|

|

Joined:

May 2006

Posts: 4236

Location: Steeler Nation, Hudson Valley Contingent | There is a pretty interesting thread on the AGF about Ovation repairs and info. You can find it here. The topic of the Adamas suspension ring came up with two interesting consequences: 1.) Someone found a really cool photo of it that clearly shows how it works. I've only seen diagrams before.

And 2.) They asked a question I never thought of before. Specifically. What is the ring made of? All of which also made me wonder; how is it manufactured exactly? Is it placed on the rim of the bowl as one piece or assembled a bit at a time? I know a bit about Adamii, but am certainly no expert. I'm looking forward to how this thread pans out. |

|

| |

|

Joined:

September 2011

Posts: 59

| Patch...

That picture helps me understand the glue repair I just made on the 1681 I recently acquired.

Apparently in my case the suspension had separated from the body from the impact. From the outside I glued what I guess I would call the binding back down to the bowl and then glued the lower edge of the ring to the body.

Is this picture valid for my 1981 model?

Great picture. Has that picture been floating around in cyberspace for a while? |

|

| |

|

Joined:

May 2006

Posts: 4236

Location: Steeler Nation, Hudson Valley Contingent | I dunno Carl. That's the first time I've seen it. It is a cool photo.

I only have one guitar with a ring on it, so I'll let those who know more than me about it weigh in. My foot's been in my mouth enough recently.  |

|

| |

|

Joined:

May 2006

Posts: 4236

Location: Steeler Nation, Hudson Valley Contingent | So does anyone have any info they can add? |

|

| |

|

Joined:

April 2008

Posts: 2985

Location: Sydney, Australia | I'm not even sure which bit in the picture is actually the ring? Is the the little vertical whiteish strip, or the whole brown bit the top is resting on? Two of my adamii have a suspension ring (1680 and 08C) and one doesn't (1685). The visual difference is a little silver strip in between the top and the binding, which suggests that the little white bit in the picture is the ring. Can someone clarify that? |

|

| |

|

Joined:

December 2001

Posts: 7246

Location: The Great Pacific Northwest |

The "ring" is essentially the part with the decoration. This photo shows THREE basic parts.. - The "top" is the part with the horizontal stripe. That's the piece of wood sandwiched between the Carbon Fiber

- The decorative part has the decoration, and if you look carefully, there is a shelf that the top is sitting on, and an edge that goes on the inside of the bowl.

- The outside part is the bowl.

If I remember correctly, and someone could check at a video of the factory tour, the "ring" comes as part of the back/same material. This is from memory so someone should check me on this, but the ring serves as support during transport to the factory, then it is removed from the bowl. It may be upside down in the bowl at this point and attached like old plastic model parts used to attach to a frame. At the factory it is removed from the bowl and the attachment points cleaned/removed, flipped and set into the bowl with the top. This may not be exactly how it's done, but if someone can find a factory tour video to link to, it should cover the bits I may have not gotten correct. |

|

| |

|

Joined:

May 2006

Posts: 4236

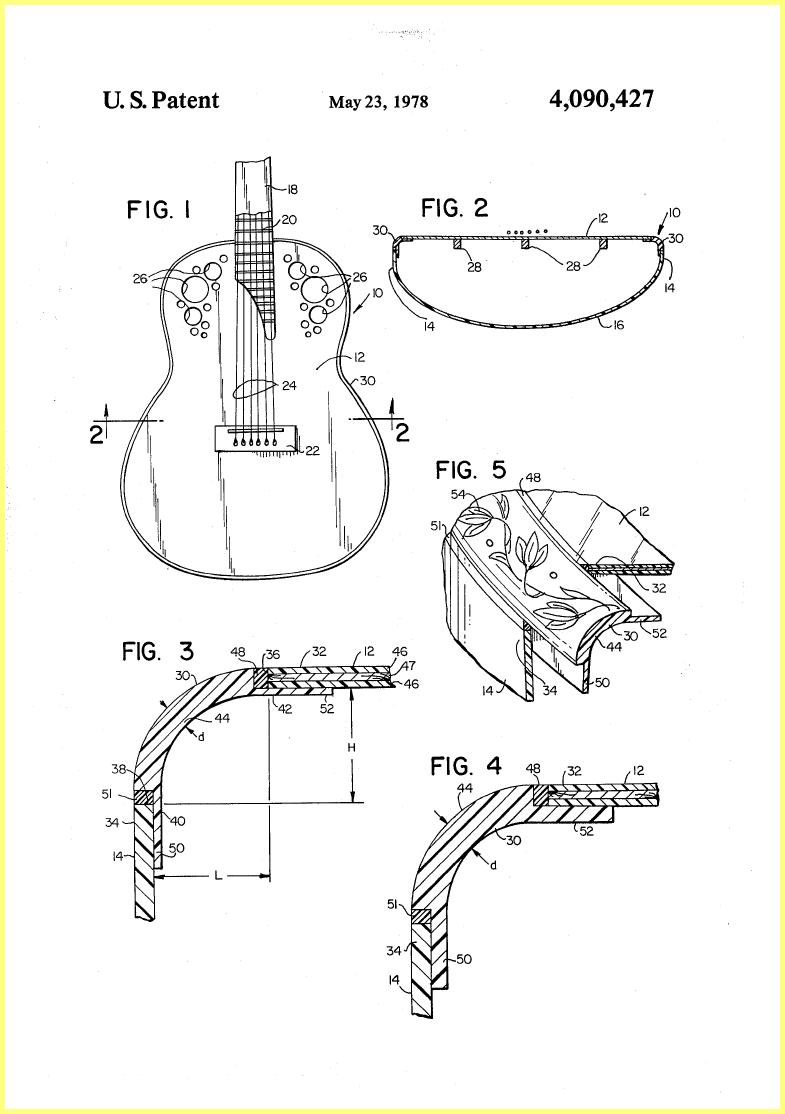

Location: Steeler Nation, Hudson Valley Contingent | TAFKAR, here's the patent drawing for the suspension ring, courtesy of Ovation Tribute.

