denmark | Since the neck seems bolt-on it could make sense trying to disassemble neck/top/bowl. | |

| | |

Joined:

December 2004

Posts: 578

Location: Denmark | Regarding the saddle slot in the bridge being too deep you could also just glue in a piece of wood of suitable quality and thickness to form a new bottom on correct depth. Then you will not risk the top finish in trying to remove the old bridge.

If you find a glue/surface preparation that will stick to the inner side of the bowl you can make a new surface to glue the top to by making a kerfing based on a profile that matches the shallow cowl and the top. This will be easier if the top can be removed, but this removel has other challenges.

http://jcclarkukuleles.wordpress.com/my-guitarmaker-articles/making...

Edited by tpa 2014-11-18 2:07 PM

| |

| | |

Joined:

November 2002

Posts: 3658

Location: Pacific Northwest Inland Empire | That's an excellent suggestion, tpa! Glue in the kerfing strips, to the original bowl/top specs, and glue a new top to the "raised" kerfing, then route a-bit-wider binding channel, glue on the new binding, & "nobody's-the-wiser"!

As they say, "Run it up the flagpole, & see who salutes"

Best of luck there, arumako. Our collective opinion, & a dollar, may get you some cheap glue!! | |

| | |

Joined:

October 2012

Posts: 1093

Location: Yokohama, Japan | seesquare - 2014-11-18 4:34 AM

...Best of luck there, arumako. Our collective opinion, & a dollar, may get you some cheap glue!!

Thanks seesquare, and everybody else for the valuable input! It's all going to get me more than cheap glue! It's going to get me a restored 1868 Elite! I really like the wood kerfing idea! That should be pretty easy to make. The only issue (for me, anyway) will be to make sure the kerfing adhere's to the bowl and top adequately. I'll definitely need to get the hysol 9462 (thanks for the link DanSavage). But I also like the idea of the suspension ring. I think I'm going to see if the Mini-Mother has one available that they can send along with the bridge.

One of the advantages of the neglect that this guitar has gone through is that the original epoxy has become quite brittle. With a sharp chisel, the epoxy is just flaking off. That probably means that the guitar is really in need of a sound board upgrade with fresh adhesives, and the sound board should be pretty easy to take off. Removing the neck and top make it easier to repair the bowl; and if I get a suspension ring, I'll need to take the top off anyway.

Taking the top off will also give me the opportunity to see if the top will flatten out. I can sandwich the top between some flat aluminum sheets - applying steady heat and some humidity should flatten out the top real nicely. If not, bear claw spruce? This is getting interesting...thanks again for all the valuable advice!

Edited by arumako 2014-11-19 10:29 AM

| |

| | |

Joined:

August 2007

Posts: 1008

Location: Tuscany, Italy | Dan, is this the adhesive you are talking about ...?

http://www.ebay.it/itm/Loctite-Hysol-9462-Aeropoxy-/321436112051?pt... | |

| | |

Joined:

June 2012

Posts: 2344

Location: Pueblo West, CO | maremagnum - 2014-11-19 9:51 AM

Dan, is this the adhesive you are talking about ...?

http://www.ebay.it/itm/Loctite-Hysol-9462-Aeropoxy-/321436112051?pt=UK_ToysGames_RadioControlled_JN&hash=item4ad715d4b3

Yep. That's the one.

I forgot that to use it you do need to dispenser gun, or at least a 1.69ml 1:1 plunger to squeeze the glue out of the tubes.

See:

http://www.mcmaster.com/#high-strength-adhesives/=unyuof

http://www.mcmaster.com/#74695a71/=unyuazThe mixer nozzles aren't necessary unless you're intending to lay out a long bead of adhesive. If you do decide to get some mixer nozzles, make sure they're the long nozzles as the short nozzles don't adequately mix the two parts of the epoxy.

Edited by DanSavage 2014-11-19 1:22 PM

| |

| | |

Joined:

October 2012

Posts: 1093

Location: Yokohama, Japan | I had a day off today, and made some progress on disassembling my 1868 Elite... found some interesting things as I progressed.

I love these bolt on necks. This one came off clean and easy, BUT...notice the masking tape, strange. The top has markings on it that said 1868-5. The soundboard was much thicker than I expected, about 3mm! I also noticed that there is another layer of wood under the spruce. Are all Elite's made that way?

Lots of glue under the neck, and on the body where the fingerboard meets the soundboard, but I should be able to clean this up and get it to adhere to the top when I reassemble her.

Whoever worked on this guitar messed up the bridge pretty badly...routed right through the bridge and...

Lots of epoxy to fill in the over routed bridge saddle slot. The router went through the black paint and into the spruce top in some spots...cringe factor! But, JB at the Mini Mother sent me a new walnut bridge saddle (he is just the nicest guy), so if I fill in the over routed area with epoxy or CA glue, I should be able to just glue the new bridge into place with out much fuss!

The top came off really clean too! The epoxy has become very brittle over the years making removal a slow, but simple task. I might even be able to re-use it...only...

Now that the top is completely off of the bowl, the whole thing is concave! Weird! I was also wondering about an extra layer of wood that is apparently under the epaulets as shown in the next picture.

Are the Elite soundboards laminated under the epaulet area? The wood was very soft and I had to work really slowly to get this part off clean. You can tell by the change in the wood grain and color. Is this standard Elite design?

Finally, the bowl...the bowl is in good shape, but looking at the epoxy residue on the bowl. It is pretty clear to me that the top and bowl had flatness and fitting problems. I don't know if it was a factory issue or a failed restoration, or what, but when I measured the epoxy thickness between the bowl and the soundboard, there were variation in epoxy thickness. In some places the epoxy was 2mm thick, in other places it was too thin to measure. I know Ovations were notorious for the amount of epoxy used to adhere the bowl to the soundboard, but was this kind of variance seen in a lot of Ovation assemblies? In any case, I'm really glad I was able to make some progress on this project. As usual, I sure would appreciate your comments and analysis. Oh yeah, as I was heating the bridge, the finish on my Elite bubbled up in a really small area around the bridge. It looks like if I heat the whole top, the paint will just peel right off, so if removing the paint will help the top flatten out, I might re-use the top and re-finish the whole thing! This is getting exciting!

Edited by arumako 2014-11-24 9:00 AM

| |

| | |

Joined:

October 2005

Posts: 4079

Location: Utah | Looking good so far! I am impressed you were able to disassemble it without damage. | |

| | |

Joined:

March 2005

Posts: 12761

Location: Boise, Idaho | Nice work! Regarding the extra piece of wood under the epaulets, I only know that the earliest Elites, the 1537s, had that extra piece of wood there. I don't know how long they continued doing that. | |

| | |

Joined:

December 2004

Posts: 578

Location: Denmark | arumako - 2014-11-24 8:51 AM

Lots of glue under the neck, and on the body where the fingerboard meets the soundboard, but I should be able to clean this up and get it to adhere to the top when I reassemble her ... The top came off really clean too! The epoxy has become very brittle over the years making removal a slow, but simple task....

Somewhere I read that on the (older?) Adamas guitars this overlapping fretbord end was not fixed to the soundbord, but on cut-away guitars this part of the soundboard is probably relatively dead soundwise anyway. Regarding the brittleness - I suppose that there diferences in the long-term degradation of properties depending on type and brand. I am no specialist but I have the impression that short term properties are normally considered better for the slow and/or elevated temperature curing types.

I follow the work of You and DanSavage with admiration, pleasure and interest. Thank you for sharing.

http://en.wikipedia.org/wiki/Phoenix_%28mythology%29

Edited by tpa 2014-11-24 11:18 AM

| |

| | |

Joined:

March 2005

Posts: 12761

Location: Boise, Idaho | tpa is right, but the "floating fretboard" was also used on the first of the Elites. I don't know how long they continued to do that, either. When I saw the pictures with all the glue under the end of the fretboard, I thought someone might have tried to glue it down, thinking that it had pulled up. We've seen several examples of people trying to fix that on old Elites when it wasn't really broken. On the old ones, there should be a slight gap, probably credit card thickness. | |

| | |

Joined:

September 2006

Posts: 10777

Location: Keepin' It Weird in Portland, OR | "Are the Elite soundboards laminated under the epaulet area?"

My 1735 is like that also...

| |

| | |

Joined:

June 2012

Posts: 2344

Location: Pueblo West, CO | The doubler(s) on my 2078TX-5 is only under the immediate area around the epaulet holes. This may be because the neck is glued on and doesn't need to be self-supporting like the bolt-on neck models.

Edited by DanSavage 2014-11-24 1:37 PM

| |

| | |

Joined:

June 2012

Posts: 2344

Location: Pueblo West, CO | arumako - 2014-11-24 6:51 AM I had a day off today, and made some progress on disassembling my 1868 Elite... found some interesting things as I progressed. Whoa! You don't waste much time, do you? (heh heh heh...)

The masking tape was probably a shim to make the neck fit right.

The routed bridge saddle slot was probably an attempt to lower the saddle height in response to the change in neck geometry that was raising the height of the action. This solution is not uncommon.

Personally, I would not attempt to re-use the old top. Besides being old and warped, it will be difficult to get it aligned which will make it harder to put in new purfling and binding.

I would guess that the excess epoxy on the kerfing was a result of a botched restoration rather than something done at the factory. The amount of epoxy between the top wood and kerfing has been pretty consistent on all three of the guitars I've got in my shop.

The US factory wasn't shy about using a lot of glue, which translated into excessive amounts of squeeze-out. But the actual glue joint thickness has been fairly consistent.

In contrast, the Chinese always seem to pay bonuses to their workers based on how little glue they use. The inside of my 2078TX-5 has little to no squeeze-out along the edge of the kerfing and binding. When I was building/flying model airplanes, this as a running joke. One of the things that always needed attention first was to reinforce the glue joints. Otherwise the model could and often did, disassemble itself in the air.

Like I say, personally, I would just plan to re-top the guitar using fresh wood and save the old top for reference for bracing & epaulet hole size/location.

Edited by DanSavage 2014-11-24 1:56 PM

| |

| | |

Joined:

August 2007

Posts: 1008

Location: Tuscany, Italy | I think all guitars with epaulettes have the area around the sound port reinforced. My elite (single epaulet) has the reinforcement.....just saying... | |

| | |

Joined:

October 2012

Posts: 1093

Location: Yokohama, Japan | tpa - 2014-11-24 1:17 AM

Somewhere I read that on the (older?) Adamas guitars this overlapping fretbord end was not fixed to the soundbord, but on cut-away guitars this part of the soundboard is probably relatively dead soundwise anyway. Regarding the brittleness - I suppose that there diferences in the long-term degradation of properties depending on type and brand. I am no specialist but I have the impression that short term properties are normally considered better for the slow and/or elevated temperature curing types.

I follow the work of You and DanSavage with admiration, pleasure and interest. Thank you for sharing.

Thanks for the kind comment tpa, I really appreciate all the input and encouragement. After reading your post and Mark in Boise's post...

Mark in Boise - 2014-11-24 2:52 AM

tpa is right, but the "floating fretboard" was also used on the first of the Elites. I don't know how long they continued to do that, either. When I saw the pictures with all the glue under the end of the fretboard, I thought someone might have tried to glue it down, thinking that it had pulled up. We've seen several examples of people trying to fix that on old Elites when it wasn't really broken. On the old ones, there should be a slight gap, probably credit card thickness.

...I'm beginning to think that this might have been a floating fret board Elite. It's a 1990 model. I wonder if they made the 1868s that way back in those days? Looking at the glue under the neck and on the body, it certainly looks like the glue was added later. I need to try to learn more about the original condition of this guitar. If it was a floating fret board, then I would sure like to restore it to that condition, as those are probably few and far between now...

On closer inspection, I can see that this was a botched up re-gluing of a soundboard that was peeling away from the body. Some of the braces were also re-glued or replaced; hence the messy wood work in several areas. Who ever replaced and re-glued the braces used a glue that dries white...as in Elmers? Holy molly I hope I am wrong about that assessment! I placed the bowl on a perfectly flat surface and the flatness of the top of the bowl is way-off. It's been filed down by the butt end and the two sides of the bowl. So I can either take everything down a bit or build the butt end and sides up a bit. JB at the Mini-Mother seems to think that rebuilding the filed down areas of the bowl with epoxy (may not be the best solution, but) should be structurally sound.

And thanks for all the comments regarding the reinforcement under the epaulets. Especially OMA and DanSavage for looking under the hood of their 1735 and 2078TX-5 respectively. I took a look at my iDea and it also has a reinforcement that is only applied directly under the 3 oval sound holes. OMAs 1735 looks closest to my 1868 and as marenostrum says, apparently all Elite style guitars have reinforcements under the epaulets...very interesting. The reinforcement on my 1868 is super soft. If I didn't know any better, I'd say it was some kind of balsa wood...I'm sure my assessment there is definitely off, but I had to go really really slow removing that section from the bowl because the wood was so soft...

So at this point, I'm thinking I want to keep the guitar in as original condition as possible. I'm planning on rebuilding the sides of the bowl with G10 and Hysol 9462. Get a nice flat surface on the bowl. For the top, I'm going to heat the polyurethane finish, scrape it off nicely and see if it returns the top to a flat state. If it does, I think I'm going to re-use the top and return it to as original a condition as possible. If not, I'll have to take the re-top route which will obviously be the best way to completely revive this beauty.

By the way, if this is a floating fret board Elite, I'm assuming I need to bolt and glue the heel of the neck to the bowl. There's a very thin residue of glue on the heel of the neck where the Kaman bar meets the body. The adhesive would have to work on aluminum, wood and fiberglass. Does anybody know what kind of glue is used for that? Perhaps CA glue?

I sure do appreciate your input OFC! Domo Arigato Gozaimasu! | |

| | |

Joined:

December 2003

Posts: 1889

Location: Central Massachusetts | DanSavage - 2014-11-24 2:35 PM

The doubler(s) on my 2078TX-5 is only under the immediate area around the epaulet holes. This may be because the neck is glued on and doesn't need to be self-supporting like the bolt-on neck models.