|

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | patchmcg - 2013-05-18 5:20 PM And 2.) They asked a question I never thought of before. Specifically. What is the ring made of? All of which also made me wonder; how is it manufactured exactly? Is it placed on the rim of the bowl as one piece or assembled a bit at a time? I know a bit about Adamii, but am certainly no expert. I'm looking forward to how this thread pans out. The text of the patent can be found at: Patent US4090427. It would appear that the suspension ring is molded from resin and fiberglass, probably unidirectional rather than woven cloth. Referring to FIG. 3, taken on a plane perpendicular to the longitudinal axis of its mountng member, the top plate marginal edge 36 is space a substantial distance L inboard of the adjacent sidewall upper portion 34, and the top plate marginal portion 32 is likewise space a substantial distance H above the sidewall top edge 38. The mounting member 30 has an inboard longitudinal edge portion 40 fixed to the sidewall upper portion 34, an inboard longitudinal edge portion 42 fixed to the marginal edge portion 32 of the top plate, and an intermediate portion 44, of curved shape and of a substantially uniform thickness d, extending from the edge portion 40 to the edge portion 42. In the illustrated case, the distances H and L are substantially equal and the mounting member intermediate portion 44 has an arcuate shape as seen in FIG. 3. Also as shown in FIG. 3, the top plate 12 is of a laminated consturction and may be one wherein the face plies 46,46 are made of a composite material consisting of graphite fibers and resin, and wherein its middle ply 47 is made of wood, as described in previously mentioned U.S. Pat. No. 3,880,040. A purfling strip 48 is inserted between the top plate marginal edge 36 and the mounting member portion 44, for decorative purposes, and a similar purfling strip 51 is also inserted between the upper edge 38 of the sidewall and the mounting member portion 44. The inboard longitudinal edge portion 40 of the mounting member is in the form of a vertical lip 50 defining, with the thicker portion 44, a rabbet receiving the upper edge portion 34 of the sidewall and the purfling strip 51, the lip 50 being fixed to the upper edge portion 34 by a suitable adhesive. Likewise, the inboard edge portion 42 of the intermediate member 30 is in the form of a horizontally extending lip 52 adhesively secured to the marginal edge portion 32 of the top plate, the lip 52 with the portion 44 defining a rabbet for receiving the marginal edge portion 32 along with the associated purfling strip 48. The thickness d of the mounting member portion 44 is relatively small in comparison to the distance L, and the material of the mounting member is such, so that the marginal edge portion 32 of the top plate may vibrate vertically relative to the sidewall 14 through accompanying resilient bending of the mounting member portion 44. Preferably the dimension d is substaintially less than one half the dimension L and the material of the intermediate member is a resilient moldable one consisting at least in part of plastic. For example, in a guitar body the dimension d may be approximately 0.075 inch, the dimension L may be approximately 0.250 inch and the material of the mounting member may be a composite material consisting of fiberglass fibers bonded in a resin matrix. From FIG. 3 it will be understood that by varying the dimension d of the intermediate portion 44 of the mounting member, the springiness of the mounting member, with respect to vertical vibration of the top plate marginal edge portion relative to the sidewall, may be varied by varying the dimension d. FIG. 4, for example, is similar to FIG. 3 except for showing a mounting member 30 in which the dimension d of its intermediate portion 44 is greater than the thickness of the corresponding portion of FIG. 3. Accordingly, the mounting member on FIG. 4 has greater rigidity, or less springiness, than that of FIG. 3. Springiness of the mounting member 30 has an influence on the natural frequency of the top plate 12. Therefore, by matching a particular top plate with a mounting member having a particular thickness d (and accordingly a particular springiness) a given desired natural frequency of the top plate, as installed in the body, may be obtained. Further, the mounting member 30 of this invention, as will be evident from the drawing figures, has a rounded outside surface giving the edge of the instrument body, along the margin of the top plate, a comfortable rounded shape which contrasts with the corresponding sharp edge normally appearing on previous instrument bodies of conventional consturction. Also, the mounting member is preferably made as a one piece molded ring. Therefore, in the molding process for making it a decorative design, such as indicated at 54 in FIG. 5, may be readily molded into its outside surface. |

|

| |

|

Joined:

May 2006

Posts: 4236

Location: Steeler Nation, Hudson Valley Contingent | Thanks Dan! That's perfect! I learned something new today.

Edited by Patch 2013-05-22 10:17 AM

|

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | Thank you for starting the thread and posting the pic.

I often wondered exactly how the suspension ring is attached to the bowl and how it carried the top. The cross-section pic answered that question.

|

|

| |

|

Joined:

March 2010

Posts: 486

Location: Suisun City, Ca | Cool. One thing I don't see, and don't understand from those prints, is how is the top section 32 held down to the rabbited section 52? They don't seem to mention that. I always heard that his was the "secret" to Adamas' great ability to vibrate, ( Floating top) but it has to be secured down to the side/mounting member, whatever, doesn't it? This really bothers the old Boilermaker in me. |

|

| |

|

Joined:

April 2010

Posts: 823

Location: sitting at my computer | AstroDan - ...how is the top section 32 held down to the rabbited section 52? McDonald's secret sauce?  |

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | AstroDan - 2013-05-22 12:55 PM

Cool. One thing I don't see, and don't understand from those prints, is how is the top section 32 held down to the rabbited section 52? They don't seem to mention that. I always heard that his was the "secret" to Adamas' great ability to vibrate, ( Floating top) but it has to be secured down to the side/mounting member, whatever, doesn't it? This really bothers the old Boilermaker in me. I think it's just glued down: The inboard longitudinal edge portion 40 of the mounting member is in the form of a vertical lip 50 defining, with the thicker portion 44, a rabbet receiving the upper edge portion 34 of the sidewall and the purfling strip 51, the lip 50 being fixed to the upper edge portion 34 by a suitable adhesive. Likewise, the inboard edge portion 42 of the intermediate member 30 is in the form of a horizontally extending lip 52 adhesively secured to the marginal edge portion 32 of the top plate, the lip 52 with the portion 44 defining a rabbet for receiving the marginal edge portion 32 along with the associated purfling strip 48.