Dan, is that a loose brace there on the left of this pic? | |

| | |

Joined:

June 2012

Posts: 2344

Location: Pueblo West, CO | dvd - 2014-11-25 6:54 AM

Dan, is that a loose brace there on the left of this pic?

Good eye. It was loose at the time I took the pic. Afterward I went in and glued it down. That was my first ever Ovation repair.

The back story is that I bought the husk off ebay. It was a factory reject that didn't have any hardware. So, I bought the hardware and put it together. I liked the sound, but the low E and A had a dead tone. I took the pics of the inside because there was some discussion about the imported guitars having top wood that was twice as thick as the US of the same model. After taking the pics I saw that the brace looked loose, so I went back in and sure enough, it had popped loose. So, I used some medium CA to glue the brace back down and the dead tone of the E and A strings went away. I also cleaned up some of the squeeze-out on the other braces and it improved the overall tone of the guitar.

The guitar still sounded stiff, so I bought a PrimeVibe and used it on this guitar and it really loosened up the top and improved the sustain and depth of the sound, especially the bass. | |

| | |

Joined:

June 2012

Posts: 2344

Location: Pueblo West, CO | Hi Arumako,

I don't think yours has a floating fretboard. Someone (OMA?) posted pics of one of his Elites with a floating fretboard a while ago after he'd taken off the neck and there's a pocket in the top and the fretboard extension sits on an extended support block that extends almost to the end of the fretboard extension. I don't see either one on your guitar. There's an article in Guitar Player magazine from 2005 that talks about it and the other new features of the LX series guitars. (See: Ovation LX Series) Edit: I found a thread here on OFC that shows the floating fretboard. See: Tension Rod question

Elmer's glue dries clear or slightly translucent, so if the glue you're seeing on the braces is white, it's probably some sort of epoxy, like Hysol or possibly, polyurethane glue like Gorilla Glue.

I agree. I would use G-10 and Hysol to build up the sides of the bowl rather than try to take the high spots down. These two materials will give you something that's as strong and stable as the original material used. I think trying to take the sides down will be pretty difficult and will cause other problems, such as too big of a gap where the fretboard joins the top. Also, lowering the top will, in effect, raise the neck, which will also raise the action.

In looking at the pics of the cross-grain reinforcement, I don't think it's balsa. Balsa, like spruce, has a tight grain structure. The cross-grain wood looks to me like either basswood or maybe soft pine. One way to check if it's balsa is to try to make a splinter of a piece of it and see if it wants to pierce your skin. (gently, please... LOL!) Balsa is used in the entertainment industry for visual effects exposions because it won't splinter and break the skin like pine, etc.

You don't want to glue the heel to the body. Bolting it is plenty strong. If someone tried to glue the heel to the body, then they didn't know what they were doing. Hysol 9462 will bond all of those materials, but like I say, you don't want to glue the heel. The only part that should be glued is the fretboard extension to the top and even then, you only want to apply a thin bead around the edge to keep it stable. If you leave it unglued, the strings will have a dead sound when you fret them above the 14th fret.

Dan

Edited by DanSavage 2014-11-25 12:25 PM

| |

| | |

Joined:

May 2008

Posts: 1565

Location: Indiana | Enjoying watching your progress, arumako.

Regarding the bridge routing, I have two guitars that came from the mothership routed through to the top. One from the 80's, one from the early 90's.

Keep up the good work! | |

| | |

Joined:

October 2012

Posts: 1093

Location: Yokohama, Japan | Jonmark Stone - 2014-11-25 2:40 AM

Enjoying watching your progress, arumako.

Regarding the bridge routing, I have two guitars that came from the mothership routed through to the top. One from the 80's, one from the early 90's.

Keep up the good work!

Thanks for the kind comments Jonmark Stone. I'm surprised to hear that the Mothership actually routes into the top! But I guess in so many vintage O restorations, the only other option is a "bowl bend" like DanSavage is doing with the "1967 Balladeer Rebuild". That seems pretty risky! I am learning a ton about guitar rebuilds from the OFC, and I am just glad to share my journey! Please pray that I won't end up tanking this beauty in the trash. The more hours I put into it, the more I want to save her!

DanSavage - 2014-11-25 2:20 AM

Hi Arumako,

I don't think yours has a floating fretboard...

...In looking at the pics of the cross-grain reinforcement, I don't think it's balsa... Balsa, like spruce, has a tight grain structure. The cross-grain wood looks to me like either basswood or maybe soft pine. One way to check if it's balsa is to try to make a splinter of a piece of it and see if it wants to pierce your skin. (gently, please... LOL!)...

...You don't want to glue the heel to the body. Bolting it is plenty strong. If someone tried to glue the heel to the body, then they didn't know what they were doing...

Dan

Thanks for the heads up and links to the thread with the floating fretboard pics! You saved me from making a huge mistake! Like an idiot, I would have glued the heel to the bowl with a credit card thick gap between the fretboard and soundboard, and wondered why my fretboard keeps bending and hitting the soundboard everytime I play on the higher frets! Doh!

Balsa or pine? Ouch! PINE...pass the bandaid please...(so thankful that this 1868's well-being is NOT dependent on my observation skills!)

Yup, someone tried to glue the heel! And the comment thereafter, kind of "sums up" the jist of the condition of this guitar!

However, I am not going to give up yet! If you are not used to seeing guitar carnage, the next few pictures may not be for you. Don't say that I didn't warn ya!

So, I wanted to see how far I could go to salvage this top. She was bone dry and curling up at the sides, and I wanted to learn what it would take to re-finish an O...you know, just in case... so I took out my iron and heated up the polyurethane finish, and boy did she peel off easily!

It actually took a pretty long time to do, but the work was actually pretty easy...just needed patience. And the next pic might just make you want to kill me!

I know, I know, "O-Abuser"...please forgive me! So since she was bone dry and curling up at the sides, I decided to put her in an 80% humidity room. She's been there for 12 hours and...

She's flattening out! Whoa Cool! But alas, I've decided to take everybody's advice and go with a top change. One more dry spell and this top is going to crack like so many acoustic tops do... My daughter made me promise to re-store this to the original black condition. She really likes the 1868 "-5" finish, and seems to be intent on using this guitar when I'm done so... The original 1868-5 specs say the soundboard is made from AA Spruce. So, I checked out Stewmac's website and dreadnought size AA Spruce is going for a mind-boggling 20 bucks! No wonder why you all were saying, "Swap the top!" I must say, I am learning so much from this project, and I am just addicted to guitar restoration! I thought GAS was the abyss, but the BFLG is the abyss within the abyss!

Edited by arumako 2014-11-26 4:47 AM

| |

| | |

Joined:

October 2005

Posts: 4079

Location: Utah | Do you have a source of tone wood nearby? I've seen videos of people tap testing wood to find the piece with the nicest sound when tapped. Some pieces sound dull, others have a clear resonance. StewMac is a good source, I'm just wondering if you can do better. | |

| | |

Joined:

June 2012

Posts: 2344

Location: Pueblo West, CO | Howdy!