Edited by DanSavage 2013-05-22 4:32 PM

|

|

| |

|

Joined:

March 2010

Posts: 486

Location: Suisun City, Ca | DanSavage - 2013-05-22 4:30 PM AstroDan - 2013-05-22 12:55 PM

Cool. One thing I don't see, and don't understand from those prints, is how is the top section 32 held down to the rabbited section 52? They don't seem to mention that. I always heard that his was the "secret" to Adamas' great ability to vibrate, ( Floating top) but it has to be secured down to the side/mounting member, whatever, doesn't it? This really bothers the old Boilermaker in me. I think it's just glued down: The inboard longitudinal edge portion 40 of the mounting member is in the form of a vertical lip 50 defining, with the thicker portion 44, a rabbet receiving the upper edge portion 34 of the sidewall and the purfling strip 51, the lip 50 being fixed to the upper edge portion 34 by a suitable adhesive. Likewise, the inboard edge portion 42 of the intermediate member 30 is in the form of a horizontally extending lip 52 adhesively secured to the marginal edge portion 32 of the top plate, the lip 52 with the portion 44 defining a rabbet for receiving the marginal edge portion 32 along with the associated purfling strip 48. Ahhh. I see that. I guess it was never a "floating" top. |

|

| |

|

Joined:

April 2010

Posts: 823

Location: sitting at my computer | DanSavage - I think it's just glued down: Elmer's not-so-secret sauce.  |

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | AstroDan - 2013-05-22 3:11 PM Ahhh. I see that. I guess it was never a "floating" top. Compared to the how most tops are mounted, i.e.: firmly glued to the sides/kerfing, the tops glued to the suspension rings would actually 'float'. The tapered/radiused lower profile of the suspension ring, combined with the composite material used to mold it, is probably pretty flexible. The marginal edge portion of the top plate is spaced a substantial distance inboard of the top edge of the sidewall and the mounting member has an intermediate portion extending between the sidewall top edge and the top plate marginal edge with the intermediate portion having a relatively small thickness and being made of a resilient material so as to be deformable in a bending mode to accommodate vertical vibration of the top plate marginal edge portion relative to the sidewall. The springiness of the mounting member may be varied by varying the thickness of its intermediate portion, to suit the particular top plate with which it is used. Preferably, the mounting member is made of a molded plastic material, such a composite material consiting of fiberglass fibers and resin... |

|

| |

|

Joined:

June 2012

Posts: 2345

Location: Pueblo West, CO | SOBeach - 2013-05-22 4:49 PM

Elmer's not-so-secret sauce.

Yeah. Probably the super-duper hot-glue seen in the 2005 tour video. |

|

| |

|

Joined:

April 2010

Posts: 823

Location: sitting at my computer | patchmcg - All of which also made me wonder; how is it manufactured exactly? Patch, see the factory tour video that Al posted... http://ovationfanclub.com/megabbs/forums/thread-view.asp?tid=34690&posts=4#M472900 @ approx. - 20:10 "This is what we call a flex edge. ...this is our bonding surface for our carbon fiber." |

|

| |

|

Joined:

October 2013

Posts: 57

| Do all Adamas guitar have the flex edge ? I just got my 1597 and it doesn't look like it does. The edge looks like a strip of plastic like you'd find on any other guitar. |

|

| |

|

Joined:

March 2005

Posts: 12761

Location: Boise, Idaho | The Ute (U681t) has a regular white binding. It is a great sounding guitar without the suspension ring. Anyway, not all of the models have it. |

|

| |

|

Joined:

June 2002

Posts: 6202

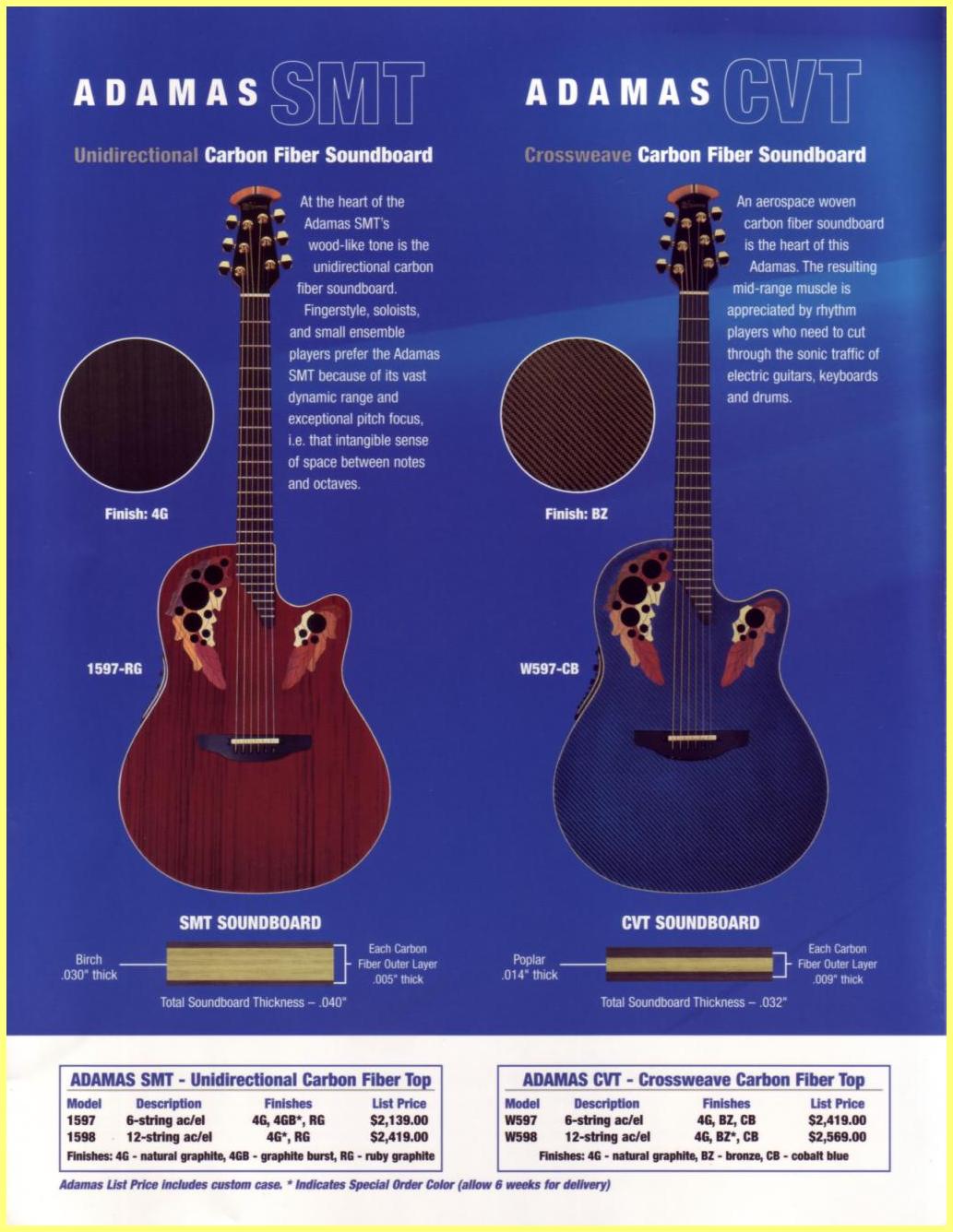

Location: Phoenix AZ | SMT and CVT style adamas do not have the suspended ring |

|

| |

|

Joined:

October 2013

Posts: 57

| Thanks for the answers, I was curious. I love that guitar though, great sound and so fun to play. |

|

| |

|

Joined:

August 2011

Posts: 887

Location: Always beautiful canyon country of Utah | At the risk of sounding like a novice/rookie what do SMT and CVT stand for?? |

|

| |

|

Joined:

September 2006

Posts: 10777

Location: Keepin' It Weird in Portland, OR | nerdydave - 2013-11-13 6:52 PM

At the risk of sounding like a novice/rookie what do SMT and CVT stand for??

SMT is one-directional carbon fiber sandwich. CVT is cross-weave carbon fiber sandwich.

Look here....

http://www.ovationtribute.com/Catalogues/2000_Jp_Adamas_Catalog/200...

and...

http://www.ovationtribute.com/Adamas_Models/04-Adamas_Other_Models/...

And all around Ovation Tribute for other fascinating tidbits.

|

|

| |

|

Joined:

August 2011

Posts: 887

Location: Always beautiful canyon country of Utah | But I have a 1681-9 which I was led to believe is SMT but it definitely has the suspension ring. What am I missing here?? |

|

| |

|

Joined:

September 2006

Posts: 10777

Location: Keepin' It Weird in Portland, OR | nerdydave asks, "But I have a 1681-9 which I was led to believe is SMT but it definitely has the suspension ring. What am I missing here??"

An SMT has a shiny top...

Your 1681 does not have a shiny top, does it?

Edited by Old Man Arthur 2013-11-14 9:31 PM

|

|

| |

|

Joined:

April 2008

Posts: 2985

Location: Sydney, Australia | I think that both have unidirectional carbon fibre tops, but the SMT has layer of varnish* on top. I don't know if they have the same tops apart from the varnish, Ovation seem to have a range of carbon fibre tops. The 1680 has a NWT top that has a piece of plywood inside, whereas others have a solid piece of timber inside the carbon fibre. It also appears from the graphic that OMA posted that they used different thicknesses of wood and carbon fibre (a new tidbit I learned today).

(*OK, it has a more technical name) |

|

| |

|

Joined:

August 2011

Posts: 887

Location: Always beautiful canyon country of Utah | Mine does not have a shiny top and thank you as always OMA for being your usual font of information. Good luck on yur busking. May the holiday spirit shine upon you and may those around you exhibit a generous heart!! |

|

| |

|

Joined:

December 2003

Posts: 855

Location: Canada | Standingovation - 2013-11-13 4:25 PM

SMT and CVT style adamas do not have the suspended ring

So which types of tops have the suspension ring then? |

|

| |

|

Joined:

March 2002

Posts: 15679

Location: SoCal | Adamii......? |

|

| |

|

Joined:

March 2005

Posts: 5567

Location: Blue Ridge Mountains | These construction details really show how much thought and science went into the design of the Adamas guitars in the beginning...as great as Ovation guitars are (and they are), there is truly nothing like the original carbon top/suspended ring Adamas guitars: those who have never played one (or owned one) are in for a real treat...I just love them. Thanks Patch for starting (reviving) this educational thread. Good Stuff! |

|

| |

|

Joined:

December 2003

Posts: 855

Location: Canada | MusicMishka - 2013-11-17 6:25 PM

These construction details really show how much thought and science went into the design of the Adamas guitars in the beginning...as great as Ovation guitars are (and they are), there is truly nothing like the original carbon top/suspended ring Adamas guitars:

So in other words - some newer Adamas do not have a suspension ring anymore? But for the 1681 the description states "Each top is precisely fitted with “AST” - Adamas Suspended Top - technology that allows the ultra-thin top to vibrate more freely than traditionally constructed acoustic guitars."

Edited by d'ovation 2013-11-18 10:30 AM

|

|

| |

Suspension ring question...

Suspension ring question... Suspension ring question...

Suspension ring question...