That's one of the great things about working on guitars, with a few exceptions, nothing is permanent. Most mistakes can be fixed, albeit with a certain amount of effort.

When I was gathering materials for my 1619, I bought Stewmac's cheap sound board to practice on. It's actually pretty nice wood, with good tap tones.

What I've learned about grading is that it has more to do with appearance than with acoustic qualities. The higher grades have grain that is tighter, straighter and is evenly spaced across the entire piece.

If you're going to paint your black, then you may as well get the cheap wood. In fact, if you're going to buy the cheap wood, order two sets while you're at it. This will give you something to practice on.

Here's a good site that shows step-by-step guitar building. While a lot of it is about building a wood box, the parts about joining the top wood, making and gluing the braces are applicable to the job at hand. (See: Hoffman Guitar Building) Keep up the good work! Dan | |

| | |

Joined:

October 2012

Posts: 1093

Location: Yokohama, Japan | DanSavage - 2014-11-26 2:01 AM Howdy!

That's one of the great things about working on guitars, with a few exceptions, nothing is permanent. Most mistakes can be fixed, albeit with a certain amount of effort.

When I was gathering materials for my 1619, I bought Stewmac's cheap sound board to practice on. It's actually pretty nice wood, with good tap tones.

What I've learned about grading is that it has more to do with appearance than with acoustic qualities. The higher grades have grain that is tighter, straighter and is evenly spaced across the entire piece.

If you're going to paint your black, then you may as well get the cheap wood. In fact, if you're going to buy the cheap wood, order two sets while you're at it. This will give you something to practice on.

Here's a good site that shows step-by-step guitar building. While a lot of it is about building a wood box, the parts about joining the top wood, making and gluing the braces are applicable to the job at hand. (See: Hoffman Guitar Building) Keep up the good work! Dan Thanks a bunch DanSavage. I will definitely get two sets of the AA Spruce StewMac soundboards to practice on. Actually, I was thinking of trying out the bearclaw spruce that you used on the 1619, or redwood (like Patch's or DVD's) beauties. The exotic woods are very tempting, but my daughter was unusually insistent; and this being my first complete guitar top build, I figured, I'd better take the conservative approach, and try more exotic stuff as I build experience! @FlySig, yup, two tone wood suppliers around here. Gave them a call and found out they get their stuff from, guess who...? StewMac, and their imported AA spruce tops are 4 times the price! Ouch! I haven't read any bad reviews on those AA spruce tops; so I think, I'm going to go ahead and take the plunge. Now, to order all the parts and wait...I'm hoping to finish the project before the year is out... Anyway, thanks for all the valuable advice! I pray a very happy Thanksgiving for all of the BFLG and OFC folks out there! | |

| | |

Joined:

June 2012

Posts: 2344

Location: Pueblo West, CO | You're welcome.

The bearclaw (BCS) did sound different from the AA during tap tests. The BCS had a slightly sharper tone and was slightly less resonant. The AA was slightly lower in pitch and had just a little more resonance. IMO, either one would make a nice-sounding guitar.

I've never heard what a redwood guitar sounds like, so I'll let Patch chime in. (pun, intended)

In all fairness to your local suppliers, they need to make a profit, so it makes sense that they would roll the shipping costs and a mark-up into their wood prices. I'm not sure I'd be willing to pay $80/set unless I was unable to get it anywhere else.

Thanks and you're very welcome. I enjoy watching and reading about your progress. Happy Un-Thanksgiving to you, too.  | |

| | |

Joined:

October 2012

Posts: 1093

Location: Yokohama, Japan | Getting all excited after seeing DanSavages 1967 Balladeer Rebuild, just awesome... but it has become apparent, that I won't be able to get Hysol 9462 here in Japan (although it is available, licensing is required as it is categorized as an industrial grade adhesive). Bummer... Instead of using some less effective substitute I thought I'd better wait for opportunity to strike, and it looks like I'll be in the States for a week at the end of the August! So, I can buy it and ship it to myself. Cool!

On another note regarding the bowl repair, a friend of mine who builds surf boards suggested that I repair the bowl using resin and fiberglass sheets. It sounds possible if I building a dam around the kerfing to make sure the resin stayed where it needs too. Cut the fiberglass sheets into thin slices and build up the entire kerfing area and sand down to flatness... It sounds like it would be trickier than fixing the back of the bowl like in DanSavage's 1619-4 Rebuild, but I wonder if the fiberglass/resin will adhere to the bowl. Since it is the kerfing, the newly applied fiberglass resin layer will need to withstand quite a bit of force. Using G10 will no doubt be easier, but... hmmm, decisions, decisions... | |

| | |

Joined:

October 2012

Posts: 1093

Location: Yokohama, Japan | FlySig - 2014-11-18 12:30 AM

Your current top needs to be significantly changed due to warping and the bowl being trimmed. Wetting the wood might be worth trying, and if it ends up worse, it doesn't matter because it is not usable the way it is now.

This 1868 project has been sitting on the shelf for quite a while. Just waiting for some open time to dig into it, but the other day, as I walked by the sound board that was leaning against the wall in front of my work desk, I spilled a cup of water that splashed all over the soundboard! I wiped off the sound board, and left it where it was; then to my great surprise, the next day, the board was slightly flatter than it was the day before. So I went back and read through this post again, and saw FlySig's comment about "wetting" the wood.

I also did some research on how wood workers flatten veneers, and I decided to give this warped sound board one more try! A slightly wet rag was used to wipe on the moisture, and after a few minutes I could tell the surface was softening up a bit...Cool!

I also wet the back a bit and put the sound board between some weights...

I learned that the paper towel and air pockets above and below the weighed down sound board was essential to ensure the wood dried out sufficiently. Since this top is now 26 years-old, I suspect it might be a little like DanSavage's torrefied tops. The thing is the top came out completely flat! So, since I had nothing to lose, I sanded the black residue from the top of the sound board as best I can, and used some Japanese Calligraphy ink called "sumi" (which is filled with minerals) to see if I can get a bit of a black wash effect on the sound board...

If I darken the edges with a solid black color , add the standard epis and clear coat it with polyurethane, this might turn out kinda nice! The neat thing is, now that the top is flat, it seems to fit the bowl much better than before! My daughter originally wanted this guitar when it was fixed, and asked that it stay black, but the long wait seems to have waned her interest; so I kinda have my sights set on a blackwash finish. Anyway, a little mishap has steered this 1868 Project in an interesting direction. Being a 26 year vintage, the sound board has excellent tap tone, and would certainly be worth re-using! Need to experiment more on blank wood to find the right black washing technique. Thanks for the tip FlySig!

Edited by arumako 2016-05-01 8:33 AM

| |

| | |

Joined:

June 2012

Posts: 2344

Location: Pueblo West, CO | arumako - 2016-05-01 6:24 AM

I spilled a cup of water that splashed all over the soundboard! I wiped off the sound board, and left it where it was; then to my great surprise, the next day, the board was slightly flatter than it was the day before. So I went back and read through this post again, and saw FlySig's comment about "wetting" the wood.

I also did some research on how wood workers flatten veneers, and I decided to give this warped sound board one more try! A slightly wet rag was used to wipe on the moisture, and after a few minutes I could tell the surface was softening up a bit...Cool!

The thing is the top came out completely flat! So, since I had nothing to lose, I sanded the black residue from the top of the sound board as best I can, and used some Japanese Calligraphy ink called "sumi" (which is filled with minerals) to see if I can get a bit of a black wash effect on the sound board...

If I darken the edges with a solid black color , add the standard epis and clear coat it with polyurethane, this might turn out kinda nice! The neat thing is, now that the top is flat, it seems to fit the bowl much better than before! My daughter originally wanted this guitar when it was fixed, and asked that it stay black, but the long wait seems to have waned her interest; so I kinda have my sights set on a blackwash finish. Anyway, a little mishap has steered this 1868 Project in an interesting direction. Being a 26 year vintage, the sound board has excellent tap tone, and would certainly be worth re-using! Need to experiment more on blank wood to find the right black washing technique.

It's nice to see this project back on the move again.

WRT to wetting wood, when I was building models and the rounded fuselage needed a fully-sheeting surface, I used to wet the outside of the balsa, which caused it to both soften slightly, and swell on only one side, which warped it in the direction I needed for it to fit on the curved surface. I glued the wood to the framework while it was still wet, then let it dry.

If you want to check what the finish will look like after the clear coat is applied, spray or wipe naptha (white gas - Coleman camp fuel) on the bare wood. It does a good job of simulating the look of the finished wood without any permanent sealing. It evaporates after a few minutes leaving no residue. You could do the same thing with denatured alcohol, but that contains water which might cause the top wood to warp again.

| |

| | |

Joined:

October 2012

Posts: 1093

Location: Yokohama, Japan | DanSavage - 2016-05-01 4:05 AM

It's nice to see this project back on the move again.

WRT to wetting wood, when I was building models and the rounded fuselage needed a fully-sheeting surface, I used to wet the outside of the balsa, which caused it to both soften slightly, and swell on only one side, which warped it in the direction I needed for it to fit on the curved surface. I glued the wood to the framework while it was still wet, then let it dry.

If you want to check what the finish will look like after the clear coat is applied, spray or wipe naptha (white gas - Coleman camp fuel) on the bare wood. It does a good job of simulating the look of the finished wood without any permanent sealing. It evaporates after a few minutes leaving no residue. You could do the same thing with denatured alcohol, but that contains water which might cause the top wood to warp again.

Thanks Dan! Again, being totally inspired by your 1113 Project, and in the process of doing some homework for my CC54i iDea Project (meaning balsa!), I decided to devote a few minutes to my 1868.

It's amazing how much these sound boards respond to humidity. Like Dan said, adding water on the top of the sound board, expands the top and the sound board curls up (convex shape). Adding water to the bottom (between the braces) expands the bottom and the sound board curls downward (concave shape). Very interesting! I wet both and it flattens out completely! But after drying out again, there is still a bit of a curl downward (concave). By the way, I had to be really careful to make sure the epoxy holding the braces didn't get wet (could loosen up the bracing causing it to pop-off later after re-assembly).

But to my great surprise, once the top flattened out, the bowl fit the top nearly perfectly! Raising the kerfing in certain areas of the bowl is still necessary, but no more than 1mm in only 2 places each having approximately a 3cm span! Cool! So, instead of using G10 or the Black Onyx casting resin, I figured just using extra Hysol 9462 in those areas should be sufficient. WOW! What a relief! Really interesting because this suggests that the bowl changes shape depending on how the top is glued on to the bowl (or drastic changes in weather). I remember Dan mentioning that in one of the other threads.

After the top dries; however, there's still a bit of a concave curl, but nothing severe enough to render the sound board useless. But Elite's are really difficult to clamp for me...whether it be the bridge, the neck or the top...so, I've decided to change the order of assembly a bit. First order of business is to get the bridge glued to the sound board...

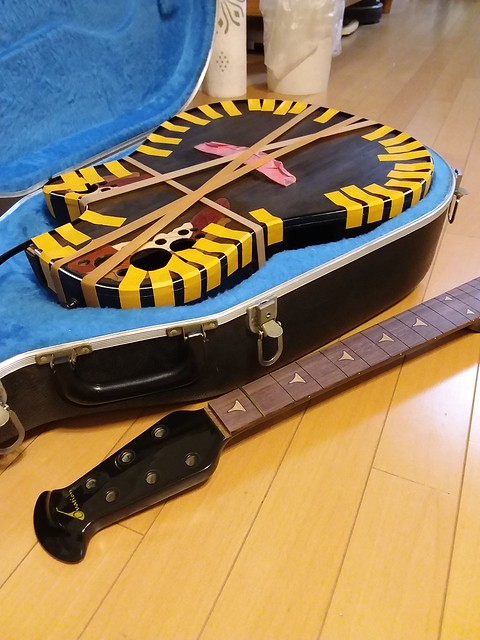

No fancy balsa cauls for this 1868, but some shims and pads do nicely when the top is seperate from the bowl. Waited 48 hours and glued the sound board back to the bowl! YES!

For lack of wisdom intelligence or both, I'm resorting to some strange assembly techniques...a hybrid of rubber bands, clamps, weights and straps... So far, things seem to be lining up really nicely; Since my daughter's lost interest in the color of this guitar (previously demanded the "-5" black finish), I've decided to try some ebonizing using Iron Acetate as a stain (often used when finishing furniture). The batch of iron acetate is about 2-weeks old now, and is a deep red rust color. When applied to the spruce, it should have a deep, deep interesting hue. Wanted the epi's to be under the clear coat; so I'm planning on shallow routes to glue the epi's in place before a final rub on lacquer finish. The routed epi slots need to be completely flat; hence, the sound board was glued to the bowl before installing the epis. A lot of work left, but am very pleased with the progress made in the minimal time spent! Thanks for the inspiration Dan!

Edited by arumako 2016-05-21 12:09 AM

| |

| | |

Joined:

October 2012

Posts: 1093

Location: Yokohama, Japan | And 24 hours later, the Hysol is secure! Now is the time to trim the flashing! After 48 hrs. the glue is very hard and can be difficult to trim...

Everything is lined-up perfectly! Woohoo! Iron Acetate ebonizing in 24 hours! | |

| | |

Joined:

June 2012

Posts: 2344

Location: Pueblo West, CO | Very cool, Ken. Nice job.

I kind of like the rustic look the top has in that last pic. I also think it looks cool with just the holes sans epaulets.

It would be interesting to see what it looks like under a clear-coat. | |

| | |

Joined:

October 2012

Posts: 1093

Location: Yokohama, Japan | DanSavage - 2016-05-21 2:51 AM

Very cool, Ken. Nice job.

I kind of like the rustic look the top has in that last pic. I also think it looks cool with just the holes sans epaulets.

It would be interesting to see what it looks like under a clear-coat. Thanks Dan! So....this is what ebonized spruce looks like!

I really like it. As I'm sure most of you all in the BFLG know, ebonizing is basically iron acetate reacting with "tannins" that are naturally found in wood. Spruce is not really known for its tannin content, so treating the wood with super concetrated coffee or tea helps to darken the wood. It gives the wood that nice rustic "faux" look. One of the reasons for returning to the original sound board for this project is the tap tone. The two sets of new AA Sitka that I purchased from Stewmac were actually nice pieces, but the tap tone was just not the same - probably because this sound board from 1990 is 26 years-old and fully seasoned. Maybe similar to Dans torrefied sound boards? However, because the spruce is 26 years-old, there is practically very little tannin content in the wood. For this project I brewed some super concentrated espresso and applied it to the sound board. After the espresso dried, the iron acetate was applied and the reaction was immediate. In the photo above, the sound board is still wet, and it should be a fair representation of what the guitar will look like after the final finish is applied. I'll let the sound board dry out completely for a week or more, then seal the stain before proceeding... Was worried that mixing concentrated espresso with iron acetate (essentially steel wool melted in vinegar) would cause an unbearable odor; but alas, after keeping both in a sealed container for over two weeks, the odor was practically non-existent. Cool!

Edited by arumako 2016-05-22 10:39 AM

| |

| | |

Joined:

February 2013

Posts: 177

Location: near Cologne/Germany | Really interesting and amazing, what skilled people are able to do....

Keep it goin'! | |

| | |

Joined:

June 2012

Posts: 2344

Location: Pueblo West, CO | Ken, Thanks for the info about the staining process. It's always good to learn about new techniques. I'll give it a try on some scrap pieces of spruce I've got in the shop. WRT the tap tones of the new wood, keep in mind that until the wood is jointed and thickness sanded you don't really get an idea of how it's going to sound. It changes again once the braces are glued to it. No doubt the older wood is going to sound better than the new wood. But, until you've actually built the top, it's difficult to make a comparison between a fully-built top and bare stock. Re-topping the few guitars I have done has given me a little (and only just a little bit) of insight into how much the tap tone can change as the top building process continues. arumako - 2016-05-22 8:32 AM One of the reasons for returning to the original sound board for this project is the tap tone. The two sets of new AA Sitka that I purchased from Stewmac were actually nice pieces, but the tap tone was just not the same - probably because this sound board from 1990 is 26 years-old and fully seasoned. Maybe similar to Dans torrefied sound boards? | |

| | |

Joined:

October 2014

Posts: 270

| I can see why the tap tone would change as construction continues but, all things being equal, is the best tap tone bare stock just going to get better or is a piece with a poorer initial tap tone going to surpass a piece with better initial tap tone after jointing and adding braces? | |

| | |

Joined:

June 2012

Posts: 2344

Location: Pueblo West, CO | Again, my experience is pretty limited, but from what I've seen so far, tap tones will get better (more resonant, or bell-like) as construction continues.

So, by knowing what the finished piece started off sounding like and how it sounded when completed, it's possible to closely estimate a good piece of bare stock the next time around.

| |

| | |

Joined:

October 2012

Posts: 1093

Location: Yokohama, Japan | Thanks Dan & great question BCam. I'll closely monitor tap-tone changes in the build of each of the two AA Sitka bare stock that I bought. Interestingly enough, they both have different tap tones. This is my first time really even considering "tap-tone"; but it is a mysterious and wonderful component of guitar voicing. One of them will be used to re-top my work horse 12-string, and the other will be used to re-top my Kramer Ferrington fretless bass.

Gives me a deep appreciation for the folks at the Mother Ship who've consistently selected excellent sound board material. Even my 1861 (grade A Sitka) sounds amazing!

DanSavage - 2016-05-22 6:07 AM Ken, Thanks for the info about the staining process. It's always good to learn about new techniques. I'll give it a try on some scrap pieces of spruce I've got in the shop. Thanks for mentioning that Dan, I didn't document the various samples that I practiced on, but it's really important. You could easily spill some iron acetate into the soundhole of the guitar and ruin the label forever. FWIW, I practiced ebonizing on rosewood, spruce, pine and maple BEFORE I took to the 1868! I probably don't need to mention this, but my iron acetate is made from "000" grade steel wool placed in a jar of vinegar. Since, I'm in Japan, I use rice vinegar, but distilled vinegar is probably better for most applications because it is colorless. The chemical reaction between the steel wool and the acids in the vinegar create the acetate, but the reaction requires that the top of the jar be "Unsealed" to allow the gases to release; otherwise...EXPLOSION! I sealed the jar after the reactions settled and waited about two-weeks. Oh yeah, you should also wash your steel wool with unscented plain dish washing soap thoroughly before combining with vinegar. I don't know about the States, but in Japan most brands of steel wool have lots of oil residue. Depending on the wood (tannin content) and the intensity of the stain desired, some folks dilute the acetate with water before application. Some of my sample woods turned deep amber (because of the rust particles and no coffee) while others just turned black...still others hardly changed colors or had different shades of black. Some came out splochy and messy. In any case, experimenting with this stuff is great fun! Here's the top after drying over night... I think I'm going to keep the epis on this 1868, but some variation in binding and purfling might be in order here! Woohoo!

Edited by arumako 2016-05-22 8:41 PM

| |

| | |

Joined:

December 2015

Posts: 287

Location: Katmandu | I find it great that you decided to reinstate the old top again; not a fan at all of the "greywash" though. | |

| | |

Joined:

October 2012

Posts: 1093

Location: Yokohama, Japan | leonardmccoy - 2016-05-22 2:08 PM

I find it great that you decided to reinstate the old top again; not a fan at all of the "greywash" though.

Thanks leonardmccoy! I originally thought wetting and drying the top would just ruin its integrity after a while (like plastic). I'm really glad I did my homework. It would have been a total waste to toss a 26-year old vintage solid Sitka spruce top!

As for the "ebonizing", well I hope the cringe factor is not unbearable for you! By the time I'm done with this thing you may not "be a fan of 'greywash'", but hopefully it won't be at the very bottom of your list of guitar finishes (like the DJ Ashba stuff...oops, I apologize if that's in any of your "fav" category)! Once the epi's are in place and I install the binding and purfling, you "maybe" pleasantly surprised? Of course, for the "natural finish purist" that may never happen, but...I'm just hoping I don't botch this thing up completely somewhere along the line...Lord help me!

Edited by arumako 2016-05-23 6:56 PM

| |

| | |

Joined:

October 2012

Posts: 1093

Location: Yokohama, Japan | Just waiting to apply the sanding sealer, and...

dreaming of just the right bling... Cream binding with gold (brass)/black/brass trim. Getting closer! | |

| | |

Joined:

June 2012

Posts: 2344

Location: Pueblo West, CO | That's turning out to be a really pretty guitar, Ken. | |

| | |

Joined:

October 2012

Posts: 1093

Location: Yokohama, Japan | Thanks Dan. Been working up the courage to move forward with this project. Since my CC54i iDea Project is on-hold (waiting for some parts to arrive), I decided to get back to work on this Elite. Three coats of sanding sealer brought out the beauty of the ebonized sound board. It also protects the wood and finish from any scratching that might come about from usage of the Dremel plunge router. So, it's time to route the epi slots in the sound board.

The first order of business is alignment. The new epis that Mr. Budny of Mother Ship fame sent me has some nice pre-drilled alignment holes. So to take advantage of these markers, the sound board was covered with pink masking tape, the center of the holes in the sound board were marked with easily visible blue ink. Once the marker holes were aligned with the blue center markers, it was easy to trace the outside of the epis.

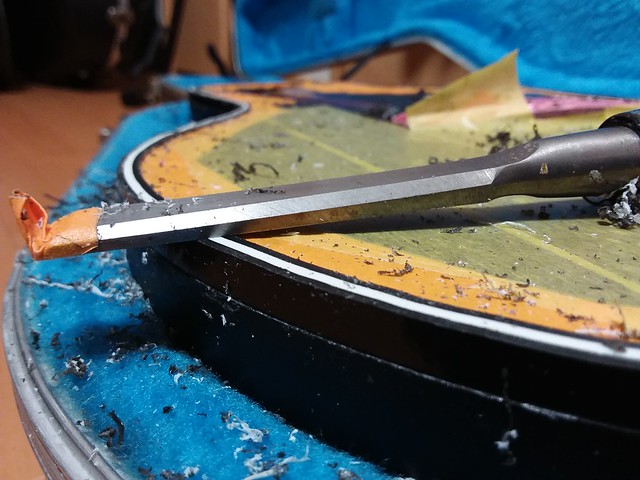

The outside edges of the epis were traced on the masking tape and I used an exacto to cut out the shape of the epis, The process was painstakingly slow...

After a bunch of dry runs and practice runs... onto routing with my plunge router! The spruce sound board was surprisingly challenging to route. While I routed in the direction "with the grain", the sound board seemed to be softer in some areas and harder in others, interesting. After my first rough cut, I felt a bit relieved...

Edging the epi holes required a lot of time and concentration! Whew...intense!

After the final cut, I stuffed some newspaper into the bowl (in case the epoxy spills into the bowl or onto the label) and applied Z-Poxy 30-minute Epoxy into the epi slots routed into the sound board. Put a sheet of saran wrap on top of the epis and weighed the whole thing down and in place! Cool!

...and now, for the treacherous 48 hour wait! Don't touch the assembly, Ken! Oh, hurry, hurry, hurry!

Edited by arumako 2016-07-18 11:31 AM

| |

| | |

Joined:

September 2012

Posts: 815

Location: Thredbo, NSW, Australia | Wow! I'm looking forward to seeing the weights come off. | |

| | |

Joined:

May 2011

Posts: 760

Location: Muenster/Germany | The special neck joint, the dark guitar top and the idea of inlaid epis are phantastic! Will finally look much better than any original Ovation. I wish my Elite had inlaid epis. too.( I made similar hand-made routings before, it´s really rough going. I decided to value it as worthwhile experience, but spend my time on other things in the future;-) ) | |

| | |

Joined:

October 2012

Posts: 1093

Location: Yokohama, Japan | My goodness, it has been hard to get some time-in "edgewise" to make progress on my 1868! Alas, the weights have come off, and was able to get some preliminary sanding and scraping to prepare for another three to four coats of sanding sealer. No need to worry about the scratches around the epi's, they'll disappear with more sealer coats. Just got everything set-up and ready to go. Needed to make sure the paint wasn't going to get all over the bowl and binding/purfling channels...

I used the leveler to make sure I was spraying onto a completely flat surface. Needed to make sure the thin coats of sanding sealer wouldn't pile up in corners. It's been a while since I put my airbrush to work. This is for small plastic models and is really not suited for this big of a job, but didn't feel like forkin' out the bucks to get a new one; and this little unit forces me to manage my spraying better, it also uses a "can" compressor!

After "goin' to school" on Dan's 1617 Rebuild, I decided to use a nitrocellulose lacquer sanding sealer. Was a bit worried about using Japanese products, but it turns out the stuff is really really good (finishes evenly, fills gaps, and finishes very clear). It also dried to the touch in about 5 minutes. Whoa! I wasn't expecting that! Probably because of the thin coats? The neck extension was also cleaned up to prepare for reassembly.

After three light coats the sealer looked to be in pretty good shape. Gotta stop at this point for today, but the top needs another three coats or so; however, the binding and purfling will need to be installed first, followed by opening up the multiple epi sound holes, then three additional thin coats of sealer, and finally on to the final finish. Planning on staying with a lacquer clear coat. Apparently, the company that makes this sealer makes a killer "clear coat" as well. One interesting note is that the ebonized top looks black under certain lighting and brown under others! Wow, that was also an unexpected result.

Isn't that just too cool? I'm hoping the final lacquer coat can maintain this feature. Getting closer and closer...don't mess-up, Ken! Please don't mess-up!

Edited by arumako 2016-07-28 8:50 AM

| |

| | |

Joined:

September 2012

Posts: 815

Location: Thredbo, NSW, Australia | This is coming along nicely Ken.

I'm enjoying this rebuild and I'm looking forward to hearing and seeing the final result. | |

| | |

Joined:

October 2012

Posts: 1093

Location: Yokohama, Japan | BanjoJ - 2016-07-29 6:21 AM

This is coming along nicely Ken.

I'm enjoying this rebuild and I'm looking forward to hearing and seeing the final result.

Grateful for your encouraging comments BanjoJ! Applying binding and purfling is a new endeavor for me, so I need to take the next few steps thoughtfully and carefully!

DetlefMichel - 2016-07-18 6:11 PM

The special neck joint, the dark guitar top and the idea of inlaid epis are phantastic! Will finally look much better than any original Ovation. I wish my Elite had inlaid epis. too.( I made similar hand-made routings before, it´s really rough going. I decided to value it as worthwhile experience, but spend my time on other things in the future;-) )

Thanks DetlefMichel! Just to clarify, the special neck joint is for my CC54i Project that I'm currently working on in a parallel thread. For my 1868, the original neck just needs to be cleaned and reinstalled. A dry install tells me the neck angle is perfect as is! As far as the final look goes, I think it's gonna look really good; but as it turns out, I'm pretty much copying the 1984 Collector's Edition. The following pic is none other than Damon67's '84 Collector's (hope you don't mind my borrowing your pic from your website Damon67).

She's magnificent isn't she? There's no way, mines gonna look this nice! But, if I can get mine half as nice, I'll be satisfied. Since, my 1868 originated from the Mother Ship, it's going to sound magnificent, as long as I don't mess up on the re-assembly. The look of the inlaid epis is quite nice. However, for an amateur tinkerer like me, it takes an enormous amount of concentration and time. Your conclusion - "worthwhile experience, but time better spent on other things" - hits the nail on the head! The other factor is the final bling. Messing up on binding and purfling selection could make my 1868 look outright fugly. Can't seem to settle on just the right bling. Wanted to go with something different from the white/orange/white scheme. Currently thinking Maple (wood)/Gold (brass)/Black (pvc)/Gold/Maple. I can order direct from Stemac now, and their shipping costs to Japan are pretty reasonable, so some bling is on the way. Just never really exceled at design and color combinations and stuff, so I'll be consulting my son and daughter for that kind of advice! Again, thanks for the encouragement comments and the suggestions along the way!

Edited by arumako 2016-07-29 5:19 PM

| |

| | |

Joined:

May 2008

Posts: 1565

Location: Indiana | Great job, Ken. | |

| | |

Joined:

October 2012

Posts: 1093

Location: Yokohama, Japan | Thanks Jonmarkstone! Not going to rush it, but I should be done in a week or two! BFLG encouragement is definitely providing the momentum! | |

| | |

Joined:

October 2016

Posts: 21

Location: NJ, USA | Hi arumako, I think I can help with your question about the wood laminate on the underside of the top at the upper bout. While researching Ovation's elite models I came across some info from their 1987 catalog that says this about the elites:

"With its Adamas-derived, Quintad II brace pattern, the top is 0.100" thick overall and constructed from our best grade spruce reinforced with birch veneer in the upper bout for outstanding highs"

Check out the 5th image down at this link. Hope this helps! | |

| | |

Joined:

October 2012

Posts: 1093

Location: Yokohama, Japan | Hi davegardnerp0. Thanks for the link. That's it isn't it! A birch veneer! Cool, and all along I thought it was pine. It's really interesting that the birch veneer helps to accentuate the higher frequencies! Who'd a guessed that? I only have the binding and finishing to complete on this 1868. Unfortunately this project, like all my others are on hold right now. Just dyin' to finish up. Even in the condition she's in, the '90 AA Spruce top has excellent tap tone. Thanks again for finding and sharing that info! | |

| | |

Joined:

October 2012

Posts: 1093

Location: Yokohama, Japan | Well...two and a half years into this project, and still going no where! Was able to squeeze in just enough time to open up the epi's on the sound board; so I thought I'd update this thread... Really glad to have reverted to the original top, but that means the epi holes in the sound board already exist; however, I need to drill the holes in the epi's themselves. Misalignment could be disastrous. Fortunately, I kept the original epi's for reference, and they served perfectly as a hole alignment jig...

It's very interesting to note that the new epi's from the Mother and the original epi's are slightly different in shape. However, the hole alignments are exact. Had I installed a completely new sound board, I could just drill right through the epi and sound board. However, in this process that would pose a high misalignment risk. I had to approach shaping the epi's in a different way.

Some guide holes were drilled based on the original epi alignment jig. My trusty Dremel with the small routing bit was called into service. Needed to use slow speeds and work real slow. The bit was placed into the guide hole and rotated into bigger and bigger concentric circles. The cut was really challenging because of the different wood types used in the epis. The light inside the bowl helped me to see the edge of the original epi hole cut in the sound board. To allow for some "room for error", I practiced on the bigger epi holes, and after that I focused on the smaller ones. After some successful practice runs, I jumped into the cutaway epi.

After verifying consistency in method, I jumped right into the bass side epi's.

Needed some serious concentration, but the final results were acceptable. Right now, the epi's look more like one of the Asian Celebrity models as the circles are not perfect and will need to be sanded down; however, the results are satisfactory for now. I also found that my clamping method did not fully secure the epi's into their respective sound board cavities. I'll need to fill the very thin gaps with some king of adhesive to ensure there is no buzzing. It'll still be a while before I get this completely finished, but it feels good to get back into the fray after a long hiatus, and the sound board seems to be resonanting quite a bit when I tap it. Can't wait to get this baby done! | |

| | |

Joined:

June 2012

Posts: 2344

Location: Pueblo West, CO | Thanks for the update, Ken.

Looking good. It's getting there. | |

| | |

Joined:

October 2012

Posts: 1093

Location: Yokohama, Japan | Thanks Dan! Nothing like your brother's "Ultimate" Ultra, but I think I'll be able to finish her up in the summer (famous last words!). I decided to simplify and put aside the nice exotic wood bindings (save those for when I'm a bit more experienced with this stuff) and ordered some standard plastic ones - they'll arrive tomorrow. As I was verifying the neck alignment, I noticed the frets really need some attention; so I've been wanting to try some Warwick brass alloy frets that I got awhile back (alternative for EVO Golds??? - worried about that green discoloration). I heard they add some interesting timbre to the guitars voice.

Thanks to you and the OFC, my fret work is done "in-house" now (saves a lot of mulla), and I'm really itching to get this thing done. Not even close to the quality of your work, but I'm kinda feeling like your on-line apprentice by correspondence! | |

| | |

Joined:

October 2012

Posts: 1093

Location: Yokohama, Japan | ...Well, I couldn't stop workin' on this thing (yeah, it's gonna come back at me in spades!) Oh well...took the frets off; and although fret wear was not bad at all, some frets were popping out of the slot, and the Warwick brass frets look pretty neat...

One thing that seems kind of odd is how the rosewood grains on the fret board are standing up...like it got too much moisture at one point. It looks almost like some oil was rubbed into the fret board... Anyway, this fret board is going to be leveled down to a 20" radius before the refret. The Warwicks are not as shiny as the EVO Golds. It's gonna be interesting how these frets affect the tone of this guitar; of course, having never been in playable condition, I have nothing to compare it to...Lol. | |

| | |

Joined:

September 2012

Posts: 815

Location: Thredbo, NSW, Australia | Nice work Ken. The new epis look great!

The fretboard will come up nicely I'm sure. | |

| | |

Joined:

June 2012

Posts: 2344

Location: Pueblo West, CO | arumako - 2017-05-02 7:06 PM

Thanks Dan! Nothing like your brother's "Ultimate" Ultra, but I think I'll be able to finish her up in the summer (famous last words!). I decided to simplify and put aside the nice exotic wood bindings (save those for when I'm a bit more experienced with this stuff) and ordered some standard plastic ones - they'll arrive tomorrow. As I was verifying the neck alignment, I noticed the frets really need some attention; so I've been wanting to try some Warwick brass alloy frets that I got awhile back (alternative for EVO Golds??? - worried about that green discoloration). I heard they add some interesting timbre to the guitars voice.

Thanks to you and the OFC, my fret work is done "in-house" now (saves a lot of mulla), and I'm really itching to get this thing done. Not even close to the quality of your work, but I'm kinda feeling like your on-line apprentice by correspondence!

Thanks for the kind words, Ken.

I've read some good things about the Warwick bell brass frets. I think the green discoloration is simply tarnishing of the surface which will go away when you dress the frets.

Plus, working on my own guitar gives me a sense of pride to be able to say that I did such and such work myself, and now I'm able to enjoy the fruits of my labors. I got the same enjoyment from designing/building and then flying the models I designed and built.

Thanks again.

Dan | |

| | |

Joined:

June 2012

Posts: 2344

Location: Pueblo West, CO | arumako - 2017-05-02 11:49 PM

...Well, I couldn't stop workin' on this thing (yeah, it's gonna come back at me in spades!) Oh well...took the frets off; and although fret wear was not bad at all, some frets were popping out of the slot, and the Warwick brass frets look pretty neat...